Another SMT stencil cutting post….

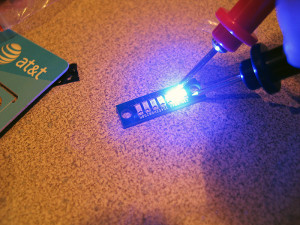

Finally some results! ![]()

I recently purchased a Silhouette Cameo (http://www.silhouetteamerica.com/?page=shop&cat=1)

Aside from all the things that can be done with this machine (cut fabric, vinyl, paper/card stock, etching plastic, cut cake fondant, stickers, signs, wedding cards/invitation, and the list goes on and on...) one of the things I wanted most was to be able to cut SMD/SMT stencils for making pcb's at home.

It has been a 'trend' lately, seeing the idea pop-up on HackADay , IdleLoop, DangerousPrototypes, and other blogs/forums.. so I decided to get to work on what it woudl take for me to produce the same results.

First I want to give a shout out and credit to several people/places as nothign I have done here is 'new' or innovative, its just the results from the hard work and sotware of other people, who decided to share with us, for this purpose. ![]()

HackAday, Idle Loop, DangerousPrototypes, Pmonta, teletypeguy, jessuscf...and everyone else I forgot.. ![]()

http://hackaday.com/2012/12/27/diy-smd-stencils-made-with-a-craft-cutter/

http://www.idleloop.com/robotics/cutter/

http://pmonta.com/blog/2012/12/25/smt-stencil-cutting/

http://dangerousprototypes.com/2013/05/17/cutting-stencil-using-a-silhouette-cameo/

(Im sure there are others.. but these were mains one..and they all link to each other or have a list of links in the articles themselves to oter relevant info)

With that out of the way..

the general overview of everything I have tested and read basically boils down to, there are only to 'viable' approaches that are worth the 'effort'.

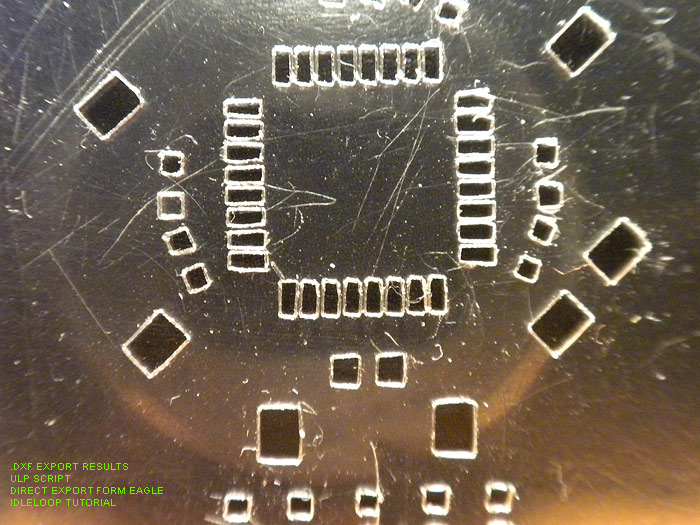

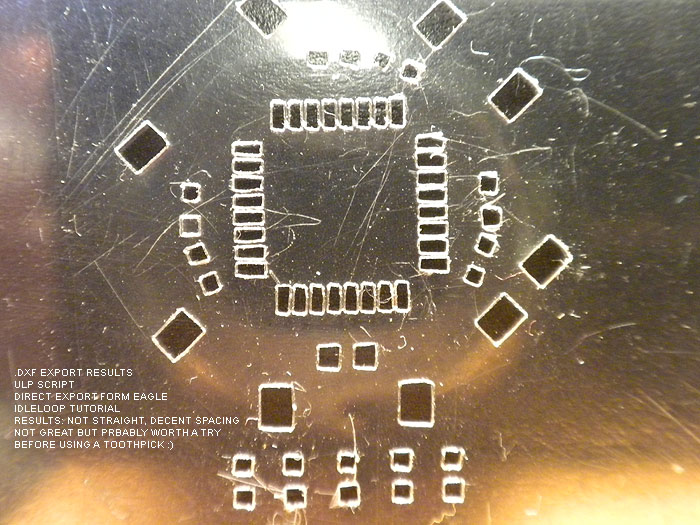

Approach 1: Involves exporting a .dxf file directly from SoftCAD Eagle pcb design software, and you inturn import that .dxf file into the default Silhouette Studio software that comes with you Silhouette Cameo.

This is the approach outlined here at:

IDLE LOOP - http://www.idleloop.com/robotics/cutter/

by Cathy Saxton

The ULP script is located here on github: https://github.com/SWITCHSCIENCE/ssci-eagle-public/blob/master/cream-dxf.ulp

(not sure of the author..sorry)

* Dont forget to turn off "scale to fit" for DXF import in your Silhouette Studio preferences.

This is by far the EASIEST approach one can do/try... (its not much different than using your Cameo to open/cut any other .dxf file at this point.

However.. the results were 'ok' (at best!).. and with soem tweaks 'usable' probably with some 'fixing' afterwards..

I experienced the same results as many others on the net have experienced..

not 'straight' cuts.. bowed out box lines, alignment problems..etc

Results: 'ok'.. probably 'usable', maybe with some fixin'/clean-up..

better than a toothpick and doing it by by hand I would imagine. ![]()

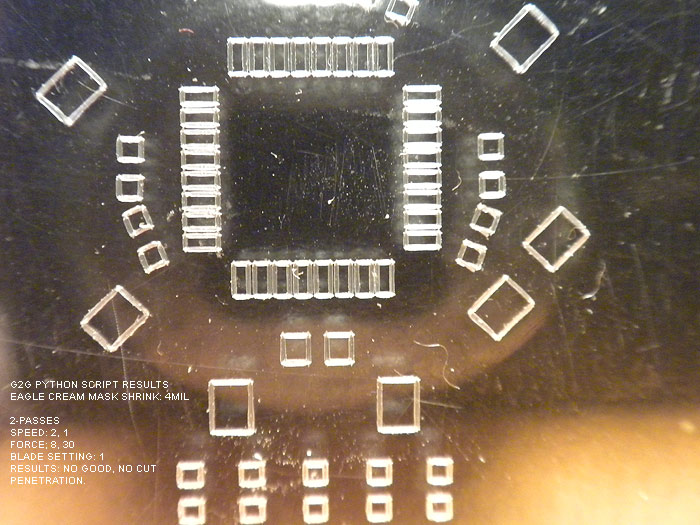

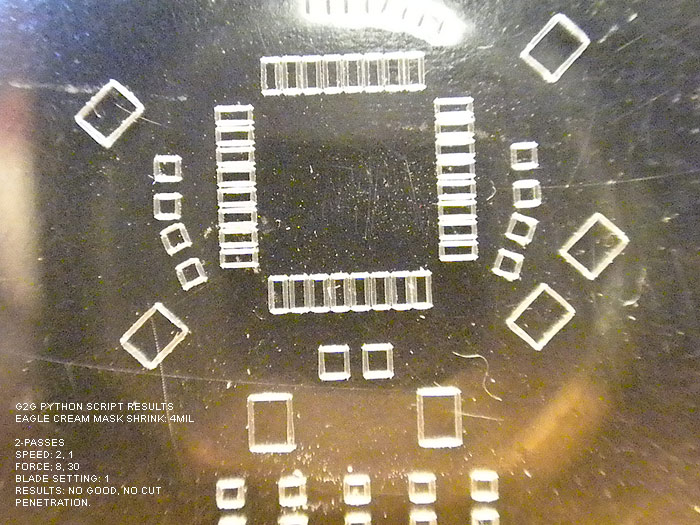

Next up is the GerberToGraphtec approach. This works DIRECTLY with the gerber file exported from your design software..

and is Python based...

