Glass Etching: cream vs blasting

Well another type of project I have been wanting to try since I got my Silhouette Cameo cutter was making vinyl masks to be used in laying over glass object for etching.

Verdict: blasting wins hands down IF you can do it, have the space/cabinet..etc

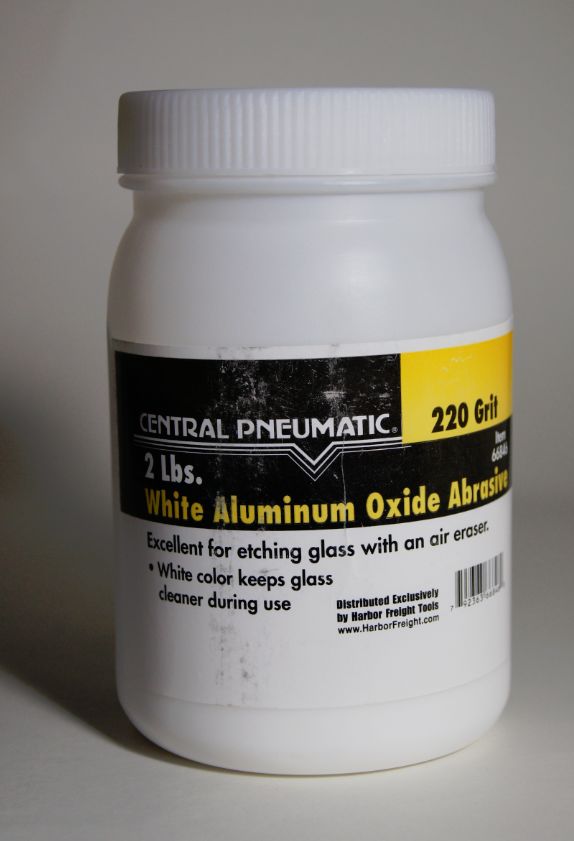

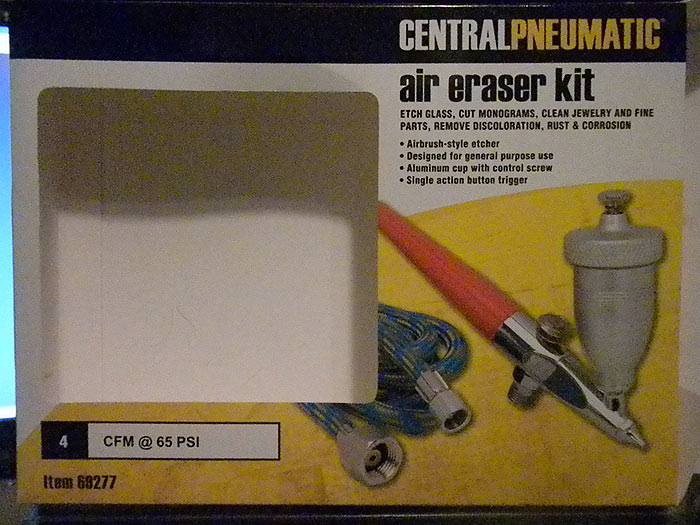

I used the ‘air eraser’.. and the media sold at HF. (my kit even came with a little bottle of it).. but I bought a bigger one for $10.00

It’s the stock aluminum oxide 220 grit I think

http://www.harborfreight.com/2-lbs-220-grit-white-aluminum-oxide-abrasive-66846.html

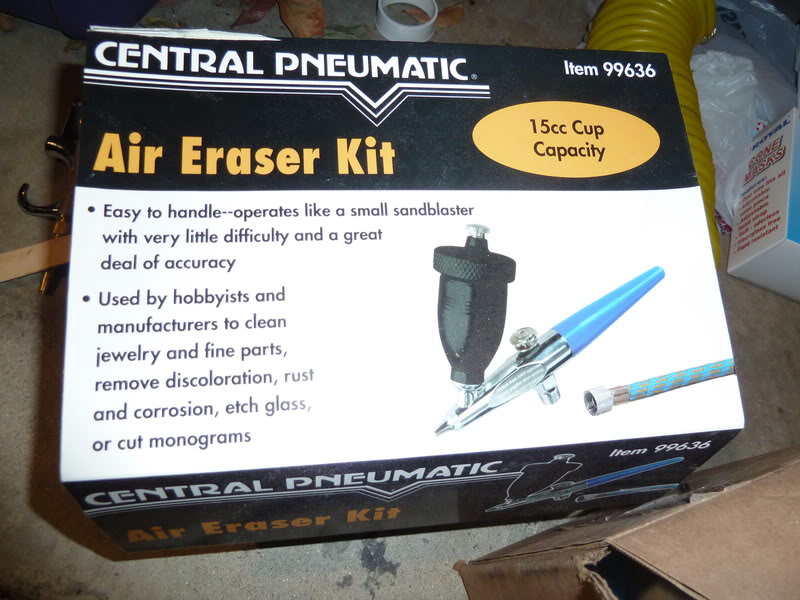

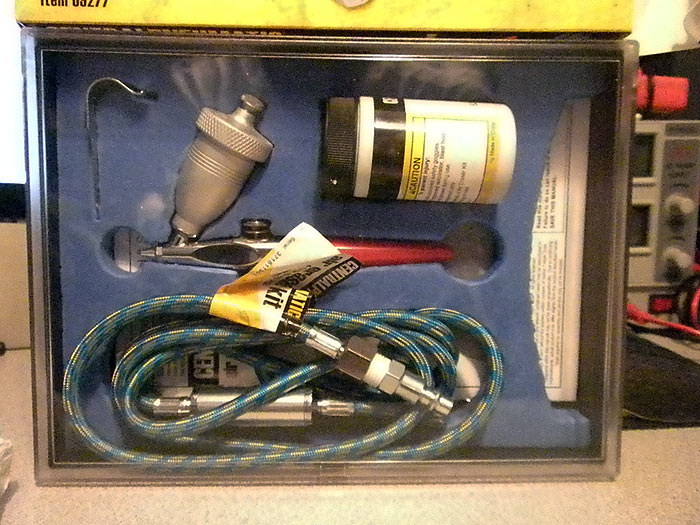

HarborFreight being the mess that it is.. actually has/had two kits when I went there..

A bunch of this one:

that look like nothing more than the gun & hose..

and waaaay in the back I saw a different box, which looked like real ‘kit’.. gun, hose, bottle of al. oxide abrasive, wall mount/hook, and crap-tastic face mask..lol

red body vs body gun for ‘quick’ sign of different kits.. (and part numbers)

according to HF though.. 1 or both are discontinued? (so who knows.. they don’t know much over there)

decent purchase for under $20.00USD … probably not as quality as more expensive ones.. but it works.. sometimes a quick shake to unclog media, but got the job done none the less.. J

As for the two etching styles I tested:

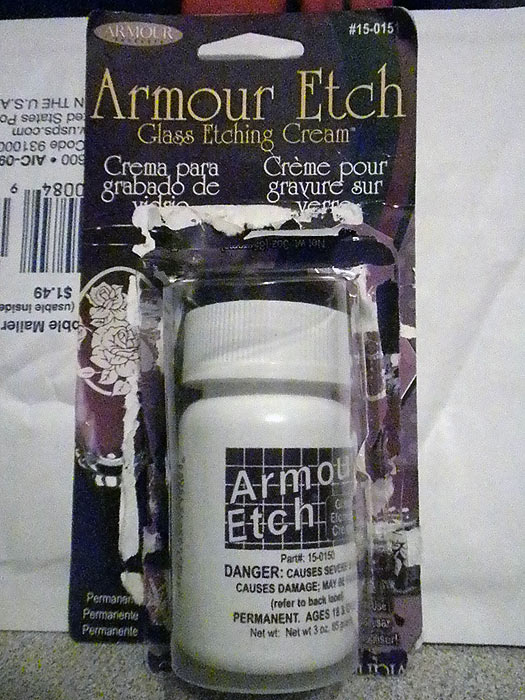

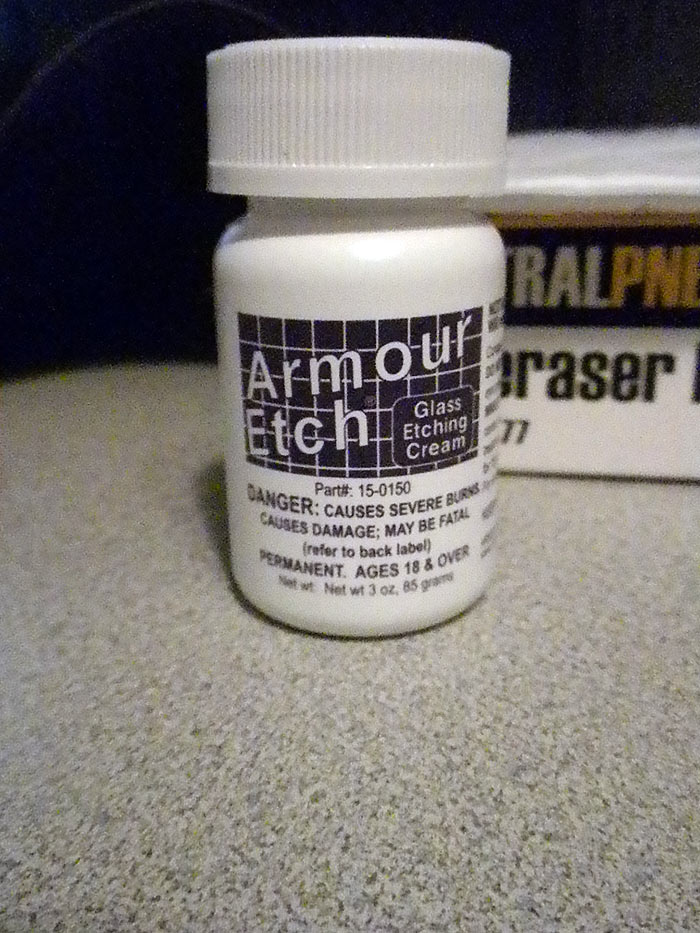

here is the cream I tried initially..

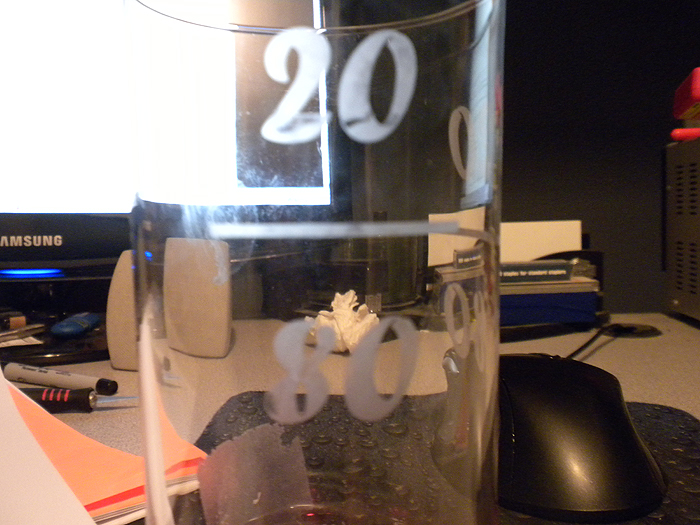

at first I thought the cream results were “OK”..

I had read about the non-uniform finish.. (lighter/darker/patchy in some areas..etc)..

I got the same thing()s/results.. however.. to be fair.. Im not sure if I didn’t have a CLEAN glass/surface to begin with.. or maybe some of the ‘stick’ (residue) from the painters tape/transfer paper was left on the glass in certain areas? Oil from fingers?.. using a cream, ALL of that can affect it… so I don’t want to blame it ALL on the cream

So I was like ‘meh’ (might have potential if I can be more careful., was definitely easy & fast and required little prep/clean-up..etc)

RESULTS:

**I put the cream on fairly THICK.. and left it on for 4+ minutes.. (the recommended time is 60 seconds)

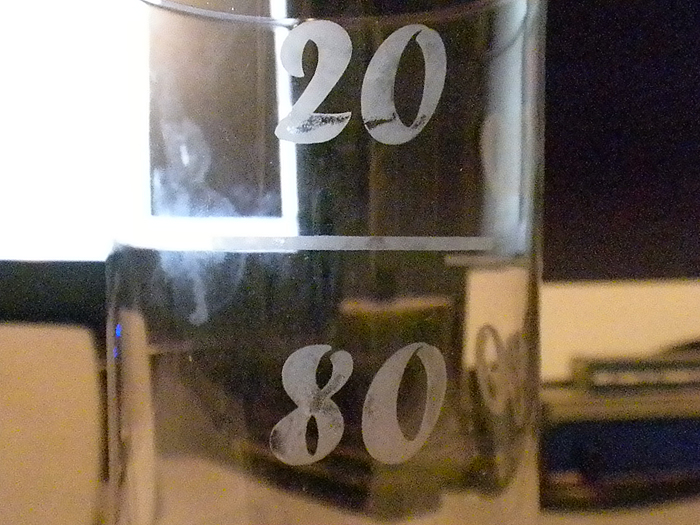

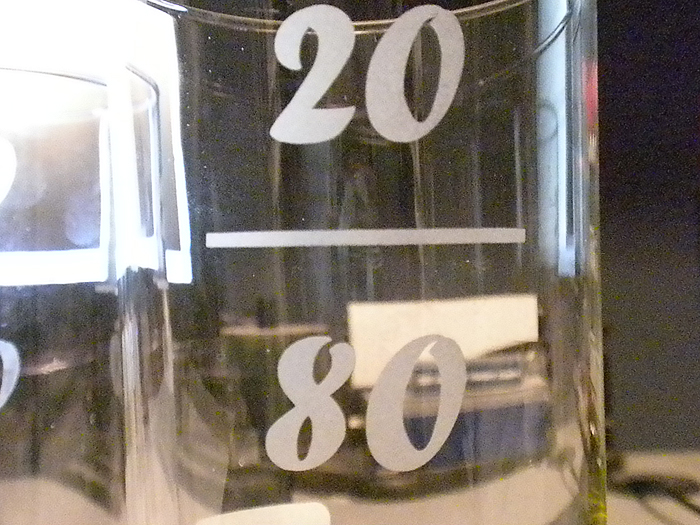

When I tried the blasting method.. the results were MUCH better and, if can be done, is the method “I” would choose/do every time.

Darker, more uniform ‘etch’ is left.. decent edges as well.. (even on the 10+ font at bottom)

RESULTS:

overall the blasting is BEST IMHO… but the cream ‘does’ work ok. Its great to be able to have this ability/option now..

Silhouette Cameo + etching cream/air eraser + Dollar Store = great, cheap gifts!

Another SMT stencil cutting post….

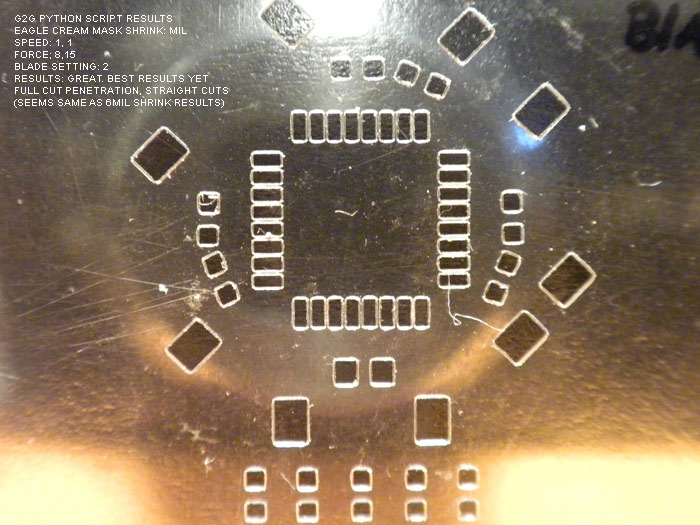

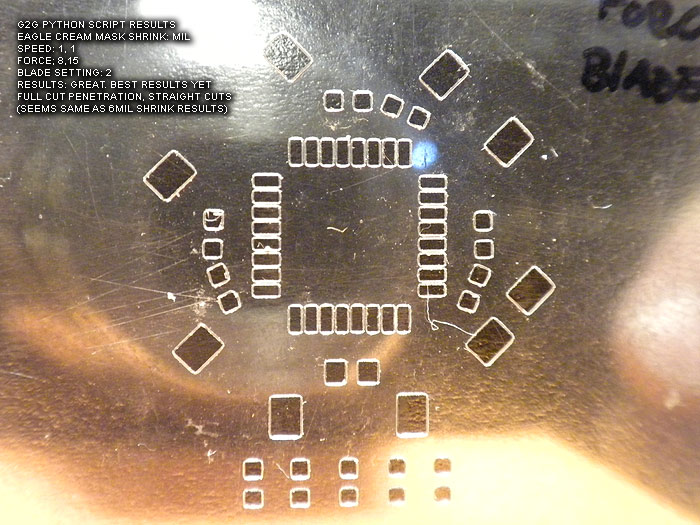

Finally some results! ![]()

I recently purchased a Silhouette Cameo (http://www.silhouetteamerica.com/?page=shop&cat=1)

Aside from all the things that can be done with this machine (cut fabric, vinyl, paper/card stock, etching plastic, cut cake fondant, stickers, signs, wedding cards/invitation, and the list goes on and on...) one of the things I wanted most was to be able to cut SMD/SMT stencils for making pcb's at home.