This script/project is by: Peter Monta

http://pmonta.com/blog/2012/12/25/smt-stencil-cutting/

Github files: http://github.com/pmonta/gerber2graphtec

Being on Windows. this was a bit of a learning curve, and require the installation of several supporting apps.

(and not to mention I'm pretty much command line retarded)

Anyways.. download and install these app sin their default locations:

Python 2.7.5: http://www.python.org/

Gerbv 2.6.0: http://sourceforge.net/projects/gerbv/files/gerbv/gerbv-2.6.0/

pstoedit 3.61: http://www.pstoedit.net/

Ghostscript 9.07: http://www.ghostscript.com/download/gsdnld.html

As mentioned here: http://dangerousprototypes.com/forum/viewtopic.php?f=68&t=5341#p51495 in a post by: jesuscf..

he mentioned, for WINDOWS USERS.. we need to edit the gerbertographtec file.. (from what I have read it 'just works' for Linux and Mac.....figured I'd mention it to make you guys happy)

Download the .zip file and extract the folder inside...

Find the gerbertographtec file and edit it as follows:

1.) add the .py extension to the file name (to be able to run the program directly from a command prompt)

2.) Change these two lines:

os.system("gerbv --export=pdf --output=%s --border=0 %s" % (temp_pdf,input_filename))

os.system("pstoedit -f pic %s %s 2>/dev/null" % (temp_pdf,temp_pic))

to:

os.system("\"C:/Program Files (x86)/gerbv-2.6.0/bin/gerbv\" --export=pdf --output=%s --border=0 %s" % (temp_pdf,input_filename))

os.system("\"C:/Program Files/pstoedit/pstoedit\" -q -f pic %s %s" % (temp_pdf,temp_pic))

*He mentions this is because some of the apps above (gerbv & pstoedit) added their executable folders to the path.

One of the final steps is 'sharing' out your Silhouette Cameo printer, in the Printers & Faxes screen in the Control Panel.

(right click >> sharing & security >> share this printer (name it: Cameo)

At this point, I had some problems with the command line stuff he was posting to use to initiate the process and start cutting:

C:\gerber2graphtec-master>gerber2graphtec.py test.gbr > result.txt

C:\gerber2graphtec-master>copy /B result.txt \\[YOUR COMPUTER NAME]\Cameo

alternate line to use: (not tested)

C:\gerber2graphtec-master>gerber2graphtec.py test.gbr > \\[YOUR COMPUTER NAME]\Cameo

I had tested things as described and kept getting error after error.. (not sure if it was a pathing problem, or installation problem on certain supporting apps)

either way.. I ended up just using a .bat file another member (teletypeguy) posted, and uing the same file structure.

that ended up being this:

on _root of C: drive:

Create a folder called: gerber-files-to-cut

ie: C:\gerber-files-to-cut

INSIDE this directory, you put/copy the gerbertographtec folder you downloaded at the github link above (dont forget to edit it as outlined above)

ie: C:\gerber-files-to-cut\gerber2graphtec

and the .bat file I created/used was this: (use your computer name, not [computer_name]

@echo off

rem This is for printer named "Cameo" which must be named and shared in control panel.

rem This is for computer named "hacker"

echo.

echo This script will send gerber file to Cameo for cutting solder stencil.

echo Generates intermediate files .pdf, .pic, and .graphtec.txt

echo.

echo Set your Cameo blade to 1 and turn cutter on.

echo Load mylar sheet (landscape) at upper-left corner of mat.

echo.

set /p filename= Enter filename of gerber (eg: test.spt or board.gbr):

gerber2graphtec\gerber2graphtec.py %filename% > %filename%.graphtec.txt

copy /B %filename%.graphtec.txt \\[computer_name]\Cameo

This .bat file should be INSIDE of the: ie: C:\gerber-files-to-cut directory.

At this point.. you are ready to startm aking test cuts.

Be warned, this a VERY SLOW process, but very accurate and te results are pretty good.

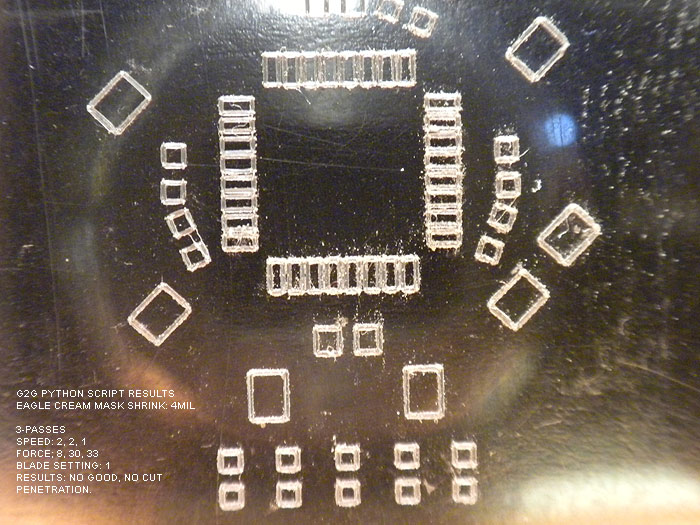

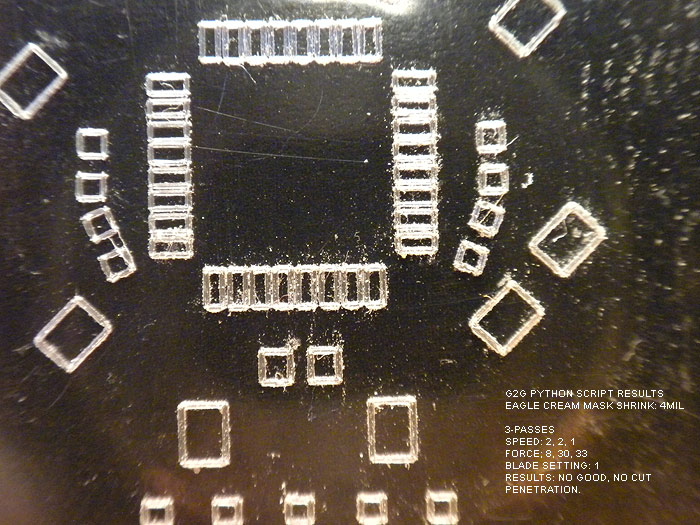

2-passes, pretty much 'stock' configuration

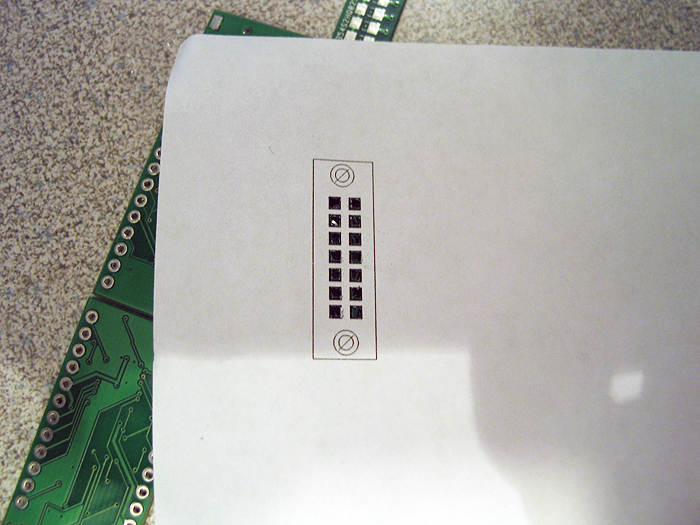

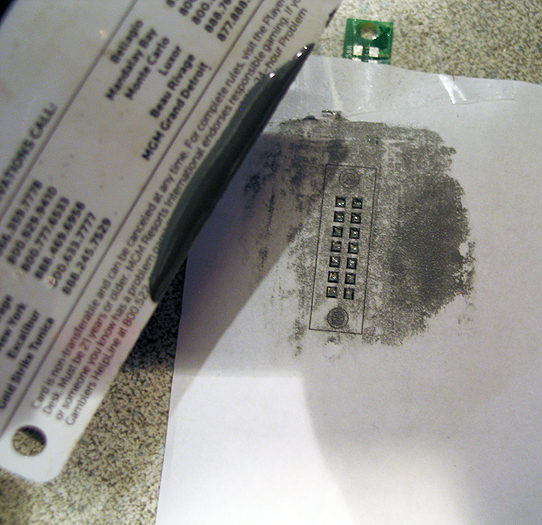

did NOT cut all the way through!!!.. but looked good (pic doesnt really do it justice as the shadow and it didnt cut all the way through making it look 'fuzzy/choppy'.

Edited to 3-passes

result: still couldnt get the cut to penetrate..(backside was still smooth)

ok.. so at this point.. Im thinking: "Geez, the ULP script and .dxf export from IDLE LOOP looks great right about now!" LOL..

no matter what a BLADE SETTING of 1 wont cut it!.. and the holes never were cut out.

blade setting of two was too much and ripped pads!

but I kept reading around and asking questions, and was informed about the defaults in the gerbertographtec.py script..

(about how to add more than 1, 2, 3 cuts, and the force (pressure) parameter as well!)

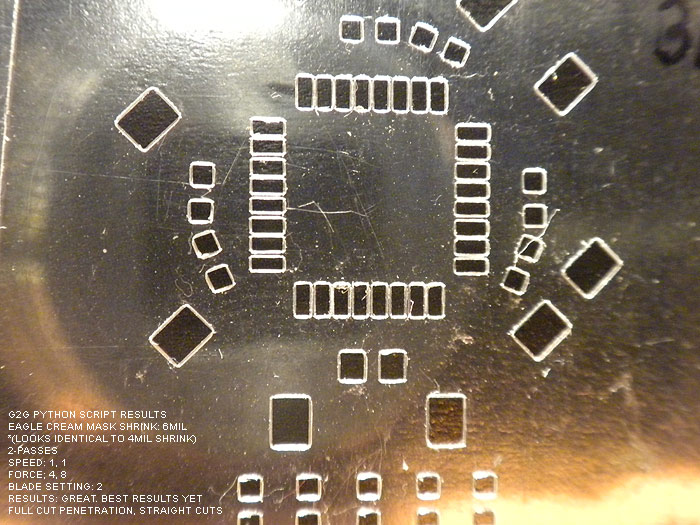

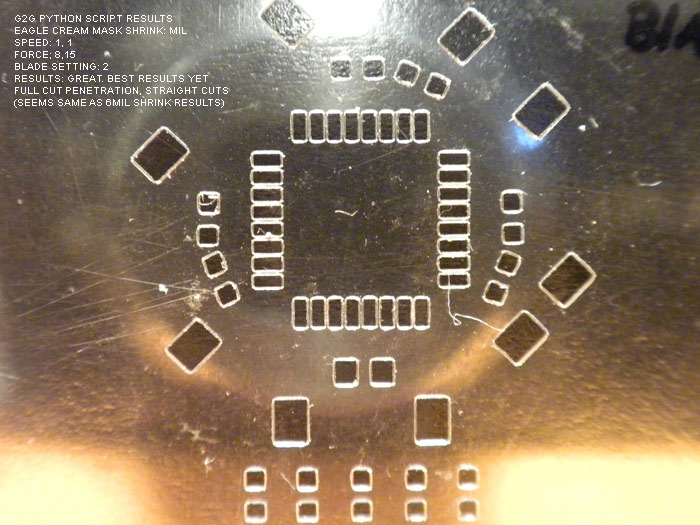

This,.. in addition to the tip on shrinking the CREAM layer in the DRC >> MASKS tab, seemed to charge new life into me!

So I opened the gerbertographtec.py script (I also learned you can add these parameter to the batch script, but I think I was more comfortable editing the .py script itself, and commenting out other 'settings' for later review/use

found these lines/values:

offset = (4,0.5)

border = (1,1)

matrix = (1,0,0,1)

speed = [2,2]

force = [8,30]

cut_mode = 0

and edited them...

the only one I really messed with was speed & force (although by default the script will cut a 1" board around your pcb largest area.. you can change this in the border default)

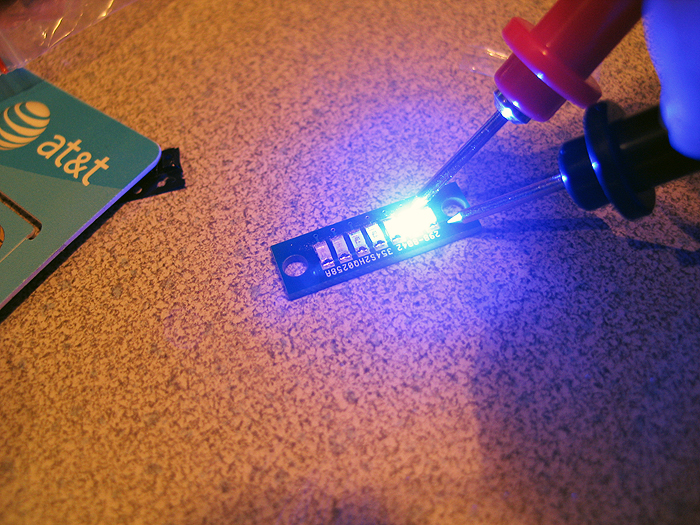

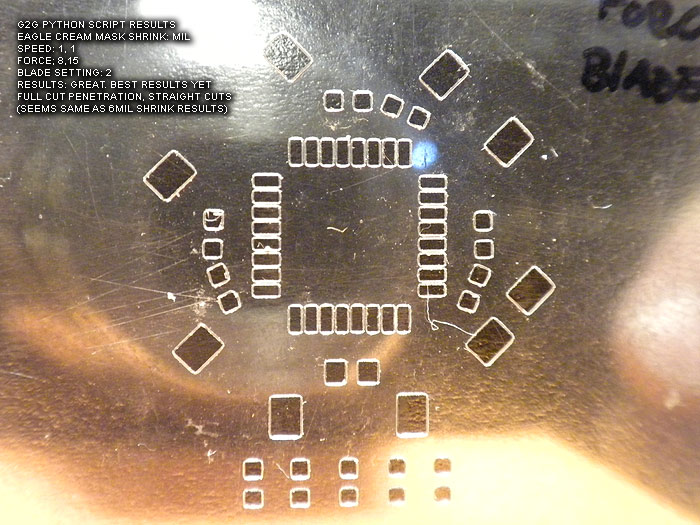

(all images should have the settings used and the results in the image)

Also note that I tried to shrink the CREAM LAYER in Eagle before exporting by 6mil.. and it looked/showed no different than when it was at 4mil.... not sure if it is due to the iTeadStudio CAM file I used to export the gerber files or what?

either way Im happy and impressed with the result so far:

keeping the blade setting at 2..I tried different runs, speeds, and pressure..

here are the results:

At this point. I believe these to not only be usable.. but of 'decent' quality.. (better than the laser ones I have 'paid for perhaps?)...