It has been a 'trend' lately, seeing the idea pop-up on HackADay , IdleLoop, DangerousPrototypes, and other blogs/forums.. so I decided to get to work on what it woudl take for me to produce the same results.

First I want to give a shout out and credit to several people/places as nothign I have done here is 'new' or innovative, its just the results from the hard work and sotware of other people, who decided to share with us, for this purpose. ![]()

HackAday, Idle Loop, DangerousPrototypes, Pmonta, teletypeguy, jessuscf...and everyone else I forgot.. ![]()

http://hackaday.com/2012/12/27/diy-smd-stencils-made-with-a-craft-cutter/

http://www.idleloop.com/robotics/cutter/

http://pmonta.com/blog/2012/12/25/smt-stencil-cutting/

http://dangerousprototypes.com/2013/05/17/cutting-stencil-using-a-silhouette-cameo/

(Im sure there are others.. but these were mains one..and they all link to each other or have a list of links in the articles themselves to oter relevant info)

With that out of the way..

the general overview of everything I have tested and read basically boils down to, there are only to 'viable' approaches that are worth the 'effort'.

Approach 1: Involves exporting a .dxf file directly from SoftCAD Eagle pcb design software, and you inturn import that .dxf file into the default Silhouette Studio software that comes with you Silhouette Cameo.

This is the approach outlined here at:

IDLE LOOP - http://www.idleloop.com/robotics/cutter/

by Cathy Saxton

The ULP script is located here on github: https://github.com/SWITCHSCIENCE/ssci-eagle-public/blob/master/cream-dxf.ulp

(not sure of the author..sorry)

* Dont forget to turn off "scale to fit" for DXF import in your Silhouette Studio preferences.

This is by far the EASIEST approach one can do/try... (its not much different than using your Cameo to open/cut any other .dxf file at this point.

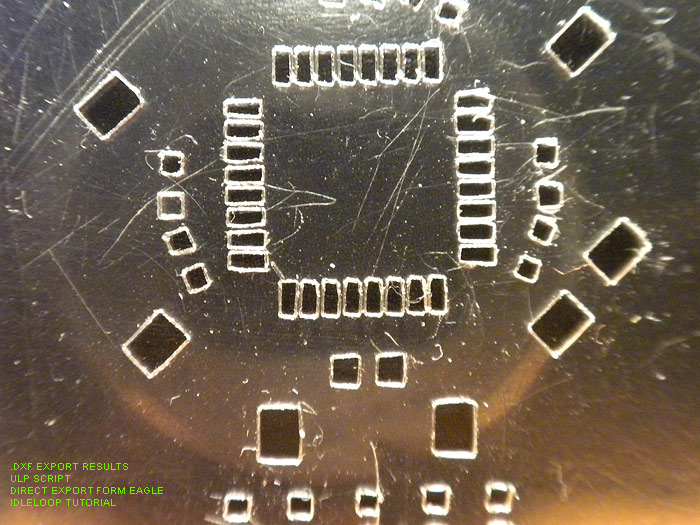

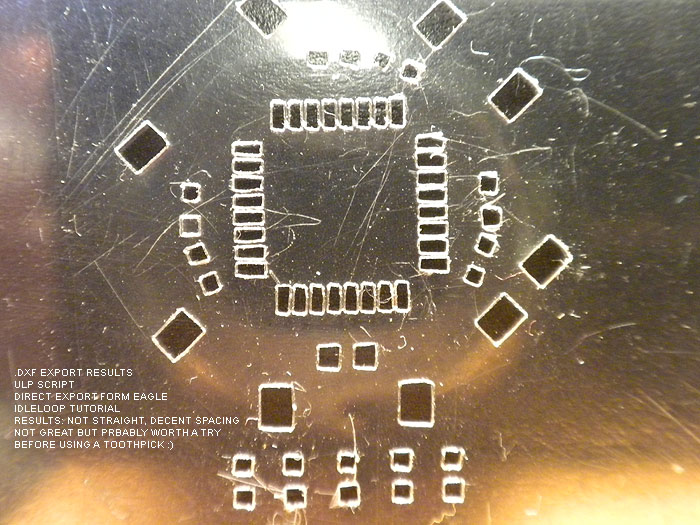

However.. the results were 'ok' (at best!).. and with soem tweaks 'usable' probably with some 'fixing' afterwards..

I experienced the same results as many others on the net have experienced..

not 'straight' cuts.. bowed out box lines, alignment problems..etc

Results: 'ok'.. probably 'usable', maybe with some fixin'/clean-up..

better than a toothpick and doing it by by hand I would imagine. ![]()

Next up is the GerberToGraphtec approach. This works DIRECTLY with the gerber file exported from your design software..

and is Python based...

This script/project is by: Peter Monta

http://pmonta.com/blog/2012/12/25/smt-stencil-cutting/

Github files: http://github.com/pmonta/gerber2graphtec

Being on Windows. this was a bit of a learning curve, and require the installation of several supporting apps.

(and not to mention I'm pretty much command line retarded)

Anyways.. download and install these app sin their default locations:

Python 2.7.5: http://www.python.org/

Gerbv 2.6.0: http://sourceforge.net/projects/gerbv/files/gerbv/gerbv-2.6.0/

pstoedit 3.61: http://www.pstoedit.net/

Ghostscript 9.07: http://www.ghostscript.com/download/gsdnld.html

As mentioned here: http://dangerousprototypes.com/forum/viewtopic.php?f=68&t=5341#p51495 in a post by: jesuscf..

he mentioned, for WINDOWS USERS.. we need to edit the gerbertographtec file.. (from what I have read it 'just works' for Linux and Mac.....figured I'd mention it to make you guys happy)

Download the .zip file and extract the folder inside...

Find the gerbertographtec file and edit it as follows:

1.) add the .py extension to the file name (to be able to run the program directly from a command prompt)

2.) Change these two lines:

os.system("gerbv --export=pdf --output=%s --border=0 %s" % (temp_pdf,input_filename))

os.system("pstoedit -f pic %s %s 2>/dev/null" % (temp_pdf,temp_pic))

to:

os.system("\"C:/Program Files (x86)/gerbv-2.6.0/bin/gerbv\" --export=pdf --output=%s --border=0 %s" % (temp_pdf,input_filename))

os.system("\"C:/Program Files/pstoedit/pstoedit\" -q -f pic %s %s" % (temp_pdf,temp_pic))

*He mentions this is because some of the apps above (gerbv & pstoedit) added their executable folders to the path.

One of the final steps is 'sharing' out your Silhouette Cameo printer, in the Printers & Faxes screen in the Control Panel.

(right click >> sharing & security >> share this printer (name it: Cameo)

At this point, I had some problems with the command line stuff he was posting to use to initiate the process and start cutting:

C:\gerber2graphtec-master>gerber2graphtec.py test.gbr > result.txt

C:\gerber2graphtec-master>copy /B result.txt \\[YOUR COMPUTER NAME]\Cameo

alternate line to use: (not tested)

C:\gerber2graphtec-master>gerber2graphtec.py test.gbr > \\[YOUR COMPUTER NAME]\Cameo

I had tested things as described and kept getting error after error.. (not sure if it was a pathing problem, or installation problem on certain supporting apps)

either way.. I ended up just using a .bat file another member (teletypeguy) posted, and uing the same file structure.

that ended up being this:

on _root of C: drive:

Create a folder called: gerber-files-to-cut

ie: C:\gerber-files-to-cut

INSIDE this directory, you put/copy the gerbertographtec folder you downloaded at the github link above (dont forget to edit it as outlined above)

ie: C:\gerber-files-to-cut\gerber2graphtec

and the .bat file I created/used was this: (use your computer name, not [computer_name]

@echo off

rem This is for printer named "Cameo" which must be named and shared in control panel.

rem This is for computer named "hacker"

echo.

echo This script will send gerber file to Cameo for cutting solder stencil.

echo Generates intermediate files .pdf, .pic, and .graphtec.txt

echo.

echo Set your Cameo blade to 1 and turn cutter on.

echo Load mylar sheet (landscape) at upper-left corner of mat.

echo.

set /p filename= Enter filename of gerber (eg: test.spt or board.gbr):

gerber2graphtec\gerber2graphtec.py %filename% > %filename%.graphtec.txt

copy /B %filename%.graphtec.txt \\[computer_name]\Cameo

This .bat file should be INSIDE of the: ie: C:\gerber-files-to-cut directory.

At this point.. you are ready to startm aking test cuts.

Be warned, this a VERY SLOW process, but very accurate and te results are pretty good.

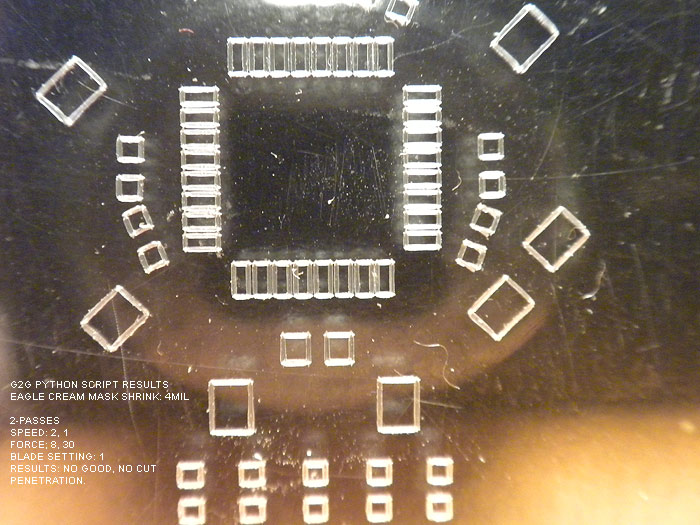

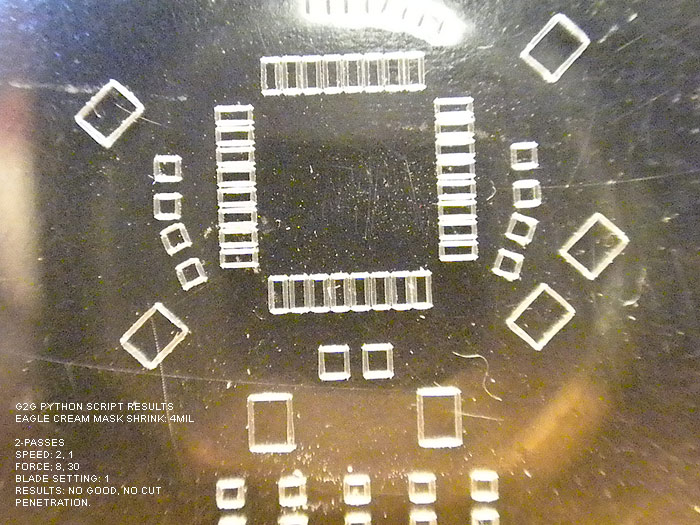

2-passes, pretty much 'stock' configuration

did NOT cut all the way through!!!.. but looked good (pic doesnt really do it justice as the shadow and it didnt cut all the way through making it look 'fuzzy/choppy'.

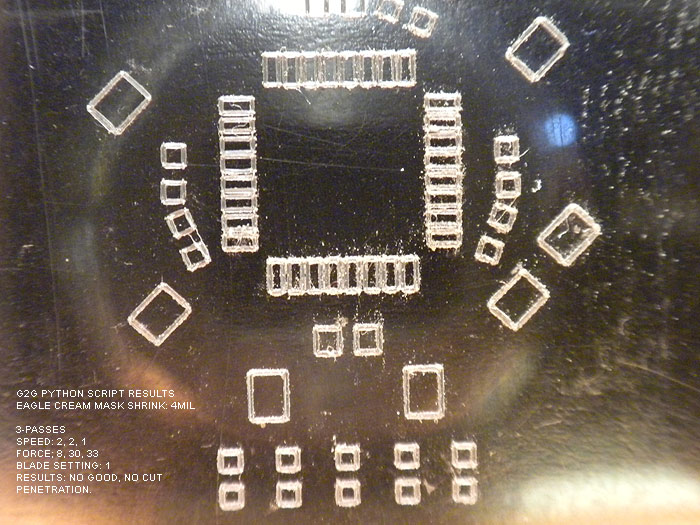

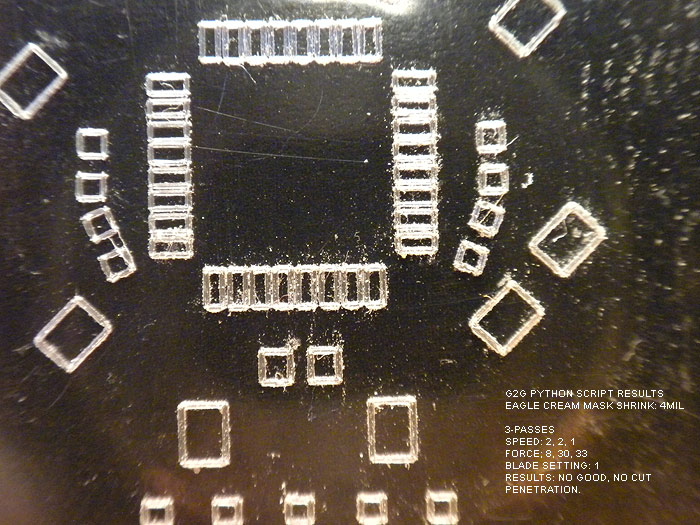

Edited to 3-passes

result: still couldnt get the cut to penetrate..(backside was still smooth)

ok.. so at this point.. Im thinking: "Geez, the ULP script and .dxf export from IDLE LOOP looks great right about now!" LOL..

no matter what a BLADE SETTING of 1 wont cut it!.. and the holes never were cut out.

blade setting of two was too much and ripped pads!

but I kept reading around and asking questions, and was informed about the defaults in the gerbertographtec.py script..

(about how to add more than 1, 2, 3 cuts, and the force (pressure) parameter as well!)

This,.. in addition to the tip on shrinking the CREAM layer in the DRC >> MASKS tab, seemed to charge new life into me!

So I opened the gerbertographtec.py script (I also learned you can add these parameter to the batch script, but I think I was more comfortable editing the .py script itself, and commenting out other 'settings' for later review/use

found these lines/values:

offset = (4,0.5)

border = (1,1)

matrix = (1,0,0,1)

speed = [2,2]

force = [8,30]

cut_mode = 0

and edited them...

the only one I really messed with was speed & force (although by default the script will cut a 1" board around your pcb largest area.. you can change this in the border default)

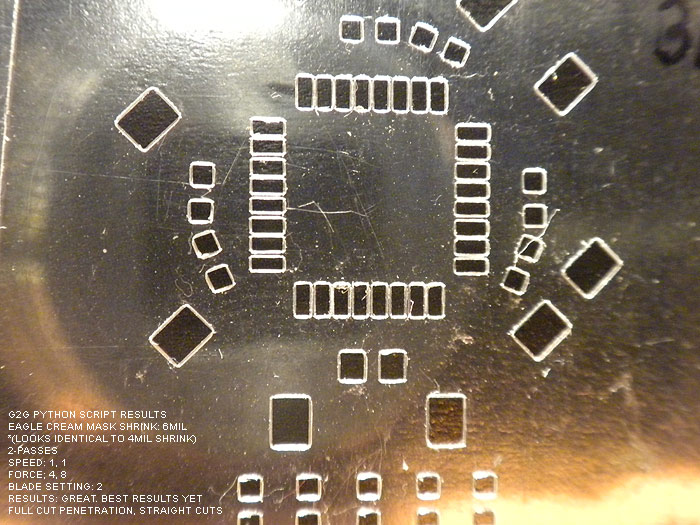

(all images should have the settings used and the results in the image)

Also note that I tried to shrink the CREAM LAYER in Eagle before exporting by 6mil.. and it looked/showed no different than when it was at 4mil.... not sure if it is due to the iTeadStudio CAM file I used to export the gerber files or what?

either way Im happy and impressed with the result so far:

keeping the blade setting at 2..I tried different runs, speeds, and pressure..

here are the results:

At this point. I believe these to not only be usable.. but of 'decent' quality.. (better than the laser ones I have 'paid for perhaps?)...

I am going to be trying the Apollo write-on transparency sheets from the local Home Depot this weekend.

*Project note:

I still get an error/warning every time I run this...

"The procedure entry point ?construct@?$allocator@VVPath@Magik@@@std@@QAEXPAVVPath@Magik@@$$QAV34@@Z could not be located in the dynamic CORE_RL_Magik++.dll"

*****update: by removing the .dll from the directory, this solves the error..

it has to due with either gerbv or pstoedit (I cant re-call off hand).. however I have even tried installing Image_Magik..to get the .dll's and copy/paste them to the directory.. (error persisted)

Love to hear what anyone has on this error and how to fix it!

thanks to all the hardwork and posts of everyone before me and where I source the info/help from!..

its a great 'tool' to have, and a nice ability to not have to source/pay for solder paste stencils any more for hobby/protype work!

update:

at the Dangerous Prototypes forums.. there have been additions done by the members..

* a new .py script hat is optimized for not only faster speed.. but seems to perform better/straighter cuts through the entire stencil/area

* a new GUI for editing the parameters and fine tunign control as been created as well

* Linux and MAC support for the GUI...