I am going to be trying the Apollo write-on transparency sheets from the local Home Depot this weekend.

*Project note:

I still get an error/warning every time I run this...

"The procedure entry point ?construct@?$allocator@VVPath@Magik@@@std@@QAEXPAVVPath@Magik@@$$QAV34@@Z could not be located in the dynamic CORE_RL_Magik++.dll"

*****update: by removing the .dll from the directory, this solves the error..

it has to due with either gerbv or pstoedit (I cant re-call off hand).. however I have even tried installing Image_Magik..to get the .dll's and copy/paste them to the directory.. (error persisted)

Love to hear what anyone has on this error and how to fix it!

thanks to all the hardwork and posts of everyone before me and where I source the info/help from!..

its a great 'tool' to have, and a nice ability to not have to source/pay for solder paste stencils any more for hobby/protype work!

update:

at the Dangerous Prototypes forums.. there have been additions done by the members..

* a new .py script hat is optimized for not only faster speed.. but seems to perform better/straighter cuts through the entire stencil/area

* a new GUI for editing the parameters and fine tunign control as been created as well

* Linux and MAC support for the GUI...

IMHO.. this was worth the purchase of my Silhouette Cameo alone.. ![]()

thanks!

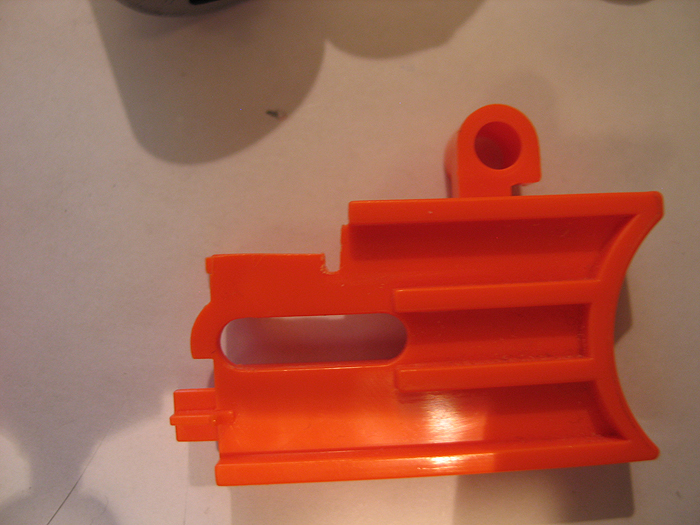

Maverick (Nerf) Mod: custom blaster build log

Looking to do a Nerf gun mod... wanted to get some feedback on how to paint/weather it..

found a few projects on-line that I thought we pretty decent.. trying to decide on my own direction here.

1.) black & silver based (techy) theme

2.) heavy metal/blade runner feel (really digging this one and the wooden/brown handle on it)

3.) Army green & black style:

4.) silver & black (mas effect I think? not a gamer).. really like this style too.. even the logo (of some kind) looks right

5.) mixture, black, silver & brown grip..

Secondly.. a few other questions.. ![]()

1.) how important (cool points?) is that the nerf gun still works as a nerf gun? Ive been thinking of removing the working 'dart' aspect of it.. in favor of some electronics goodness instead?? thoughts?

2.) anyone else have a blaster project in the works??

-----------------------------[update after some work]--------------------------------

update.....

after some work.. I made some progress on this project. ![]()

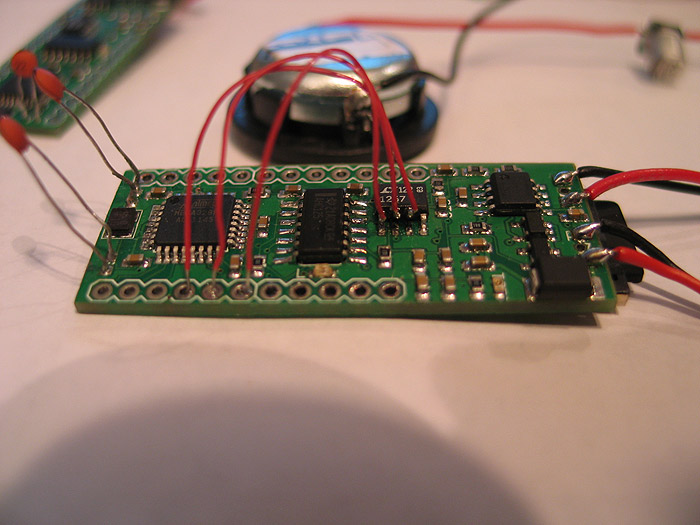

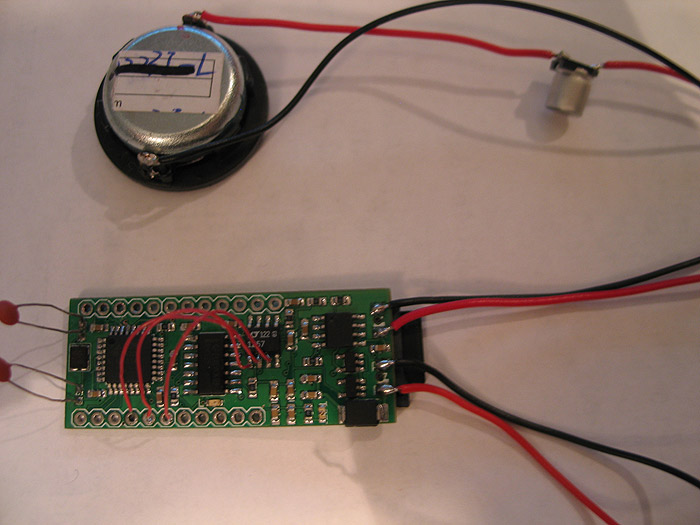

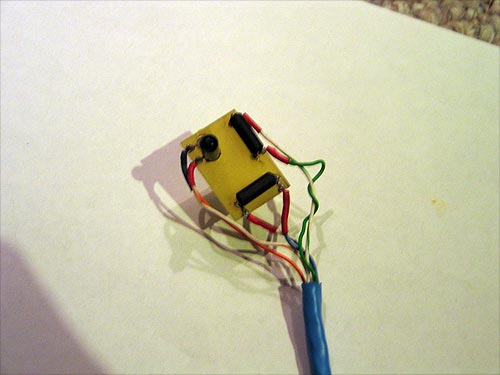

I got the electronics all figured out.. (including making/baking/assembling the board, writing/finalizing the code, home brew/etching two additional custom pcb's...yadda yadda)

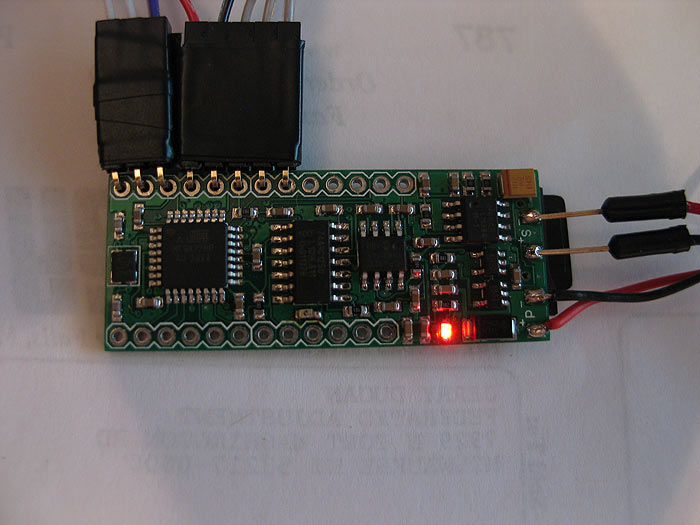

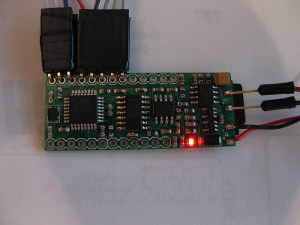

It is powered by S.C.A.B... ![]()

[kinda my generic/general platform for props..so far I love it]

I think I had posted pics of making my board somewhere before.. (in another thread currently running about)..

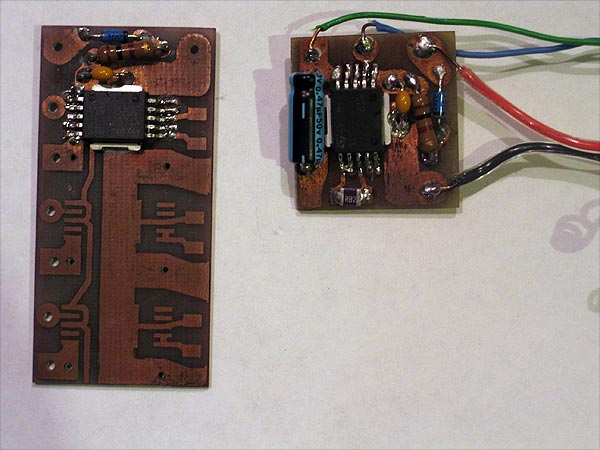

here it was it looks like:

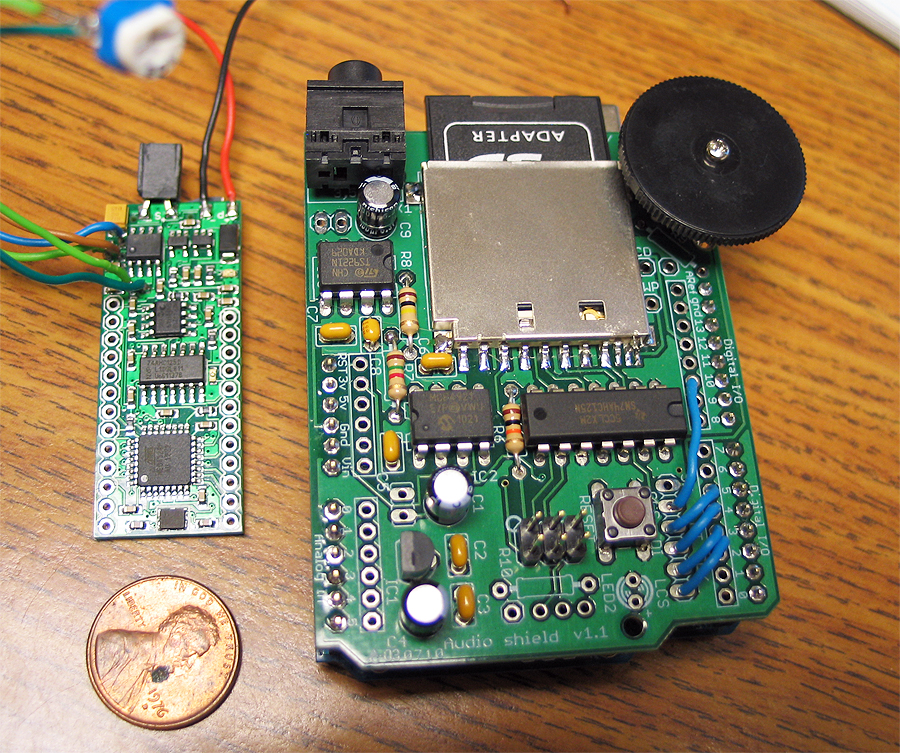

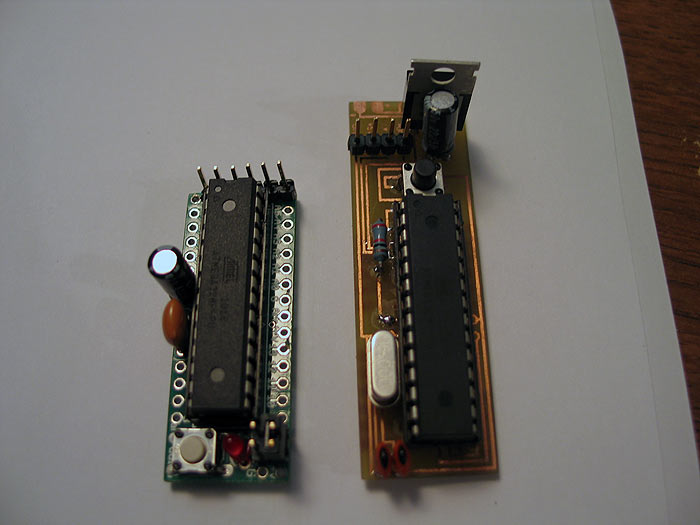

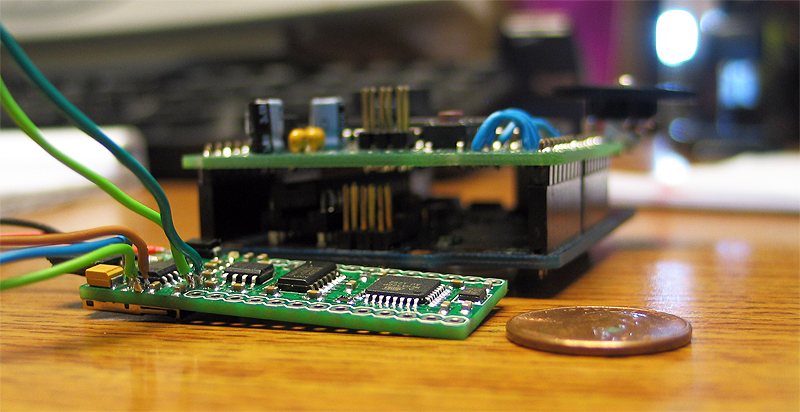

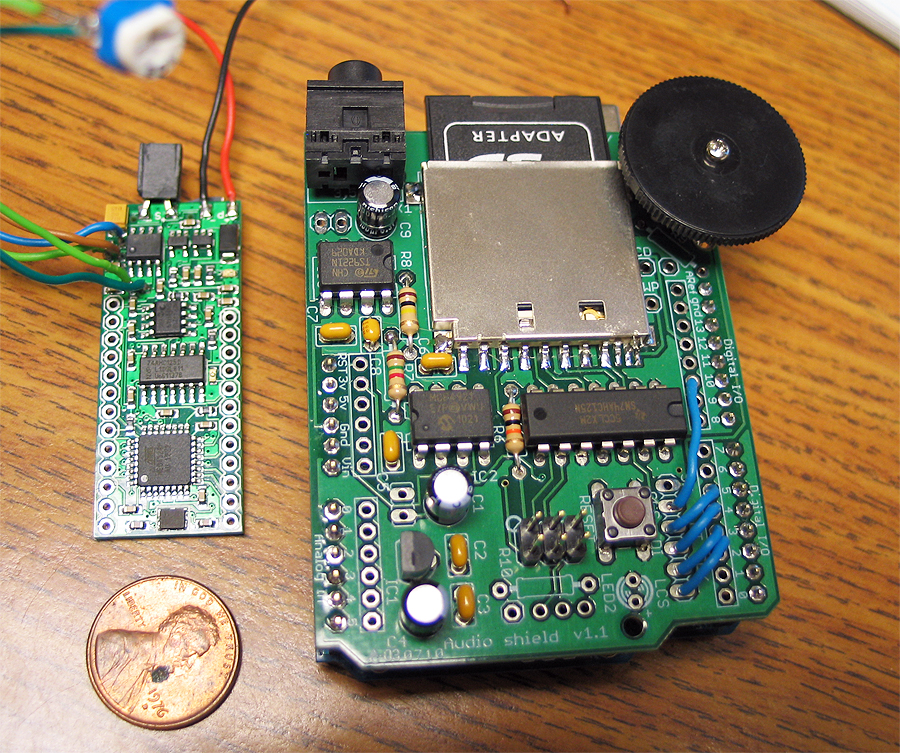

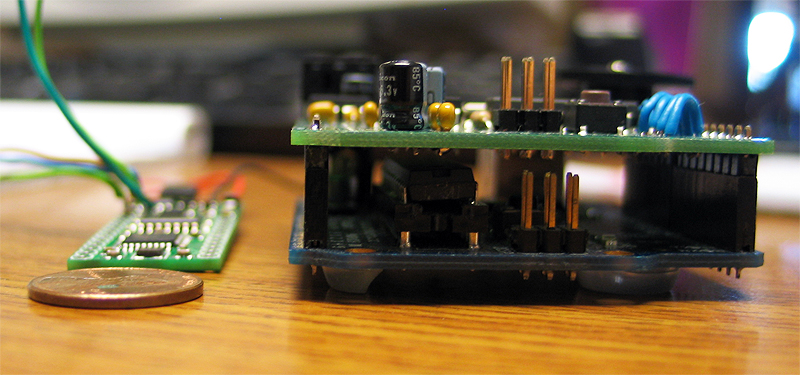

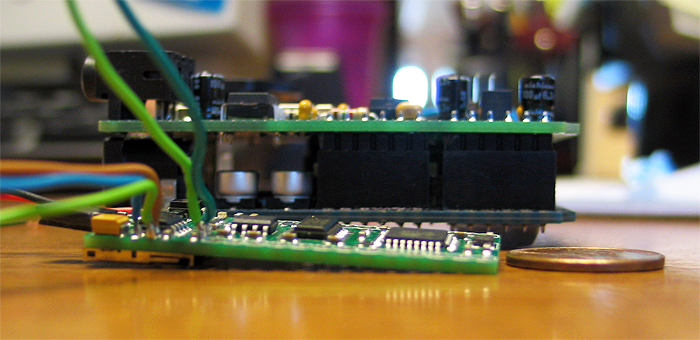

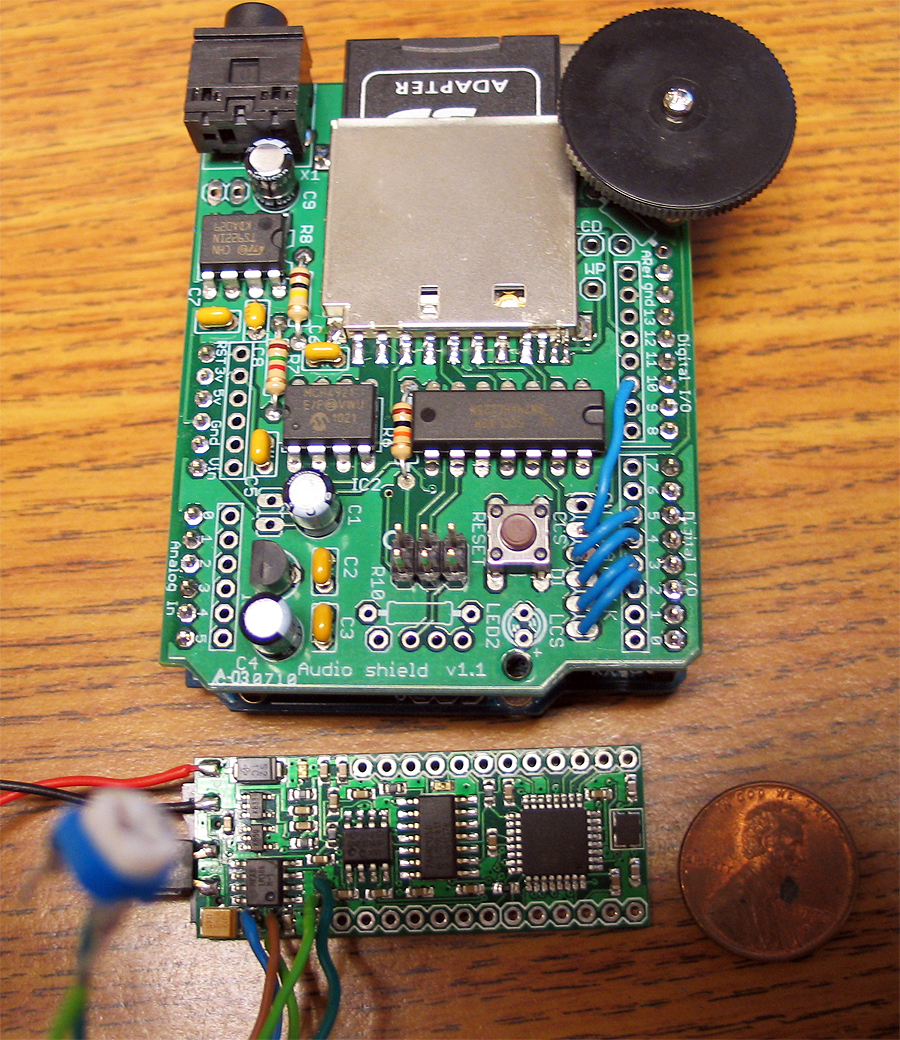

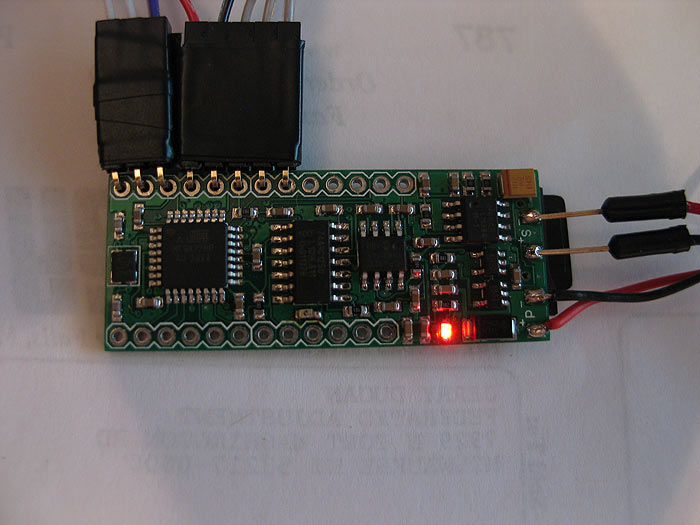

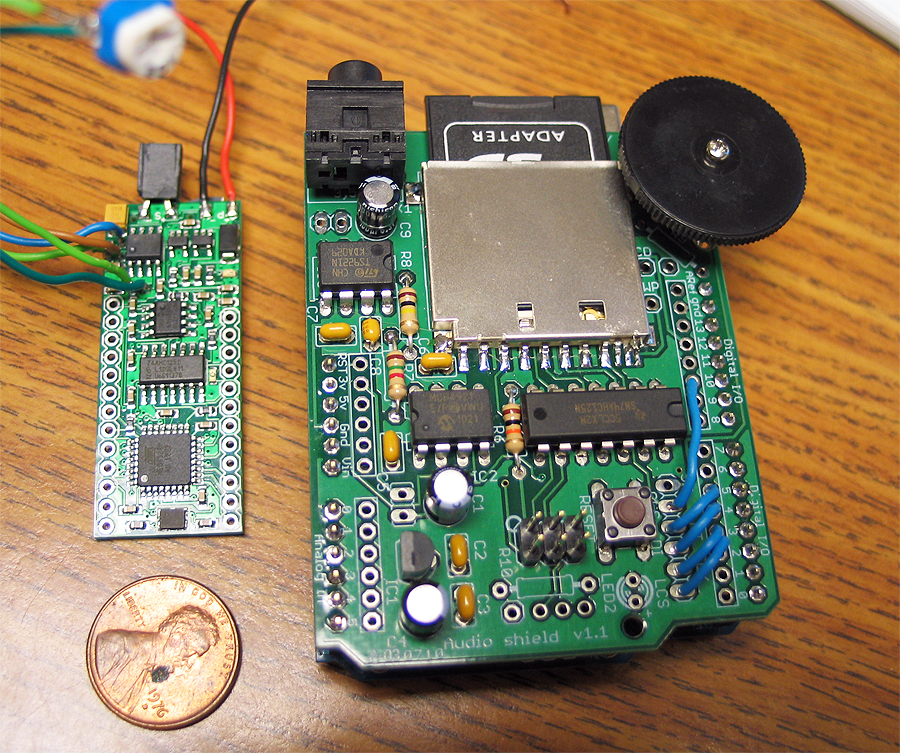

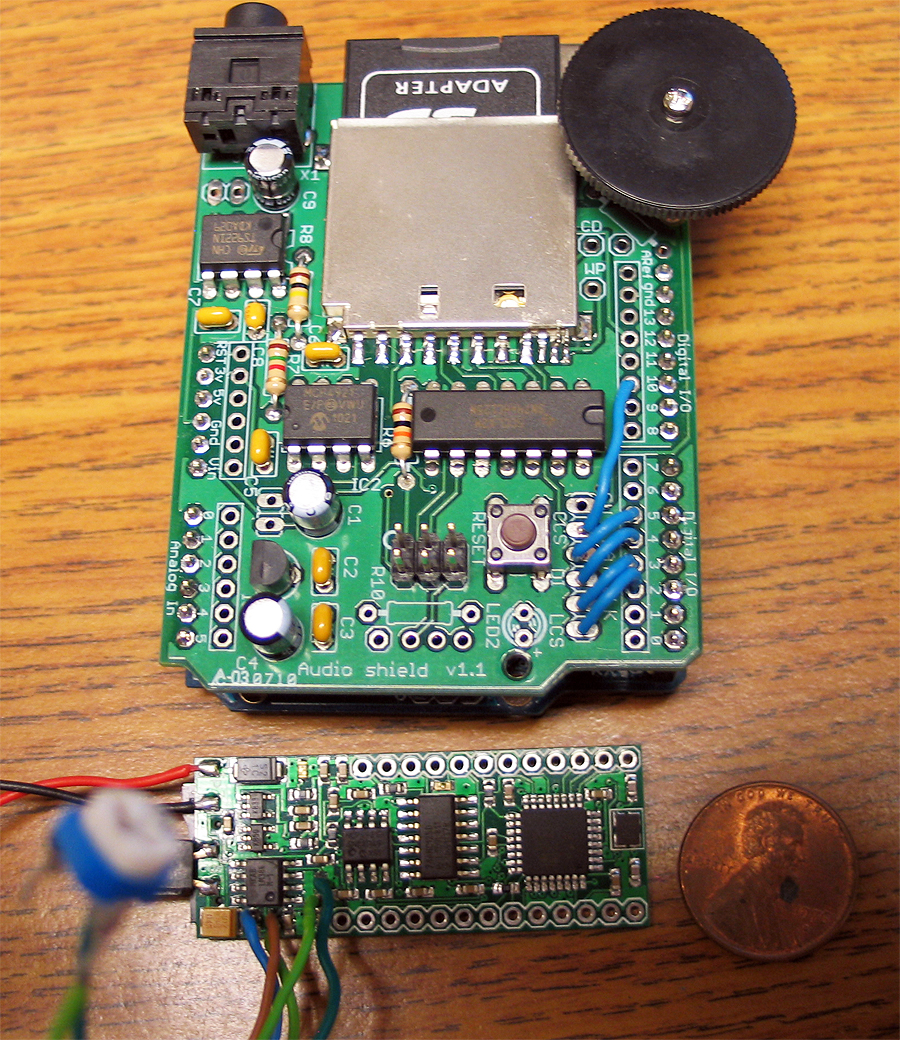

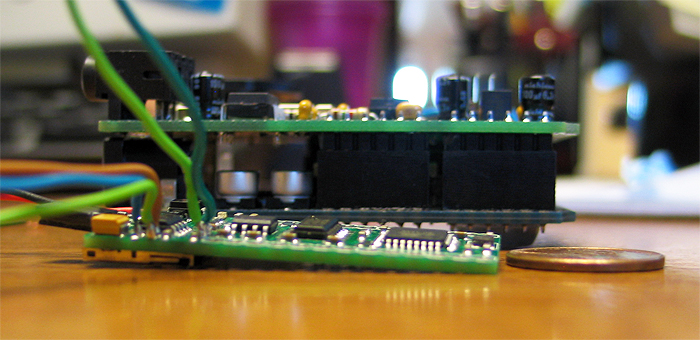

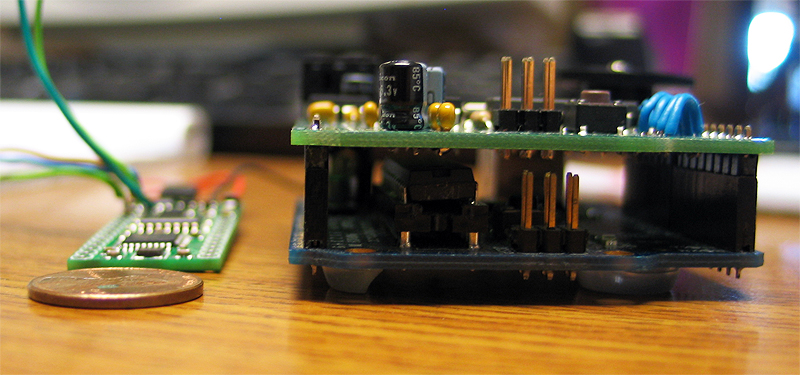

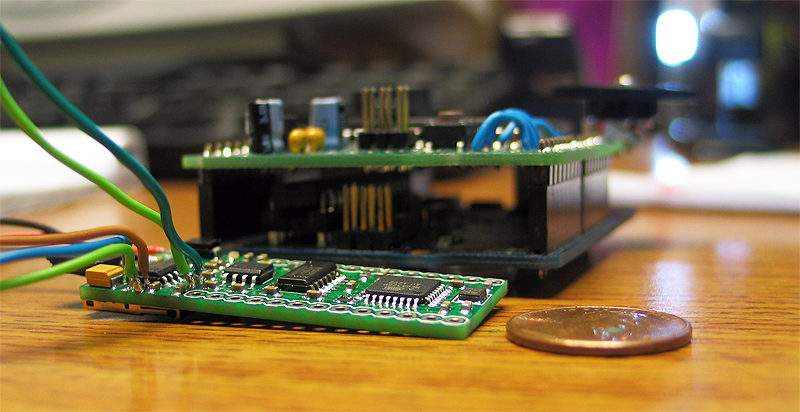

here it is on the left next to an Arduino board (with a WaveShield stacked on top of it for comparison)