IMHO.. this was worth the purchase of my Silhouette Cameo alone.. ![]()

thanks!

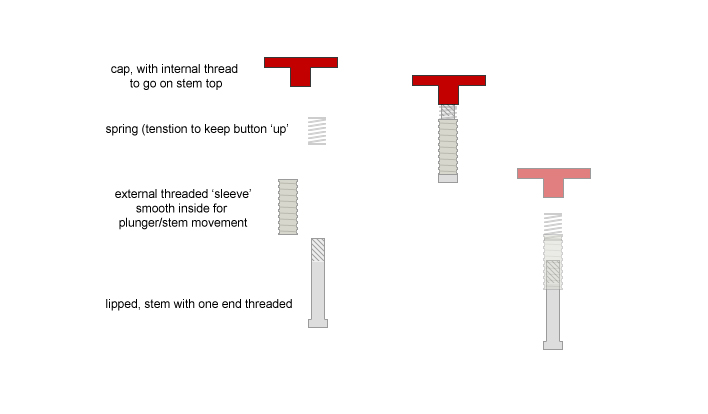

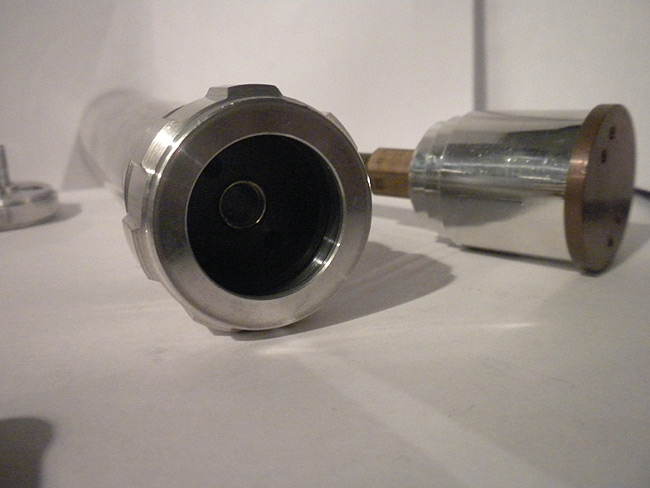

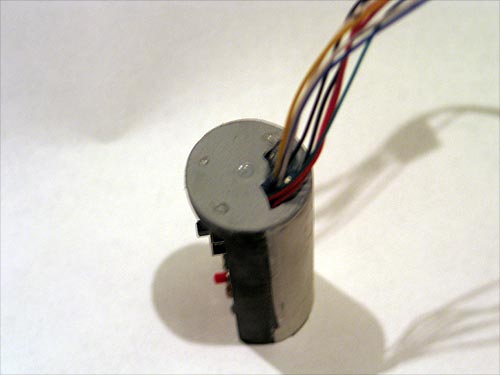

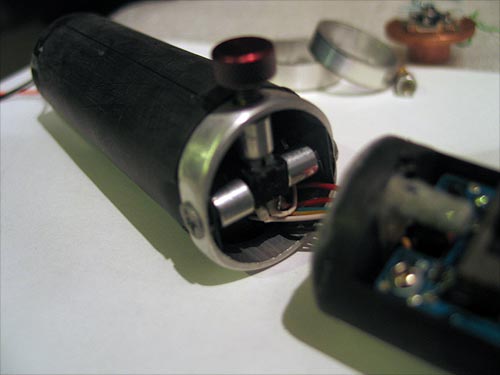

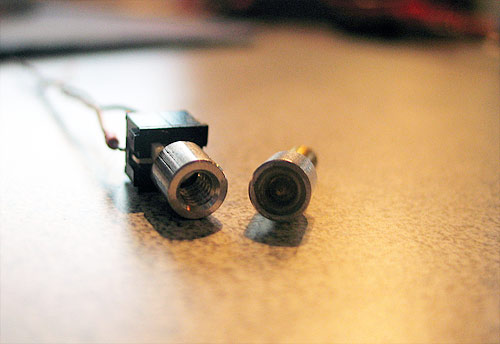

PoC: Plunger Switch Prototype

I never posted these... and just recently remembered about them when reading Ace's Obi TPM run thread.

I posted on them..(did a quick sketch while at work to help explain it).. to maybe offer help.. (but no one even acknowledged I posted... boo hoo.. poor me.. right?!) ![]()

![]() lmao!

lmao!

Erv drove into me 'document everything'.. (so here I am.. maybe it'll help fix a cram-fu problem!)

anyways.

I worked on a few different ideas of 'mechanical' switches or methods to trigger latching/momentary switches when I got those illuminated switches a while back..and then again when I started working on 'cores' and all components secure to it (ie: Easterns x-mas gift/x-core..integrated switch)

(Im sure you've seen a few here and there..but I dont think these plunger style ones ever)..

I suppose it depends on your specific application/project but (again) the idea is sound/stable..

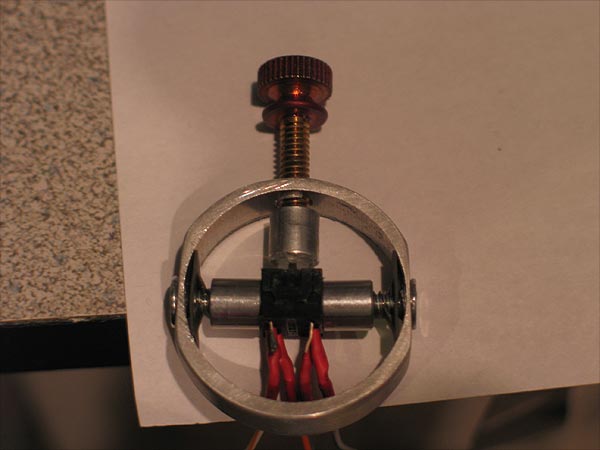

yanking the pic I made in Ace's Obi run thread..

for myself,.. these were to serve several purposes.. solvable by either changing the length of the outer threaded sleeve, the length of the 'plunger'...or both. =)

a shorter length threaded outer sleeve lets you thread directly into the hilt...(for switches that are very close to the top of the hilt)

a longer length threaded outer sleeve lets me thread into the hilt..but ALSO my core (or delrin disk..etc)

when I do this..I need a longer plunger end as the switch is usually set deeper and not at the top by hilt/hole.

these are all garage/hacked, home machined..etc Im sure if Ace tackled this, they would turn out much nicer,,and the fit and finish of course would be top notch. (even maybe a lip or something to stop screwing all the way in)

only con I have found so far is its a bit difficult to screw in the threaded sleeve sometimes.. (you need to tape up some needle nose pliers and get to turnin'!) lol

(this is actually how I am planning on finishing my own personal Obi hilt using the bike vale and red button as my switches) (one of these days, right?) ![]()

![]()

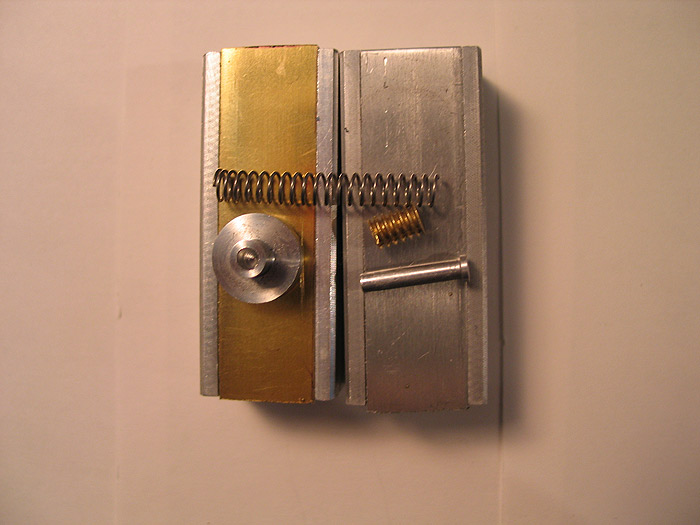

ok just so there is some Proof in the puddin',..another proof of concept..(PoC)

some pics:

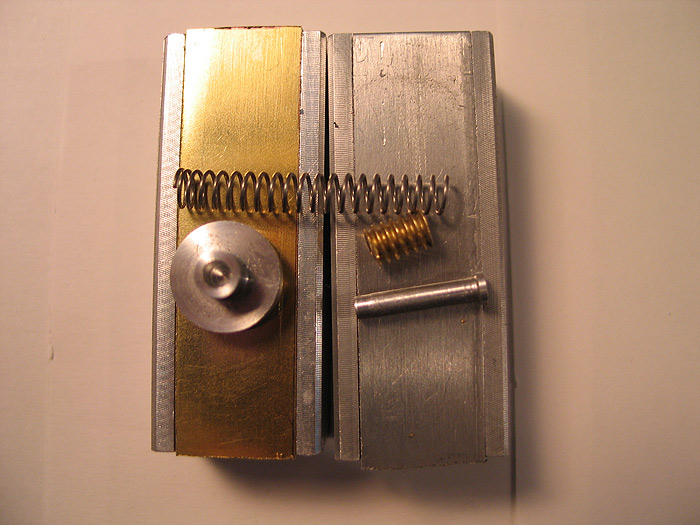

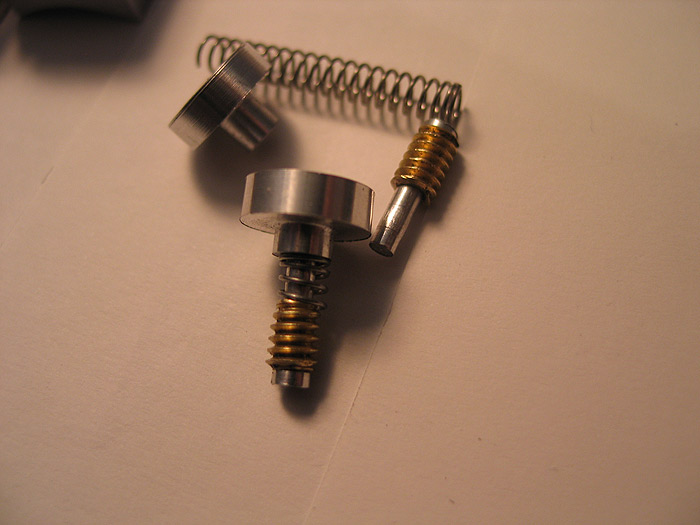

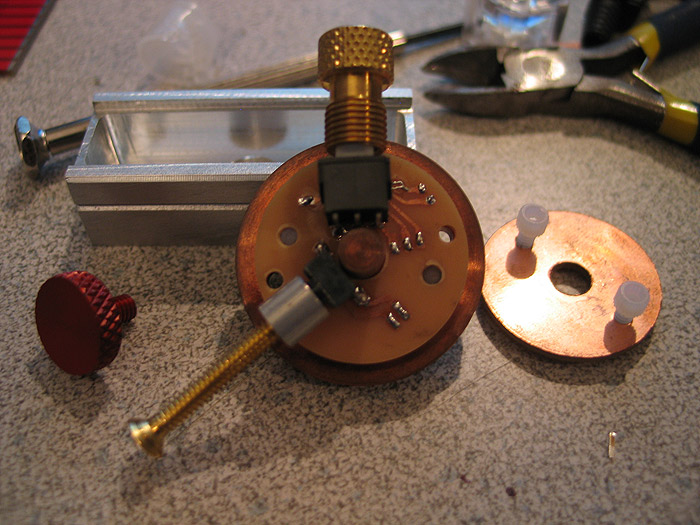

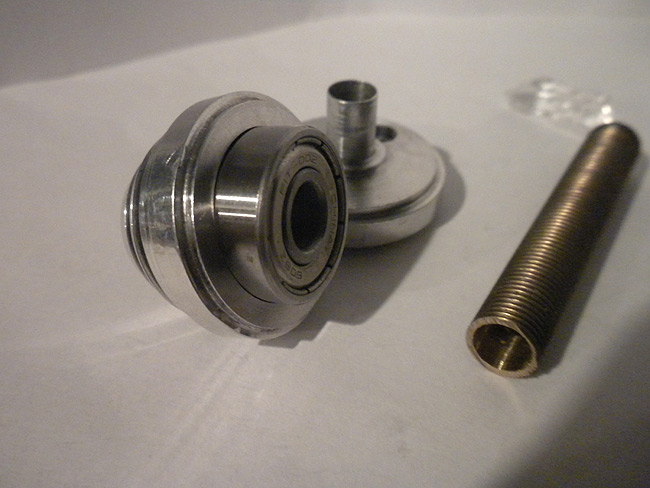

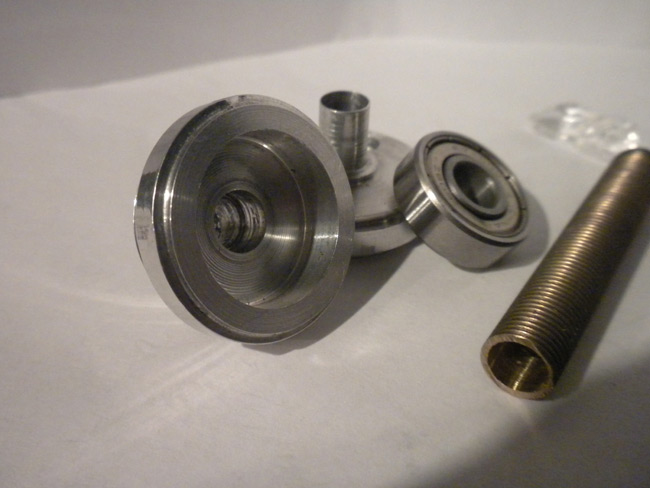

part(s) breakdown:

(on top of some TCSS boxes..with some brass and aluminum strips I cut out..same thickness..they turned out good..need to sand edges..and buff)

this is NOT fully screwed in.. but it is also a longer sleeve version.. cut the sleeve in half..

and you can even counter sink/bore the switch end to get it lower/closer to the hilt if you wanted.

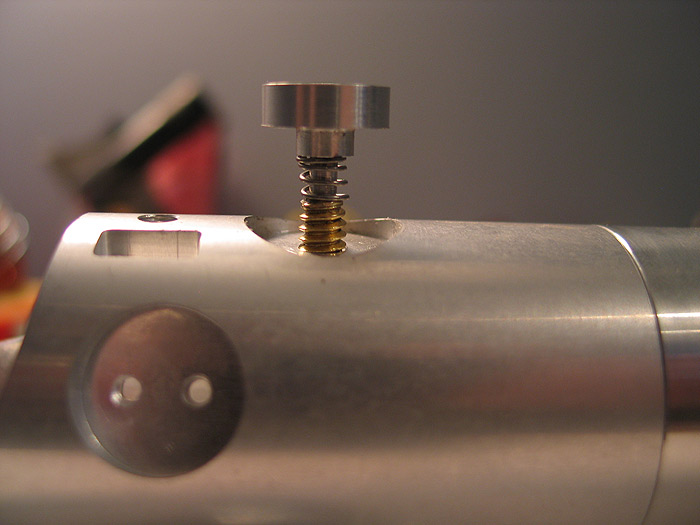

see how it works/side view:

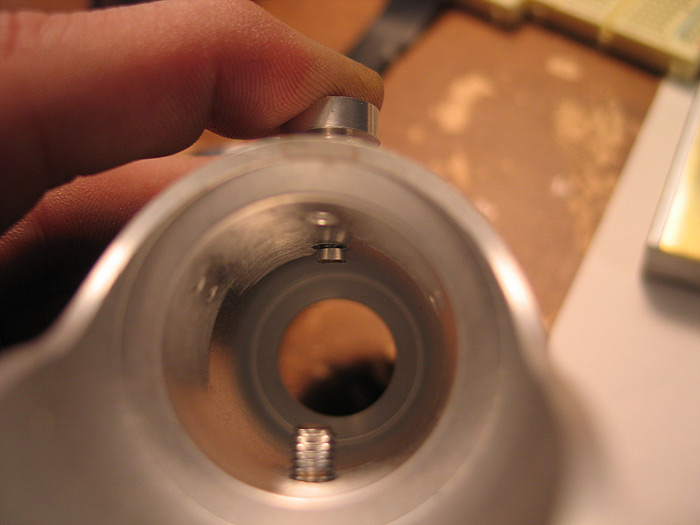

shorter plunger see how it goes into hilt to trigger your switch.. of course these are changeable to any length to fit the depth needed.

and not-engaged:

I have two more that are going to go on top of one of these control box.so the switches are on top of the 'cover' and spring like this.

anyways..hope 'someone' enjoys them.. LOL

thanks

PoC: Custom MHS heatsink pcb (for my Obi TPM)

was going to post this in the 'idea thread'.. but figured just make its own thread for it..

another step in my OBI TPM saga.. lol

trying to keep the size as accurate as 'I' can, and still having it be somewhat MHS based at the core...

I was stuck on finding out a way to use the stock switches as real, functioning switches for my hilt.

(Ive always been keen on the all-in-one core ideas... but have the switches on/in the core and some sort of cap/plunger on the outside has always been a PITA for me... here and there a few ideas have came out/been used)

for the OBI.. when everything was done,.. the switch holes would go (more or less) at the same exact level of the MHS heatsink.. so I need to adjust that a bit.. and also find a way to mount some switches in that area..

I had mulled over Madcows switch approach. but just wasnt a good fit..

so I came up with a custom, round PCB, that mounts to the underside of the heatsink..and is secured using the same nylon screws that hold our luxeon star pcbs. (MHS hack!)

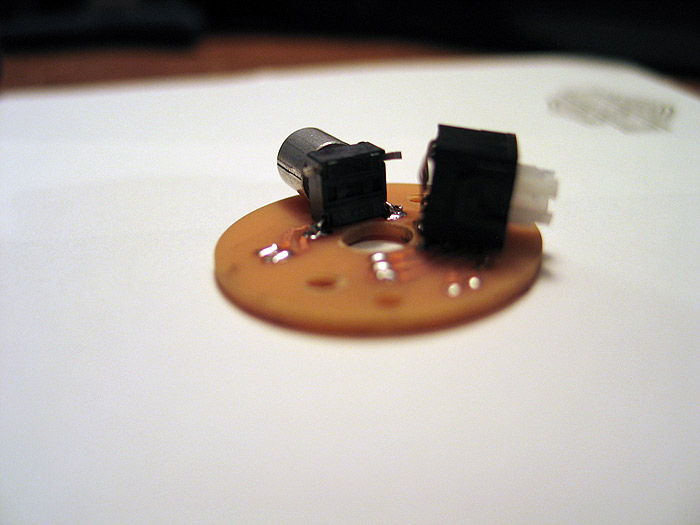

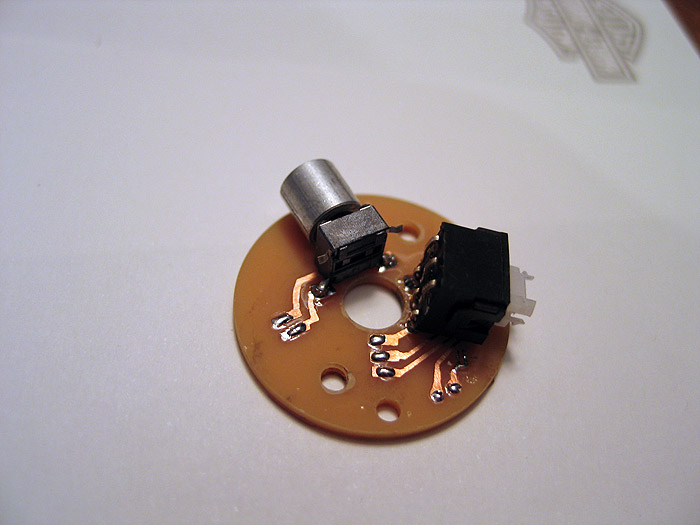

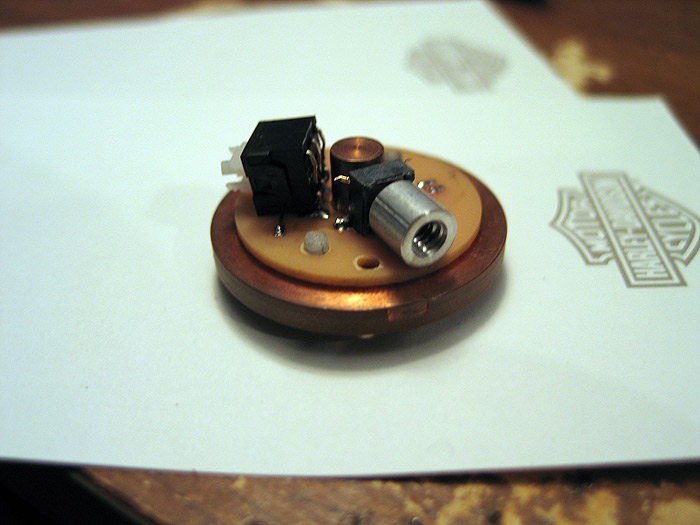

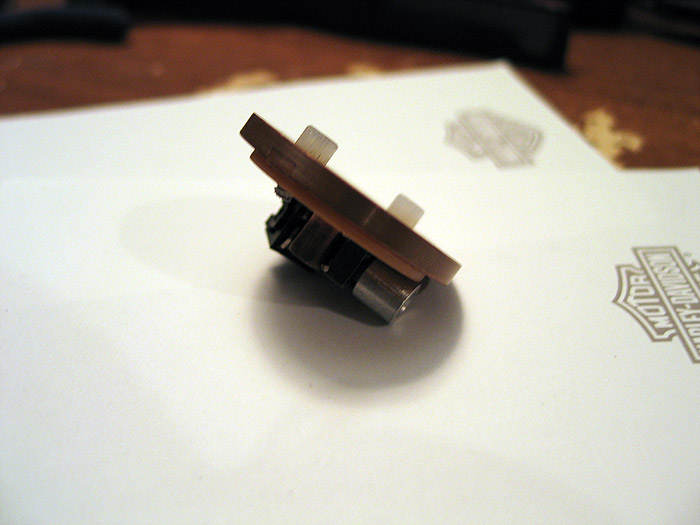

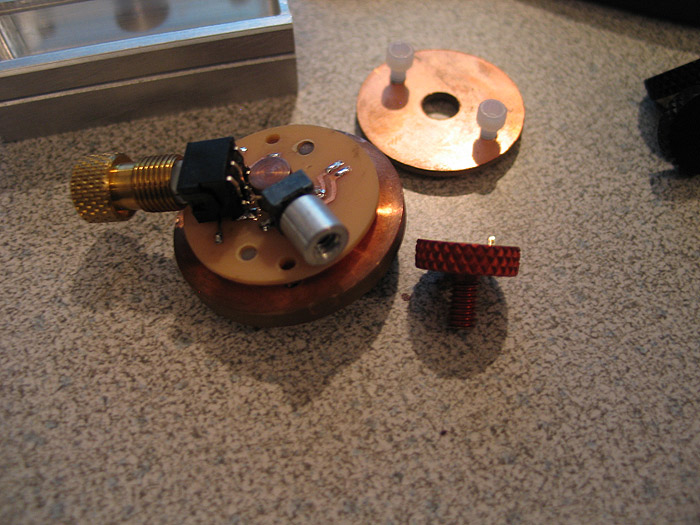

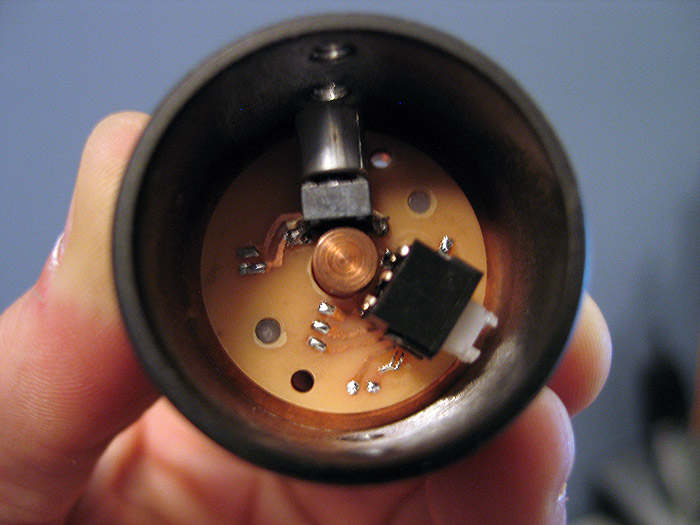

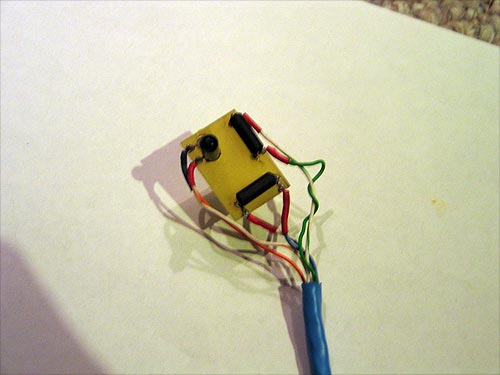

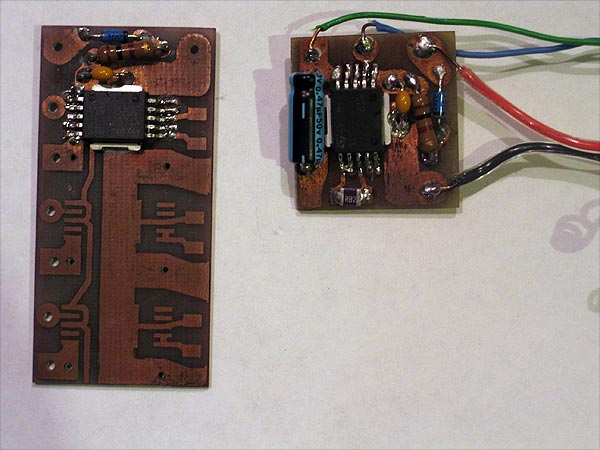

here is my prototype..

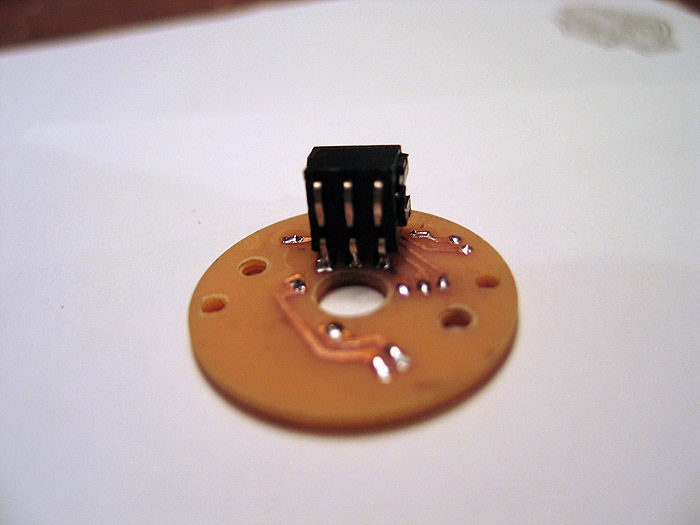

the bike valve switch will have an SMD led in it.. (like they normally do).. to light up the purple gem in the valve end. I just didnt put it back in yet..from doing the momentary mod to the switch (latching by default)

I also didnt clip the extra leads from the switches yet.. but I believe the idea is sound.. and can open up the doors for others to use the same idea/approach.. (nned to mount a unique switch?.. make a pcb for it!)

I posted a tut on how to etch your own pcbs..etc.. using your home laser printer and photopaper..

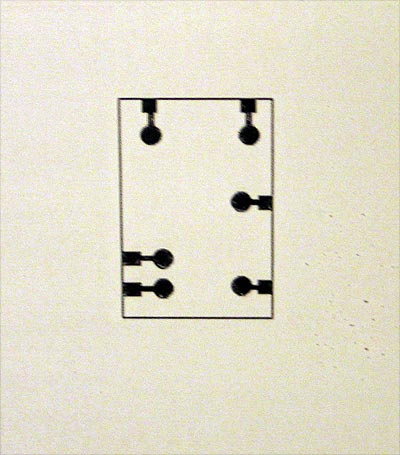

1.) make pcb deisgn in photoshop..

2.) print to photo paper

3.) iron to your copper clad board.

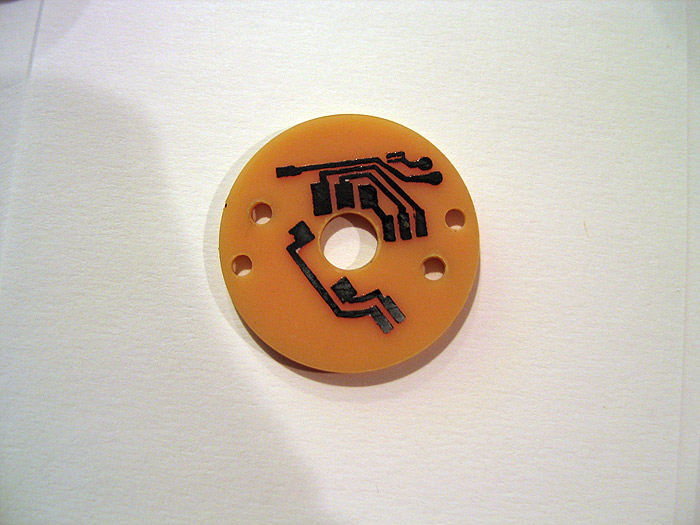

you get this:

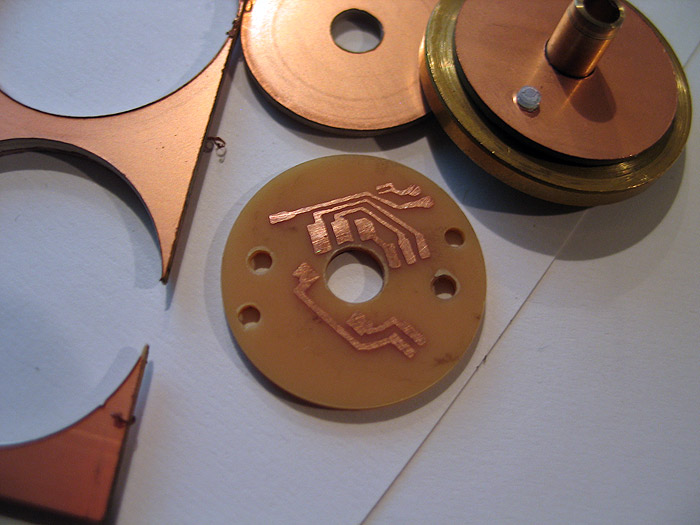

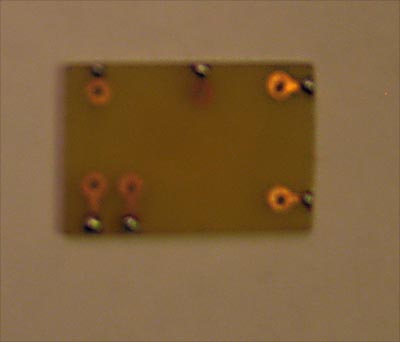

etch and you are left with your laser printer traces (covering the copper underneath)

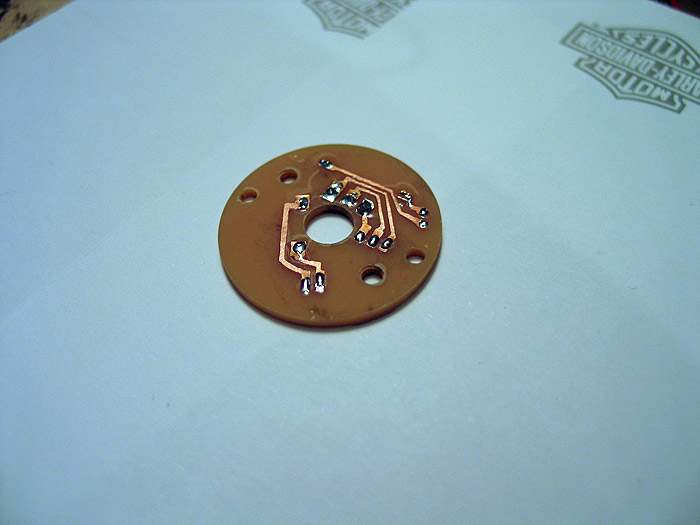

remove toner: (pcb is left)

Like Erv taught us.. pre-tin folks!

bend my switch leads underneath..and the other row down:

other switch:

on heatsink:

I dont have a red thumbscrew with the correct threads yet.. but you can see it mocked up there.. (screws right in from outside of hilt)

when heatsink is in MHS part.. it lines up with the holes perfectly.. (cant see it so good in pic_ =(

feedback always welcome..

hope this helps others get past road blocks in their projects!

thanks

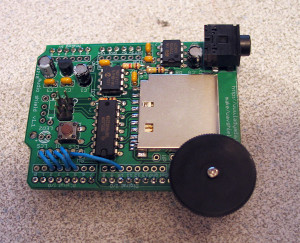

Arduino: WaveShiled build process

Hey gang-

while I was working on my own custom Arduino based project.. I found myself without a real way to compare the audio output (volume/quality) against the Adafruit WaveShield which I based my project off of)

So I was about to order one.. when I found a guy at my local makerspace that actually had one of these kits. The catch was he had never put it together.

So the barter was on.. I can borrow and test it.. as long as I put it together for him.. (pfft.. no problem!)

Here is my documentation of building an Adafruit WaveShield..