(fonts changeable on SD card, reads/loads a few defaults off a text file on SD card as well to set a few parameters on the blaster)

*safety = if on.. you need to have the trigger pressed when you boot up

*maxammo = total ammo count before having to reload

*acolor = led color when in auto-fire mode (can be r, b, or g)

*acolor = led color when in semi/manual fire mode (can be r, b, or g)

here is the first video of stage/phase one of the electronics and code development stage of it:

Prepping the nerf gun: (in no particular order)

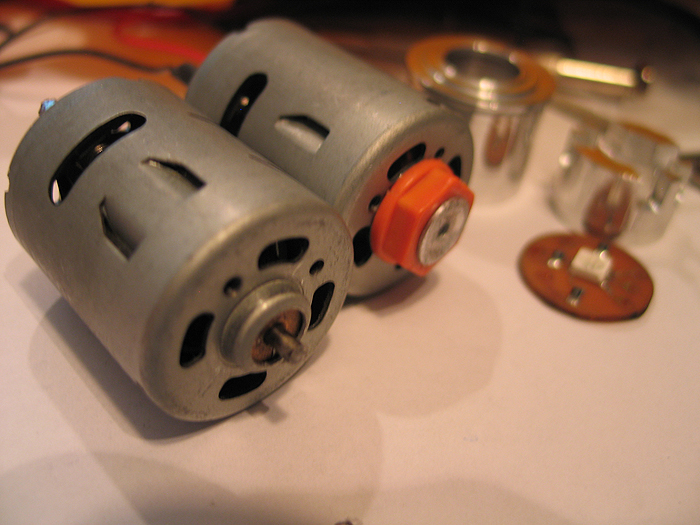

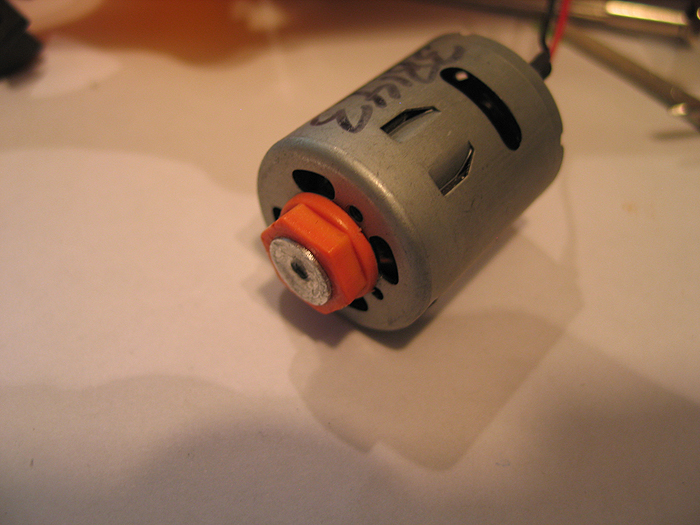

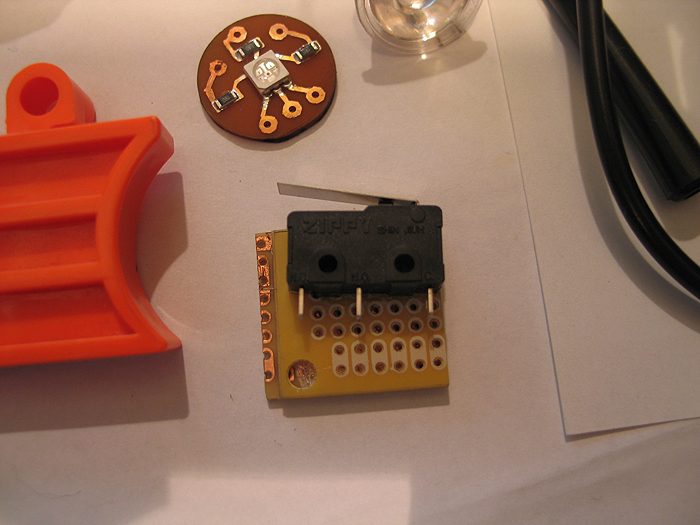

*I needed a motor.. but didnt really know how I was gonna make it all work.. about torque on motors...sizes..etc..