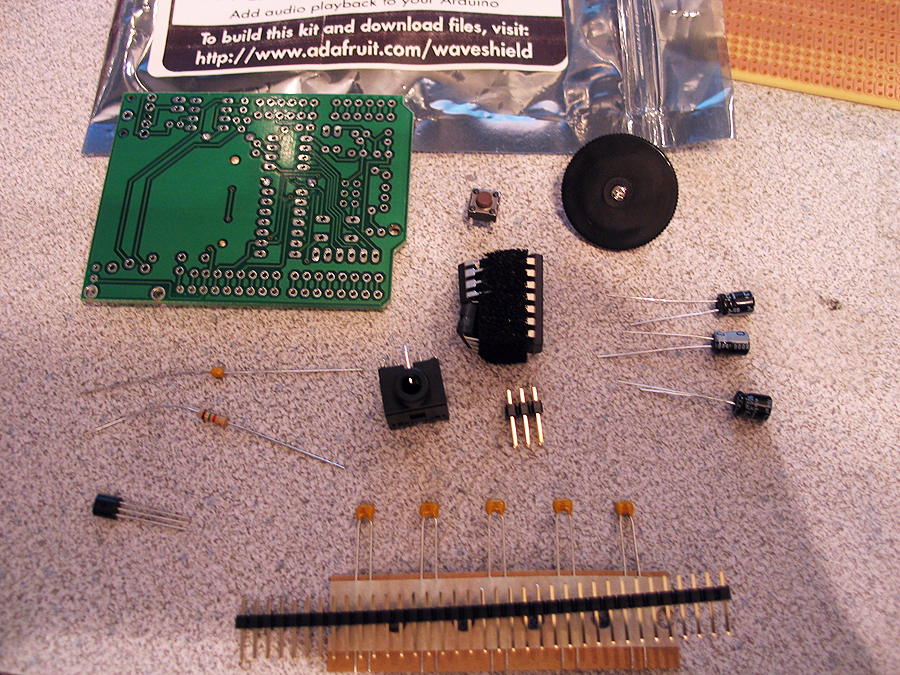

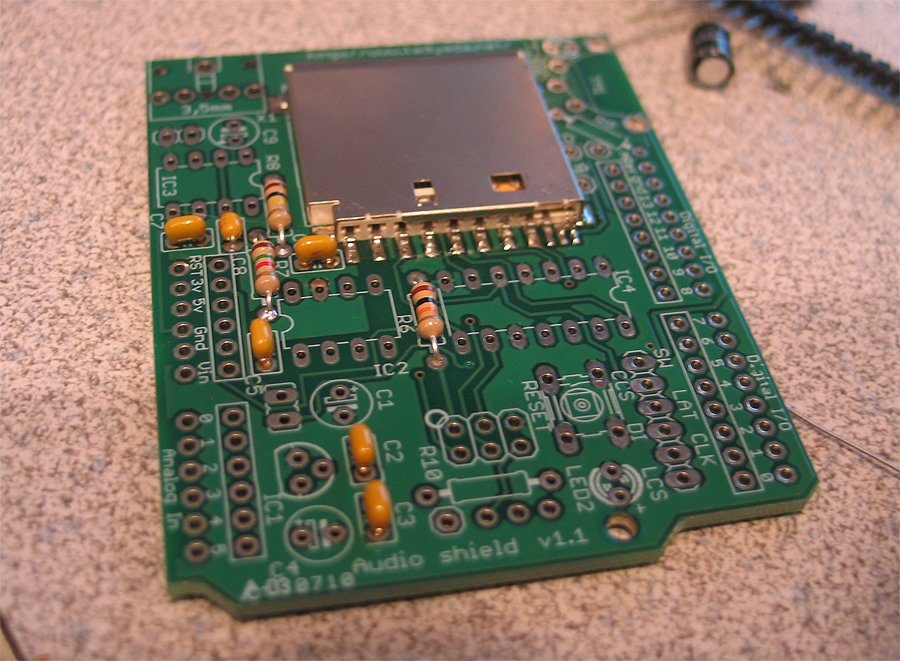

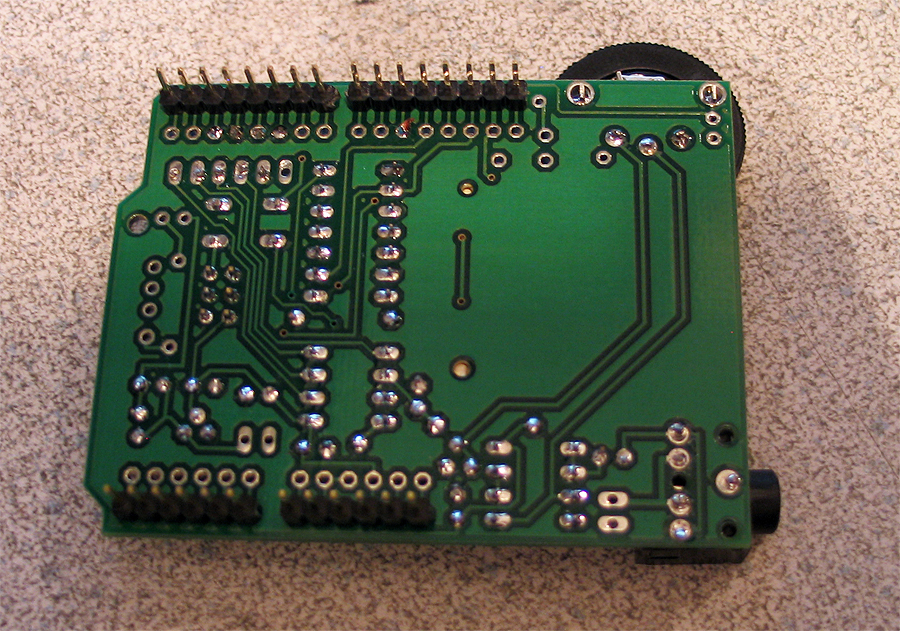

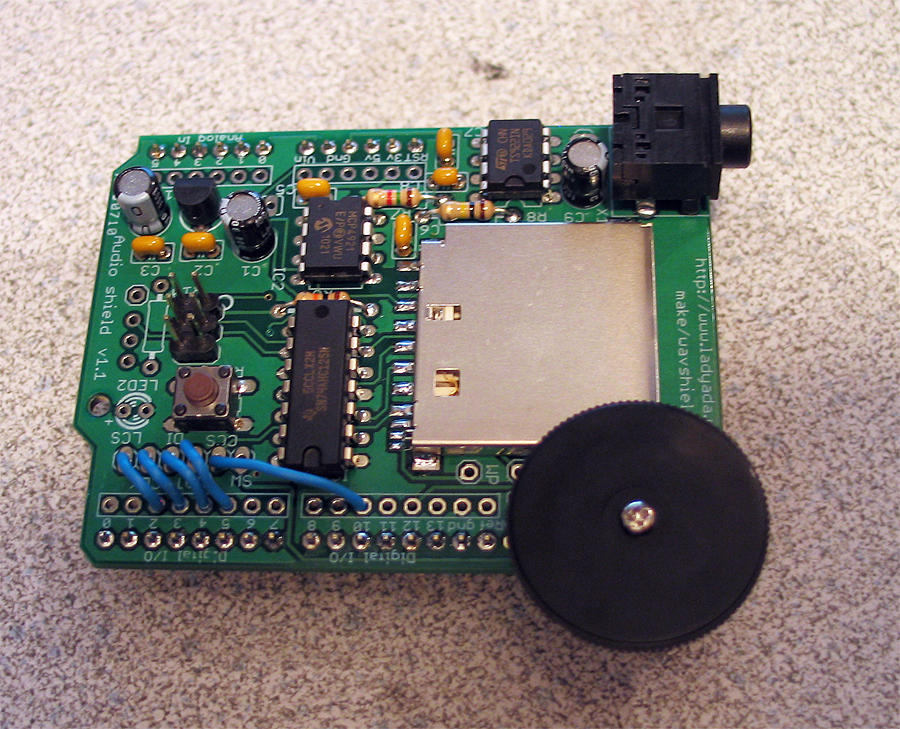

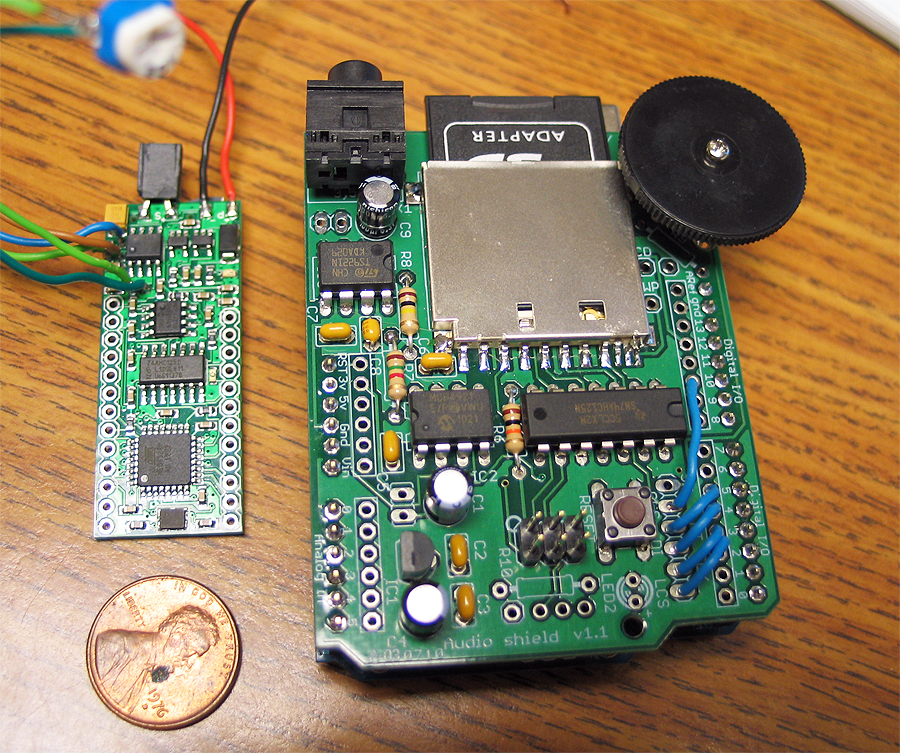

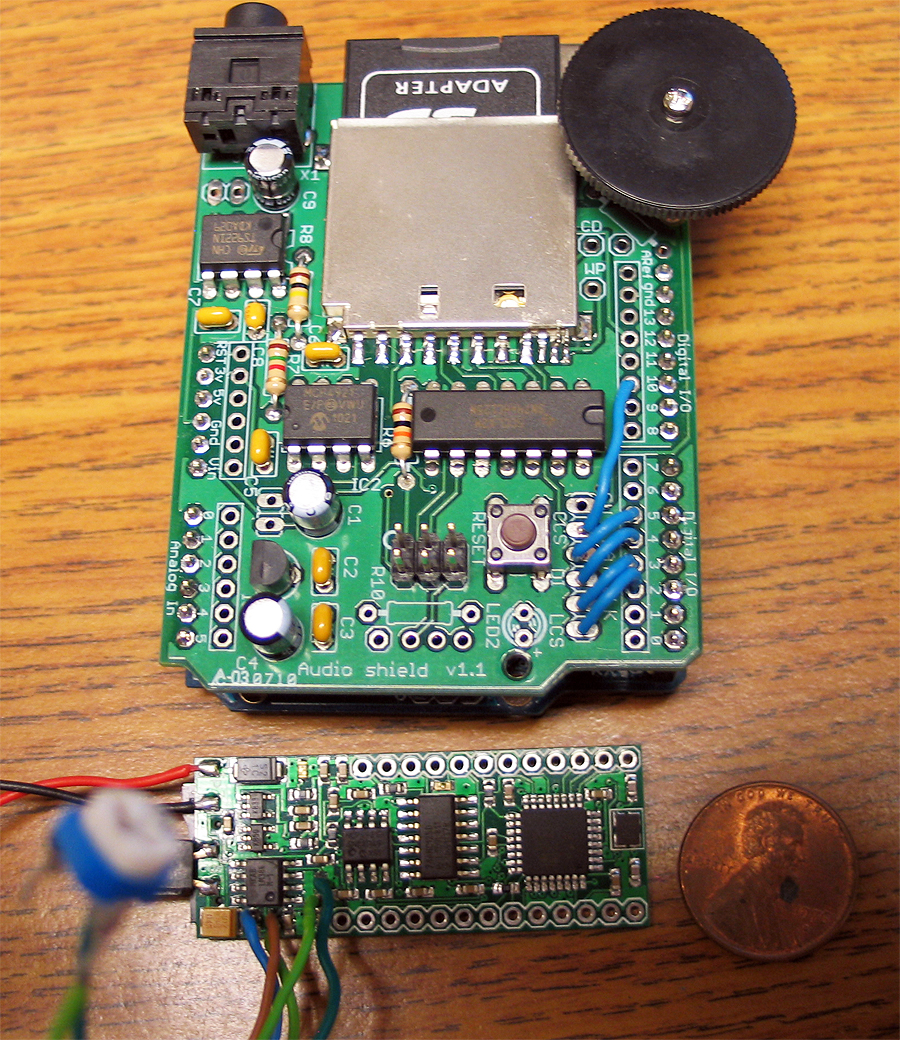

the kit parts:

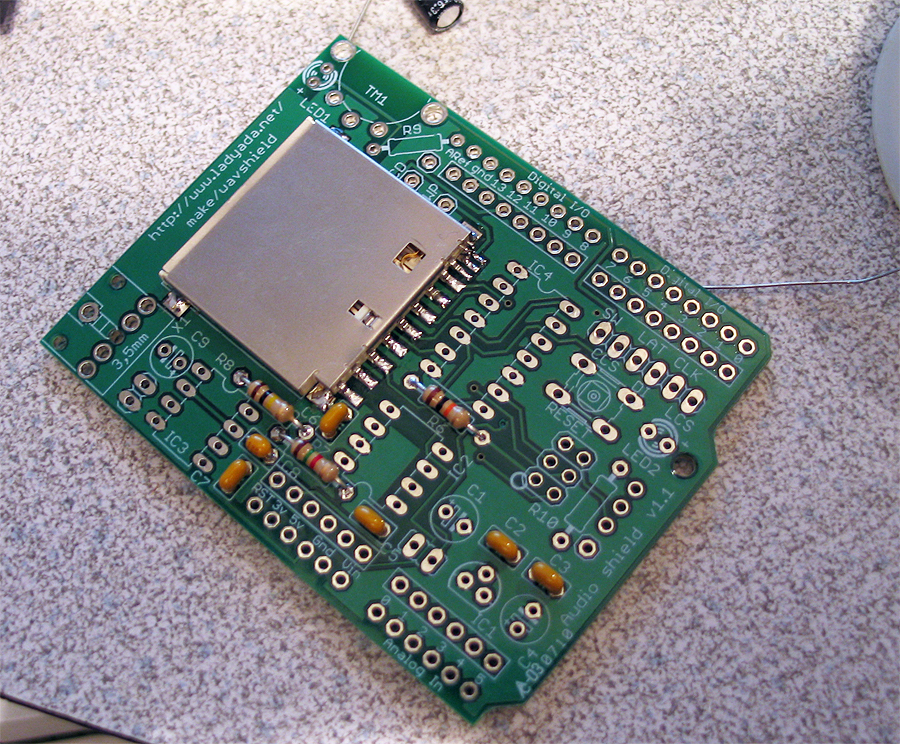

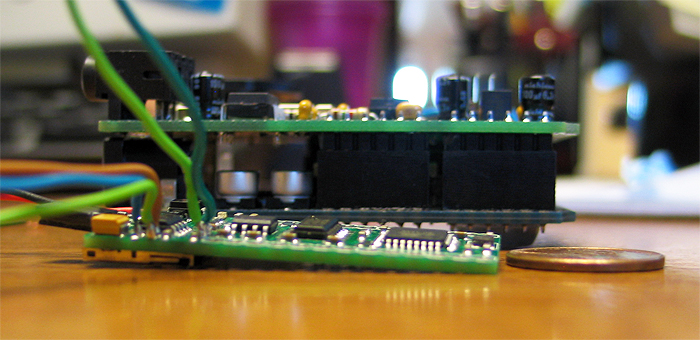

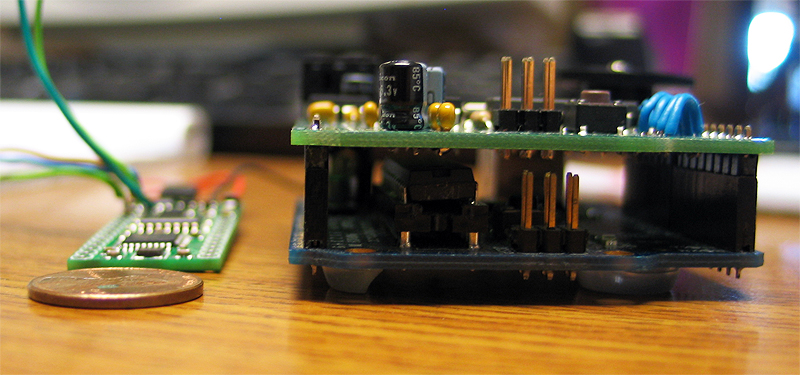

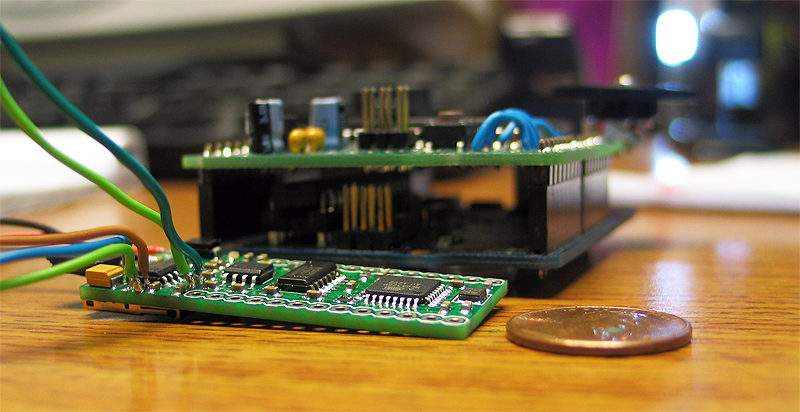

compare shots against my custom board, for size:

thanks for looking!

summary: nice and easy kit

does what it says in minimal time and effort

volume quality is 'not' that great.. (but they know about it.. and they provide a resistor hack for adjusting the volume)

the filter/range is a bit muffled too..

over-all its better than straight, un-filterd, un-amplified PWM audio! and its only around $20.00

PS.

special thanks to Pete P. @ the local Milwaukee Maker Space! (you guys rock!)

R&D: Proof of Concept bearing chassis/core mounts

Being as its winter here..and I doubt I'll get in the garage much, anytime soon..

Wanted to post this idea/concept I had in my head..

while the pics are of a 'core/tube' type chassis this same concept could be used to an open 'sled' type chassis as well.

I talked about this with Fender a bit as well.. although the reverse sound one is not 'pictured'..

I think the idea is sound.. and this is just a roughed out idea..(including the cuts!!) ![]()

Im sure someone can tweak/fine tune.. find a better way. (in theory, a bearing wouldnt even need to be used..but makes it smoother)

Pros:

nice way to secure your core/chassis to your pommel for easy removal

no twisting wire problems

Cons:

mod'ing the speaker holder is PITA.. because the stock speaker OD is big.. I ruined s peaker mounted.. and that one pictured 'was ruined' but salvaged..lmao

in certain pommels, it wont work. (to close to end for insert)

not a lot of resonance

Together view: (not in pommel...but a possible end result could be)

Here is I have my 'core' (main tube) that can hold soundboard & batteries.. the top portion is just added from another past project.. (but is one possibility)..

that top part also have a bearing in it.. and can 'spin'

The 'main' part..(together)

The main part(s) (what is consists of)

turned 'stem' to fit bearing.. (can see similar in background)

Bearing got on stem..

I cut a piece of some external threaded tubing I had NPT 27 tpi I think?.. hollow..

that is actually press fit on there..and is not coming off.. but could be glued just as well little dab only..

it helps keep the bearing in/down... and the threaded part is used to secure the back of the MHS speaker mount.. (NPT 27 tpi tap...I'll have to look up exact size off hand)

the MHS speaker mount is turned to OD that fits INSIDE the pommel ID...easier to just bore out the pommel a bit though to be honest..save your speaker mounts from being wasted..lol.. hard to leave a 'wall' to snap the speaker into

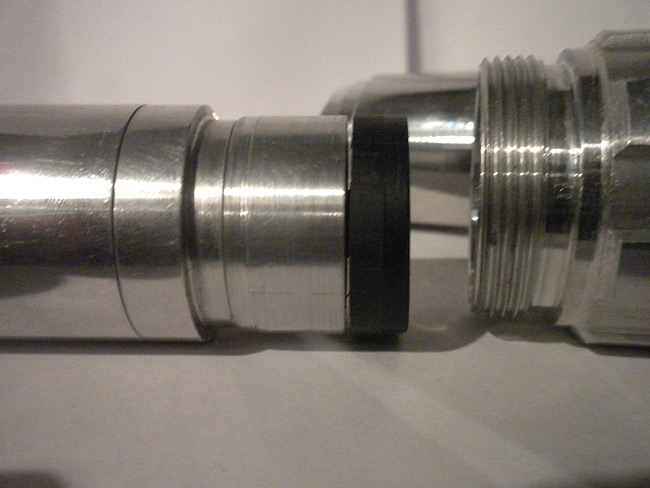

there is a 'ring' with the ID of the bearing OD.. and the OD of a pommel ID

this slides over everything (stem, bearing, NPT secured threaded end)..and has hole tapped so set screw locks ring to bearing..

now you have your free spinning 'ring' that the pommel makes contact with..leaving the speaker/mount secure/non-moving

you get this:

the speaker side.. (see how its threaded through)... maybe dab of glue too?

alternate pommel (still works)

off-topic:

Here is the top portion.. (although a bit off topic)..notice similar 'stem/bearing' system..

but this time a top part goes over the bearing.. (set screw secured to bearing)..

and it spins the crystal, etc..

back on topic:

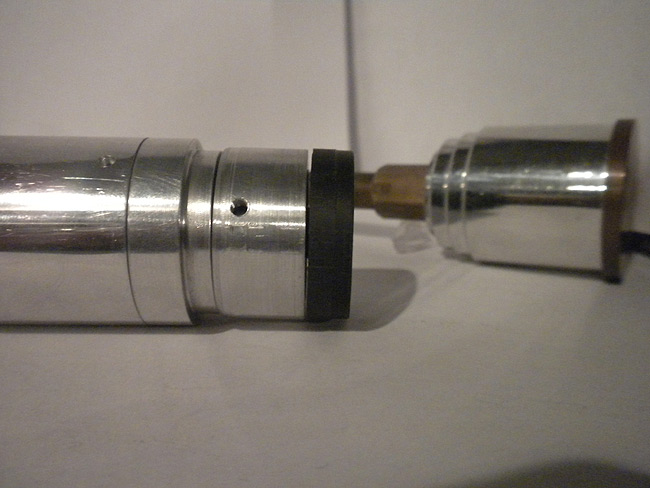

ok..so you take the whole thing..after you secure the 'bearing mount' to your core or chassis...etc..

and it slides into your pommel.

you can see the little drilled & tapped hole in the pommel.. un-obtrusive.. and it secure the pommel to the 'core'..make sure you secure it to the 'free spinning ring'.. and not the speaker mount..

side view:

feed back always appreciated,..

Im sure it can be improved upon...so thats why I shared it..LOL

maybe not for every build..but if the case calls for it..here is one solution to apply.

Thanks

DIY: Homebrew PCB etching

Not sure how many (if any) of you may ever need to do this...

but if you want to mount those sensors we got or accent leds..(or anything) to a little custom PCB for your projects..

you can make a PCB all by yourself with nothing more than a black-n-white laser printer, the copper pcb board, and some etchant solution

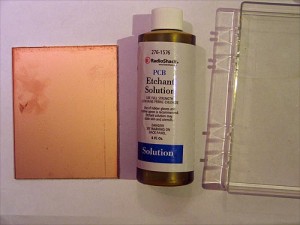

Etchant Solution:

http://www.radioshack.com/product/index ... Id=2102868

I think they stopped making them..but some stores still have old inventory.. (I got my last 2 kits for $3+ each)

# 276-1576 is the KIT# (read the description, and you'll see reference to the kit)

comes with:

etchant solution

tray(s)

etchant/ink remover solution

copper PCB board (2 thicknesses)

drill bit

scotch brite pad

permanent ink marker

you really only need the etchant and the copper pcb board.

I made a little layout/schematic (nothing special)

in photoshop.. @ 300 DPI

** make sure you print on glossy PHOTOPAPER.. this works best in my tests..

print out your schematic..

cut out schematic

iron schematic to the copper pcb board... let it sit a bit.. make sure transfer is nice.

under cold water.. 'wash away' the photo paper on the PCB board.. it will leave behind the INK/TONER from the paper on the PCB..

(I didnt take a pic of this....sorry)

but it would be like you printed ON the PCB (more or less) after you wash away the photo paper with water.

fill tray up with etchant solution..

throw section of pcb board with print out ironed on it..into tray..

(etchant will eat away/remove ALL copper 'except' where the ink/toner was left at)

once all copper is gone..and only black ink/toner is left on board...

you can take high grit sand paper or the scotch brite pad..and clean off the toner that was left on the board.. revealing the copper (now traces) on the board..

It can be used to get some fairly decent lines and things are very crisp for what it is..

I made a 'pcb' board to hold my X & Y axis swing sensors....and my clash sensor.. and soldered solid core wires that fit into my bread board to test with the RFX project..

Ive also used this method to make a few LED driver boards to drive a LUXIII/P4 w/PWM support... as well as a 3 & 4 driver board for RGB or RGBA diode LEDS..

I made these printing on WAX paper though..and the transfer isnt as good after ironing as using glossy photo paper and washing it away under water after ironing.

and these are just HOME BODY, DIY needs..and they work a treat..

image how small things could be if they were professional designed and manufactured!! PHOOK!>.lol

hope this helps any of the DIY builders out there..:)

-----------------------------------------------------------------------------------------

For these tests...

I have used a very affordable HP LaserJet 1022n (n = networked)/

basic stock black-n-white laser printer.

as for photo paper.. I have success with several brands, sizes & type.. glossy or semi-gloss all types were..

all transfer CLEAN, SOLID lines..vs. using a wax paper or a mailing label backing or similar..

I was very impressed with the quality of transfer using photo paper vs. anything else.

re: etchant.. a few other things to note..

myself. (wrong or right).. I keep my solution in a plastic tub/container.. (with lid)..and just leave it.).. I re-use it.. sometimes adding more or etchant at times..

also adding air/bubbles to the solution helps speed up the process and works well...

my point/goal was to provide a method that doesnt require any special ordering of materials or supplies.. everything should be able to be purchased locally...for cheap!

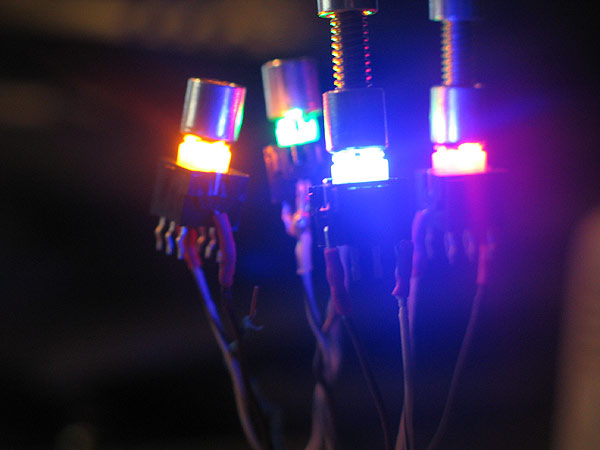

Illuminated Switches: (tiny)

OK.. I talked to the vendor off & on a few times.. and basically for a higher price (and if they are in stock).. he will mix-n-match some switches (led colors) and caps for me:

to re-cap:

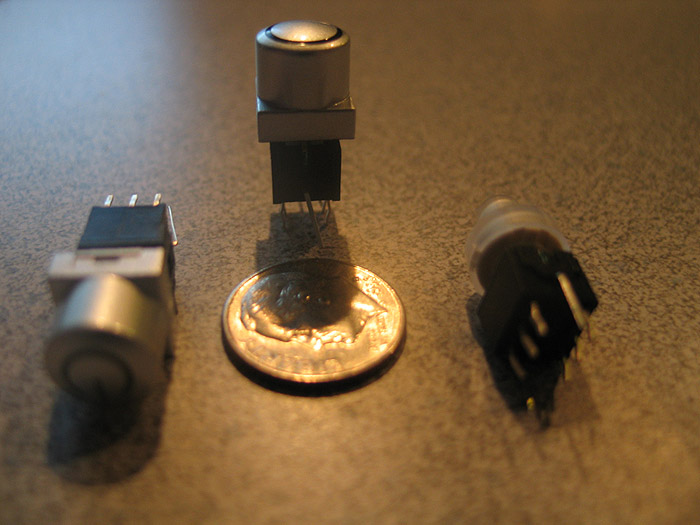

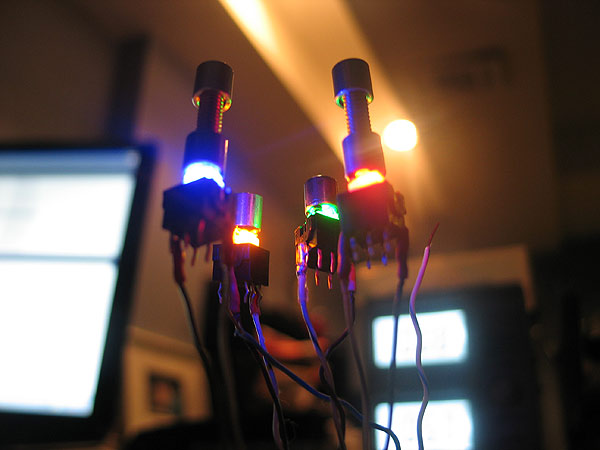

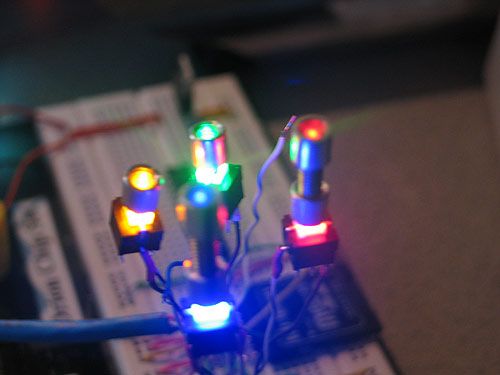

pics of the sample switches they sent me..

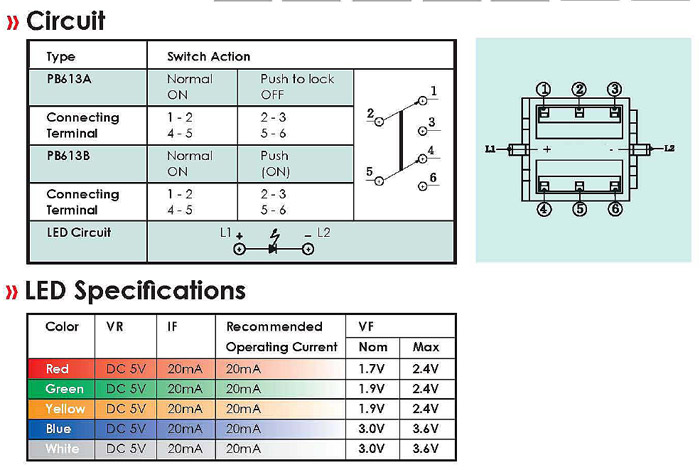

according to the spec sheet:

http://www.rjselectronics.com/PDF/PB613x.pdf

page 2 of 5

it says Switch Action/terminals

Normal ON:

1-2

4-5

Push to Lock/Off

2-3

5-6

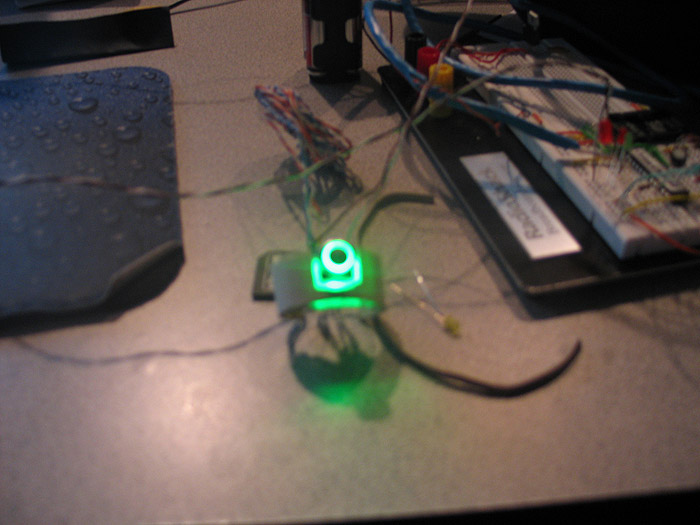

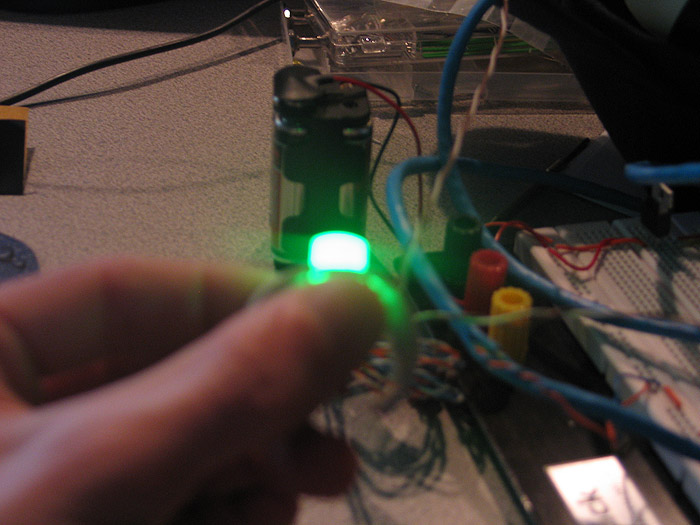

the pics are little 'distorted' because of either my shaky hands.. or taking a pic of the LED lit up..

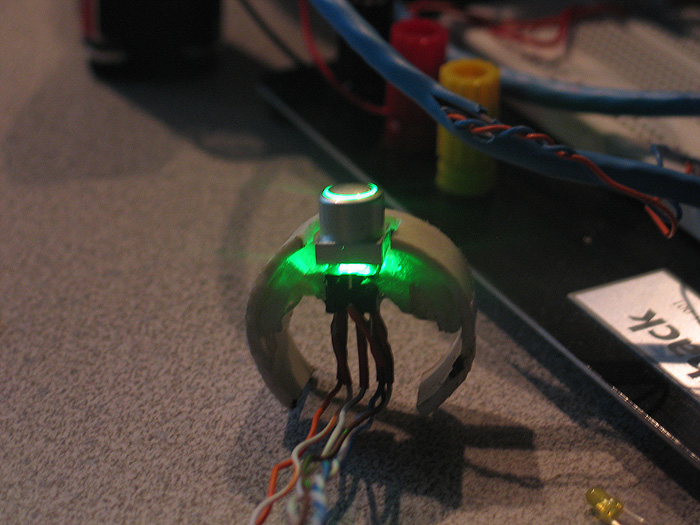

1.) I took all the silver paint off the cap..so the whole thing lights up.. (pretty sick).. tip: to NOT leave the soft plastic/rubber base in while doing it

2.) the second is the default cap with the ring in it.

using the same mounted base.. Im not sure what other colors I got in the 'samples'..

RING:

SOLID:

what we have available to us is:

COLORS:

RED

GREEN

YELLOW

BLUE

CAPS:

BLACK

SILVER

I only asked about getting the RING style (as pictured) but in black and silver (silver is pictured)

If there is enough interest.. I will try to scrounge up the rest of the loot to get an order..

Im thinking they will go for about $5 each shipped..

let me know.

Thanks

------------------------------------ [part II]--------------------------------------------

I had made comment about it previously..and am just now getting around to posting the pics I took of these..

My first attempt at using (mounting) these was much along an early Jay-Gon approach using a PVC 'ring' or semi-ring that could 'flex'.. but that solution left things very close to being a 'one way' switch install without potential damage...

so I began to think about alternate ways to mount these (or other difficult mounting switches)..

when I saw Erv's post about modifying the CAPS.. it reminded me to post what i came up with.

Ervs way of modifying the caps is awesome.. (I'll be doing a few like that for sure).. but not everyone has access to a lathe like we do....

it also leaves you stuck with the having a cap style of choice with the bottom ready to 'snap' to the switches stem..

my approach sorta gives you more room to be able to utilize different (metal, ala Madcow) style switch caps for example.

my first prototype was made from not wanting to waste such a small DPDT latching type switch..(just because I had blown the LEDS in 2-3 of them..)..ssshhhh

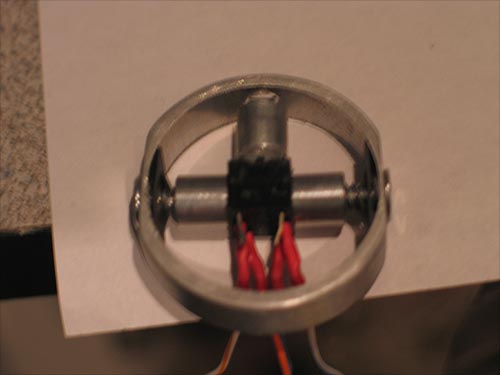

Something that could fit and be easily mounted inside (1.25 ID) a hilt of a normal MHS section..

and also allow for easy cap fitting from the outside.. (like Erv showed on modifying the cap OD)

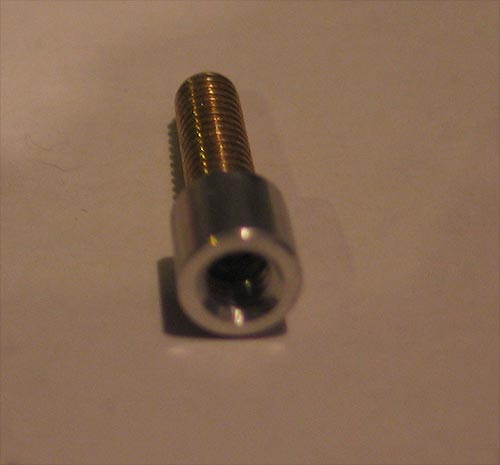

I also took it one step further...and drilled out the stem on one of the thumbscrews so I can mount any type of head I want on it.. (even one with epoxy in it, similar to the screws that let light show through)

its basically a section/ring of 1.25 OD aluminum tubing...with some screws and speed nuts..etc.. with some thread aluminum spaces.. everything can be purchased at Ace Hardware or the like..for a couple bucks..tops.

might throw a dab of hot glue over it just to make sure it doesnt loosen up..but its been very stable so far..thrown all over the place..for weeks now..

I'll get the rest of the pics up, of the threaded stem being illuminated..

(I just need to put he dab of epoxy or something in the tube to diffuse the light more..)

the last pic is where the dab of epoxy will go..

Im hoping it will look like an illuminated, metal 'Madcom' style switch.

the cool thing is..with this 'ring' type set-up.... (much like my approach to chassis' and crystal chambers...etc) it utilizes the pre-built MHS 'feature' of the space in the threads... and to lock down the ring..

this one in the picture fits (tightly) in a 2" section.. in the space left over by the HEATSINK drop down...and having one of my chassis 'disks' locked in by male threads on the other end..

so whats that? a little over 1/4 inch or so?

not 'precision' made, (Im sure others could made a better looking one)...but its not too bad..and you dont need anything fancy... drill/drill press and maybe a sander to grind the sides flat.

feedback? thoughts? improvements?

I'll get some of the illuminated ones posted...

anyone have a suggestion on what to fill the top with first? (epoxy/hot glue)?

---------------------------------------------------------------------------------------------------------

Yeah..looks a little more 'technical'.. and isnt an eye sore in a build..

I have even integrated this 'ring' section into one of my chassis disks (so its all one piece of aluminum)..

so the chassis disk 'portion' gets sandwiched between the male threads and the internal threading 'lip'..and this switch mounting 'section' is after that (still all one piece of aluminum..just turned down a bit for the OD to fit the ID.). ![]()

this diagram might help..

Heavy dueling? I guess I couldnt say.. "I"personally dont duel..

but they are fairly sturdy.. I mean Ive thrown what you seen in the picks around..at walls.. dropped it.. nothing ever moved or popped out of place..

but as I said.. I'll probably just throw a dab of hot glue in the corners to secure it more so nothing gets un-threaded or anything..

but how much 'pressure' you think it'll have on it? and from where? (what point?)

depending on how you implement this type of approach in your project..

(unless the rest of your 'guts' are free floating and sliding all around).. Id say this 'option' whether it be part of another 'disk/section' locked down, or its own ring not secured by anything expect the 'threaded post' of the switch will function & hold up well.

thanks for the looks and comments.. hope someone finds it useful..

---------------------------------------------------------------------------------------------------------

I dont think I ever really posted these images (in public at least) haha..

these are sorta old.. (about the time when I first found these switches and got some samples..and was left with mounting quandaries) ..at the time I was altering a JGJ approach I had seen in some build thread or something..

BEFORE I started working on the 'modular chassis disk' business.....(which is a much nicer looking and more versatile system) haha ![]()

I used what I had available and much of it was hardware stuff..pvc/plastic.

I still find these regular golf club protectors/tubes to be GREAT for chassis building.... and I have used them a few times in the past for stuff..

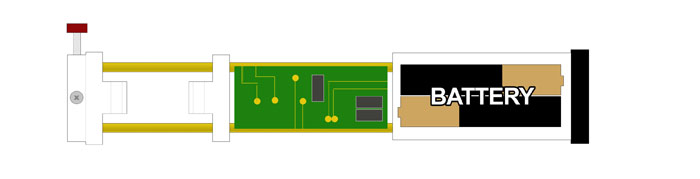

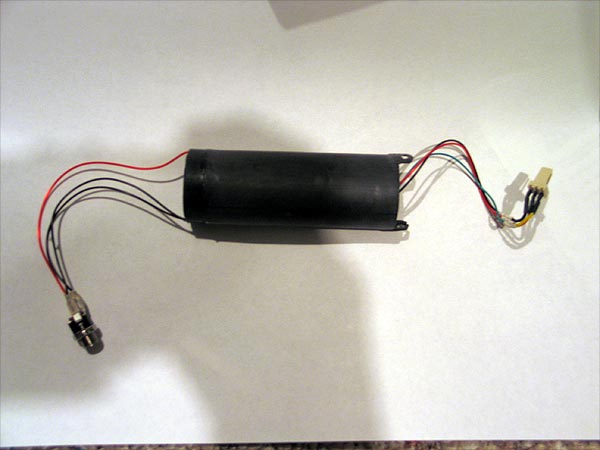

I have my 4.8v Nihm battery pack (the one that TCSS used to sell a while back).. and a speaker mount..

the project this was for has a pommel mount recharge port:

filed 'channels' into the speaker mount so I could run wires past it to the pommel for the RCP..

other end had a 3 wire connector (GND, V++ and speaker) to connect to other sections..

(these innards are very modular themselves)..

battery/speaker section

switch section

sound/driver board section

**legs/ladders on the ends with holes in them..as that is where the switch ring mounts/connects to that piece (very rigid)

soundboard/driver board:

using part of PCV and old 616 mount..

I have, the 616, Plecter dimmer, 2 clash sensors.. (before we did bulk order..thanks AK)..

I think I studied with Eastern to get some cram-fu lessons in this thing (**bonus pic at end)

use the top/lid of film canister to make a 'cap' so to speak so nothiner metal would short out on the switch mount ring/chassis

all 3 section together get me this:

all of it fit inside MHS ID.. the the speaker sanded to press fit and it 'tight' and secure..

its nice little core... nothing fancy since its plastic and a little hot glue in places..

here is a pic of the ring mounted in the battery/speaker section..

wires are tight & clean... (I could have probably shortend some of these in hind site to make fit easier).. every is of course heatshrinked and everything is in male/female connectors..

switch has connector (so it can be serviced)

speaker/battery section has connector

led is of course quick connect as well...

for bonus points..

I solders a clash sensor to plecter dimmer for the flicker effect on clash (needs fairly fresh batteries to see it well)

I also soldered a momentary switch to the plecter dimmer board so you can access the menu and change the flicker effect, ramp up/down times..etc..

and mounted it in the 616 board.. looks nice..

no wires seen on top.. so if you want to switch the sound font to be jedi or sith..you can also use the momentary button to access/set the dimmer options as well

these switches.. are 'very cool' IMHO.. and being illuminated shows even more possibles.. (watch for 'custom' illuminated switch heads post soon)

I think these way of mounting is VERY practical..

why?

it can be done by any/everyone with or without a lathe.. 1.25 OD tube.. a tube cutter.. a drill/drill press.. and a sander

it can be incorporated into other 'sections' of a chassis fairly easy..

when you see the version that is incorporated into the modular chassis disk it makes it 'all' look so nice and professional.. instead of a nice chassis.. (made out of whatever).. and then some button/switch hot glued or wires running long was down the chassis..

anyways..hope you all like..and it helps others mount these switches (or anything for that matter.. tiny recharge port of Easterns for example..) (hint hint)

--------------------------------------------------------------------------------------------------------------------

wrap this thread up..

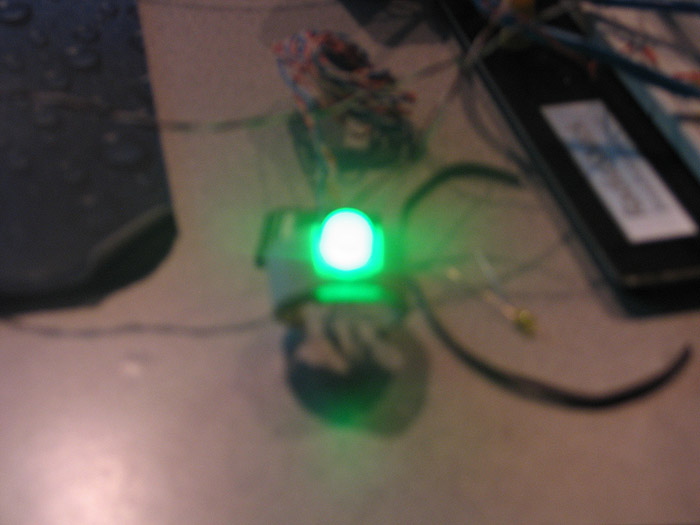

here are some of the pics of the switches and the colors of the LEDs (while on)..

you can see the style of caps Ive been using/making to:

1.) deal with easier mounting

2.) still utilize the illuminated/led option of the switches.

these have hot glue in the caps to diffuse the light.. (its too 'clear', something more 'foggy' is needed to diffuse better)

(I also think the small 'hole' in the threaded stem limits maximum illumination as well..)

I have another pic (cant find where I saved it!?) haha.. showing how 'low profile' you can get with alternate cap/heads (like a metal thumb screw)

I think either turn down the stock caps OD/base on a lathe..or making a custom stem/cap combo is he best way to go for these...

with the aluminum 'heads/caps' picture above.. you can actually almost 'flush mount' them depending on the 'ring width' on where internally it is mounted in your part.

later...

------------------------------------------------------------------------------------

update: thanks to tip provided by 'erv', these switches can be both (default) latching.. and after a mod can also be a momentary switch! great tip! and makes these even MORE useful.

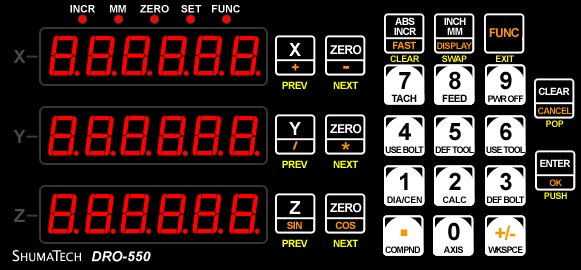

Shumatech DRO-550 Build-Log

Shumatech DRO 500 DIY:

Link: http://www.shumatech.com/web/products/dro-550/power-buy

http://shumatech.com

SHUMATECH DRO-550 PROJECT: [PARTS LIST]

$75.00 (may go down... this is w/o taxes & paypal)

Shumatec DRO-550

http://www.shumatech.com/web/products/dro-550/power-buy

DRO-550 Board (itself)

*all surface mount components pre-soldered

* extra's (below) are what needs to be soldered, (through hole/easy components)

$16.19 (extras)

http://www.shumatech.com/web/products/dro-550/power-buy

9 RED 7-segment LEDs $7.47

5 RED 3mm indicator LEDs $0.77

23 Keypad tact switches $4.14

23 Black tact switch caps $1.84

1 Program tact switch $0.17

2 2-pin MTA headers $0.13

5 3-pin MTA headers $0.44

5 4-pin MTA headers $0.58

5 2x2 Header $0.35

5 Shunt jumper $0.30

Parts needed to complete DRO-550 kit/build: (outside from above parts)

DRO-550 Specific:

$11.25

Hammond 1599HBK Unmachined Case:

http://www.wildhorse-innovations.com/in ... oductId=90

$17.99

DRO-550 Internal Cable Kit:

http://www.wildhorse-innovations.com/in ... oductId=89

$19.99 x 1

DRO-550 (speciic) Case - Machined:

http://www.wildhorse-innovations.com/in ... oductId=88

$14.99 x 1

DRO-350 Faceplate

http://www.wildhorse-innovations.com/in ... roductId=6

$1.75 x ??

Mini-Din Plug

http://www.wildhorse-innovations.com/in ... oductId=24

$12.99 x 1

AC Adapter - 9vdc @ 1.2a

http://www.wildhorse-innovations.com/in ... roductId=7

If you want to be 'ahead' of the game.. maybe contact

www.wildhorse-innovations.com

(I did) and they told me they were going to stock DRO-550 specific stuff this week..

just checked for ya..

cases, internal cables..DRO-550 specific..

for you.. you may want the un-machined cases..and do them yourself to fit whatever specs you want/like?

unmachined:

http://www.wildhorse-innovations.com/in ... oductId=90

DRO-550 internal cables:

http://www.wildhorse-innovations.com/in ... oductId=89

DRO-550 specific machined case:

http://www.wildhorse-innovations.com/in ... oductId=88

update on FINAL costs:

Fixed Costs

Item Estimated Cost

NRE (Stencils, SMT programming, PCB tooling) $1,785.00

Setup (Manufacturing setup) $342.00

Prototypes (2 development prototypes) $525.96

Subtotal

$2,652.96

Recurring Costs

Item Estimated Cost

Material (Raw parts costs) $47.42

Labor (Human labor costs) $30.08

Subtotal

$77.50

Extra Component Costs

Quantity Component

Estimated Cost

9 RED 7-segment LEDs $7.56

5 RED 3mm indicator LEDs $0.25

1 Piezo Buzzer $1.28

23 Black tact switch caps $1.61

1 Program tact switch $0.33

2 2-pin MTA headers $0.08

5 3-pin MTA headers $0.30

5 4-pin MTA headers $0.40

5 2x2 Header $0.85

5 Shunt jumper $0.25

Distributor Shipping + Kitting Supplies (TBD) $2.00

Total

$14.91

Per-Board Costs (With Extra Components)

Item Estimated Cost

Fixed $4.82

Recurring $77.50

Extra Components $14.91

PayPal (3.9% + 2 x $0.30) $4.58

Total

$101.82

Per-Board Costs (Without Extra Components)

Item Estimated Cost

Fixed $4.82

Recurring $77.50

PayPal (3.9% + 2 x $0.30) $3.97

Total

$86.29

----------------------------------------------------------------

Adding some links and what not that we can use to refer back on when we get these things..

I want to be able to use this to its FULL potential..

I think once I get my mill..the bolt hole pattern feature will be a featured used quite often by me.

some of links will be to DRO-350 stuff.. user guides..etc.. because I feel useful info will still be there..

also some of these are un-official guides NOT form the developer (but were highly recommended)

I think the Users Guide of the DPU-550 will be the closest for what is in the DRO-550...Users Guide (which is coming any day now)

Rick Sparber: (unofficial docs)

http://rick.sparber.org/sh.htm

Shumatec: DRO-550 Hardware Manual

http://groups.yahoo.com/group/ShumaTech ... Manual.pdf

DRO-350 Users Guide: The official DRO-350 User's Guide for software release 4

http://www.shumatech.com/products/dro-3 ... /guide.pdf

DPU-550 User's Guide: Daughter board to DRO-350

http://www.shumatech.com/products/dpu-5 ... RO-550.pdf

Chinese Scales:

A technical descrition of the Chinese scale protocol and their operation.

http://www.shumatech.com/support/chinese_scales.htm

The Chinese Scale Experience

Bill Havins, a user of the ShumaTech DRO-350, wrote a great article on his experiences using Chinese scales. The artice covers where to purchase Chinese scales, their installation on equipment, and general troubleshooting.

http://www.shumatech.com/support/Chines ... rience.pdf

OPEN DRO Project:

http://opendro.sourceforge.net/

a nice feature/add-on was posted about using the two extra axis for a min LCD screen..

looks trick..

http://www.shumatech.com/web/products/lcd-200

----------------------------------------------

ok boys...

I know Alan, Erv & Goodman all got these DRO's (or are coming soon)..

they overlays on the shumatech sites are available now..as wella sthe LCD add-on kit (and overlay for that as well)

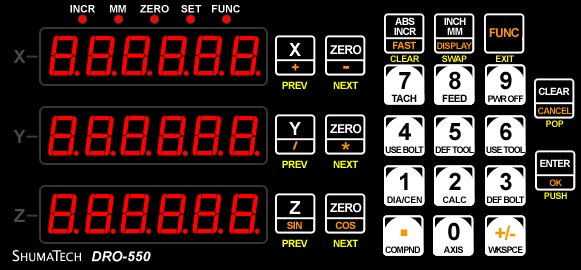

that being said.. I gave it a shot at making my own overlay..

and Im releasing it here for anyone lse that may want to use it.. or in fact edit it..as I am including the source .psd file as well.

Also included in the .psd is the BASE TEMPLATE for the enclosure milling specs (where the cut outs are)

alternately.. if anyone wants something custom done.. just let me know.. (ie: diamond plate background...... or you companies name in the corner.. different color scheme.......whatever)

this first version was me trying to be minimal and clean..

it is based off of my first 'mock-idea' (and is almost identical)

hope you guys like it.. (working a backlit idea/version currently)

http://dmstudios.net/misc/DRO-550/DRO-5 ... inimal.zip

-------------------------------------------------------------------------------------------------

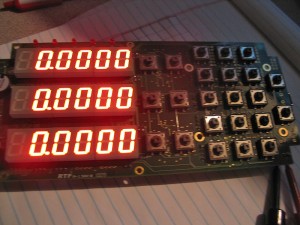

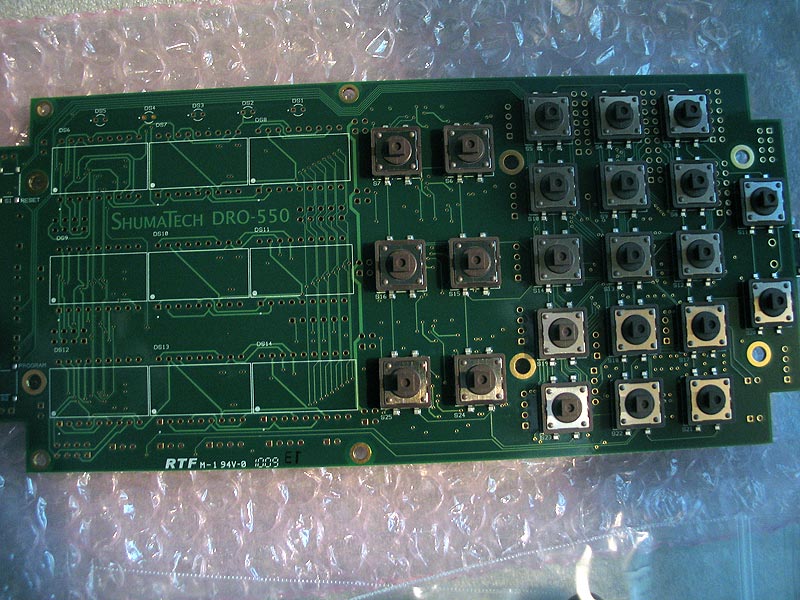

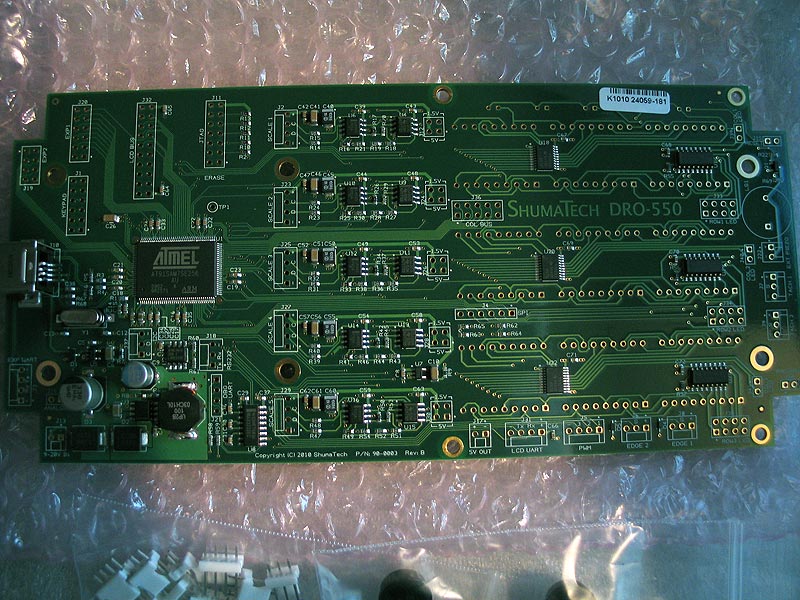

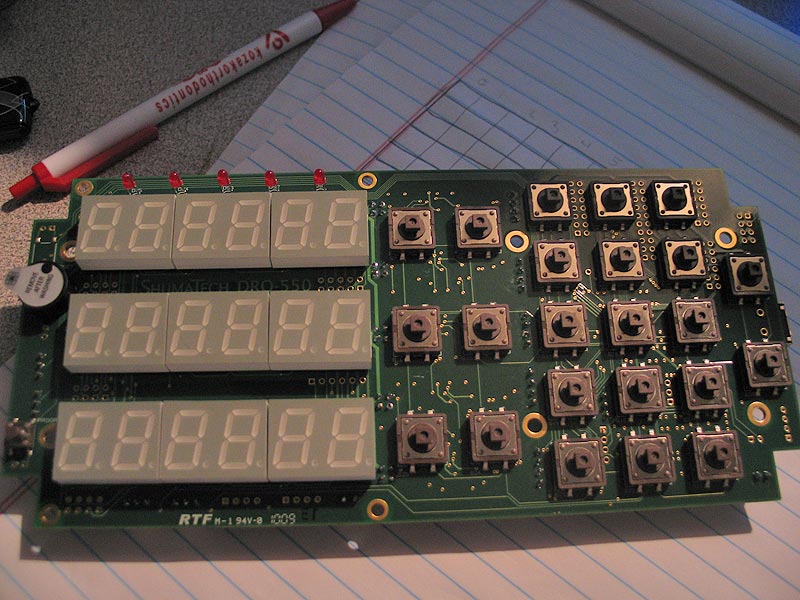

my DRO-550 arrived..packed nice..and no problems so far..

still need to order my case/enclosure..internal cables..etc..

but the MAIN portion is here (I got two of them)

the 'kit' pic: (sorry its blurry)

top:

bottom:

man..getting those SMD components installed for us..and the buttons too for an extra $4 was WELL worth it..LOL

there are some polls up for some of the overlays..and some other questions (if you guys are interested)

I think by default..they come with RED numeric displays... anyone changing to green? (they look sharp).. or another color? I have been able to find a BLUE in the same package/footprint as the one for the DRO-550 uses.

figured Id post with the first update..Im curious to watch and discuss others builds too..

-------------------------------------------------------------------------------------------------------------------------

took some time last night.. to finally look into things more..

Im excited..and this 'project' looks very fun.

I have gathered the files needed for everyone else..

here are the links as well (which I recommend..they step by step walk you trough set-up)..

Construction:

http://www.shumatech.com/web/products/d ... nstruction

PDF:

http://groups.yahoo.com/group/ShumaTech ... 0Guide.pdf

Software:

http://www.shumatech.com/web/products/dro-550/software

PDF:

http://groups.yahoo.com/group/ShumaTech ... 0Guide.pdf

Hardware:

http://www.shumatech.com/web/products/dro-550/hardware

PDF:

http://groups.yahoo.com/group/ShumaTech ... Manual.pdf

OpenDRO Software:

http://sourceforge.net/projects/opendro/files/

SAM-BA:

http://www.atmel.com/dyn/resources/prod ... 0v1.13.exe

(Im also really diggin' this LCD add on for the other extra functions/axis..etc)

http://www.shumatech.com/web/products/lcd-200

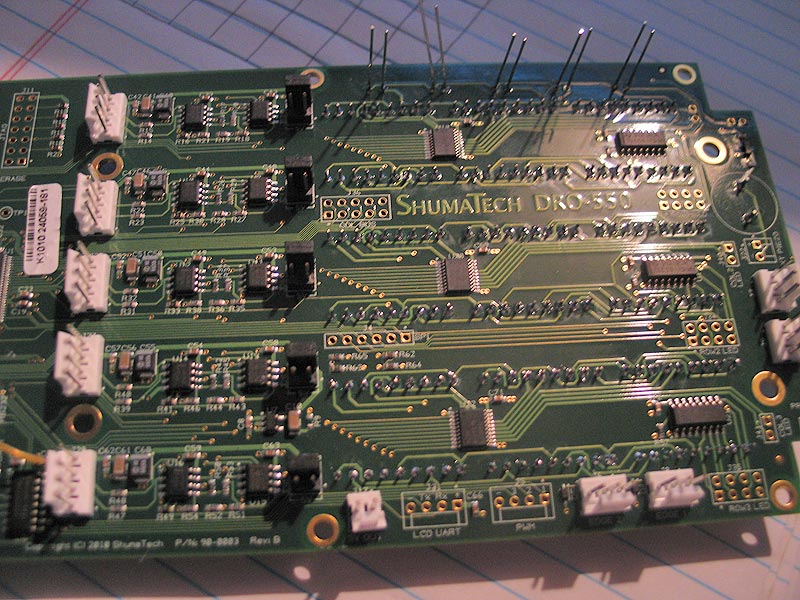

I took out 1 of my boards last night.. grabbed the "Construction Manual" (linked to above)

had done all prelim tests

(measured resistance at certain spots)

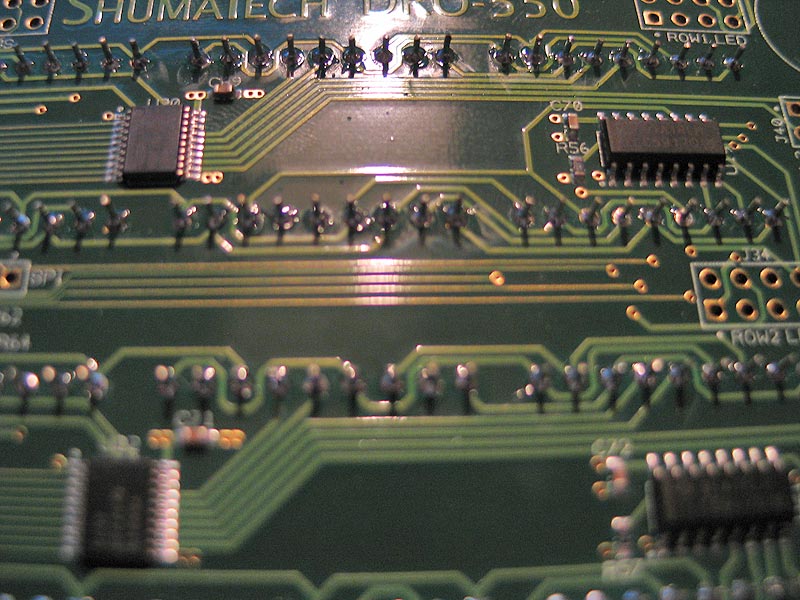

soldered in ALL headers & tact switch

hooked it up to my PSU using 9V @ 1.5A

metered certain points to check 5v, 3.3v, 1.5v, 1.8v, etc (all was perfect)

hooked up to USB port.. installed drivers to recognize chip/board

installed SAM-BA (linked to above)

flash Atmel chip

verified write

(everything was perfect)

I did all of this in about 30 minutes or.. I glanced over the documentation while cleaning up after dinner. knew what I needed.. (already had files downloaded & documentation printed out in binder as well)..

and that was that.

Im 'very' happy with not only the quality, but documentation as well.

This is EASY!!!!

I have NOT installed my display LED's for two reasons:

1.) I do not have an enclosure yet.. and I want to make sure I mount them to be flush and display/light well behind the overlay.

2.) Im not 100% sure I sticking with the ALL RED display LEDS..

(I have been looking for some BLUE one....anybody?)

but may get all green.. or even multi-color.

(ie: 1 color for each axis, X-red, Y-green, Z-amber)

also we can make our own custom overlays as well..the group has been having polls on tons of different versions..

I'll try and post some more pics..

-----------------------------------------------------------------------------------------------------------

I still have NOT ordered my case and internal cable kits..etc (nor scale plugs or power adapter)

anyways here are some pics.. the basic construction will take less than 1 hour.. (less on second units) people who posted it 'only' taking them 3 hours... I was thinking thats not too bad... but now Im like..what the fuck were they doing?

nothing but a ton of headers with through holes to solder to.

check out my soldering.. (not too bad) ![]()

all the headers (overview)

there she is:

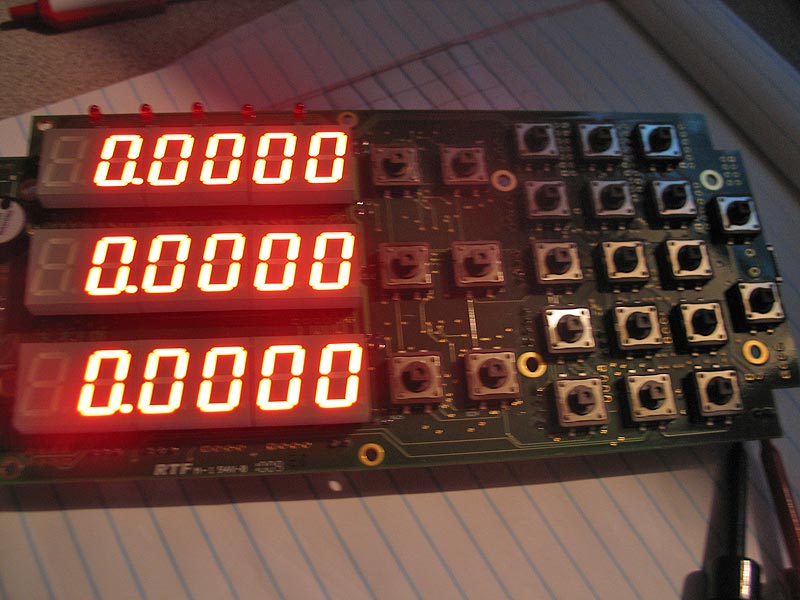

and lit-up:

man there is 162 solder 'joints' to do on the 9 x 7-segment led displays!! plus all the headers! hahaha

here was my submission to the overlay poll/post

can buy order one of the new ones... or make your own at a kinkos or whatever if you want custom color scheme or whatever.. there was some nice ones posted too

-----------------------------------------------------

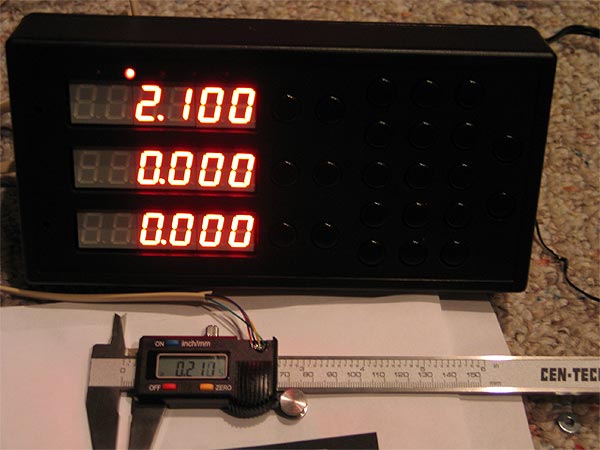

All completed.. (the first one at least)..

the second is all soldered up..just need to assemble case and attach internal cables!

Im digging it so far!

Im making my own overlays..so if anyone wants to file(s)..let me know.

test scale I made..using $9.99 HF caliper...

the first overlay Im finishing up.. (all 300 DPI .jpg's..with included source .psd file)