got lucky and scored a motor that looked like it would fit from my local science surplus store.. biggest I could find that was small enough to still fit..lol (it seemed like it was MADE for the gun once I got it home)

*I knew I need to somehow get some leds into the barrel.. and wanted to have it be RGB..

*Wanted it to reload by pulling the slide on top back

*Since its a blaster the SD card and batteries needed to be accessible without having to open the the gun up (ie: accessible sd card and re-charge port)

*Needed to account for a switch/button to switch from semi/manual firing mode to auto-firing mode

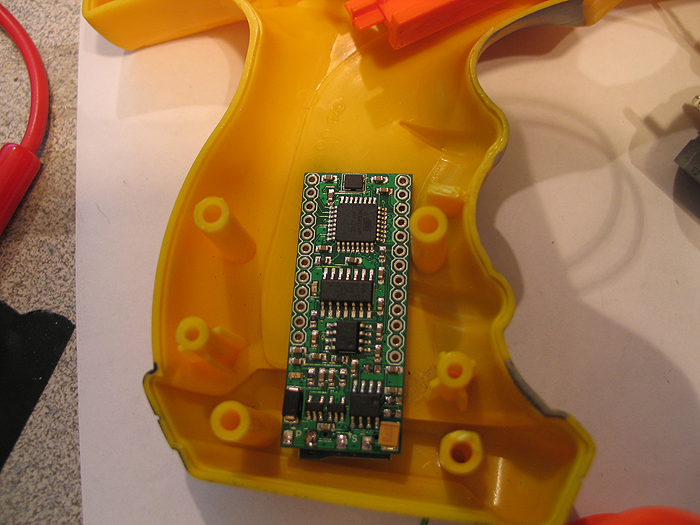

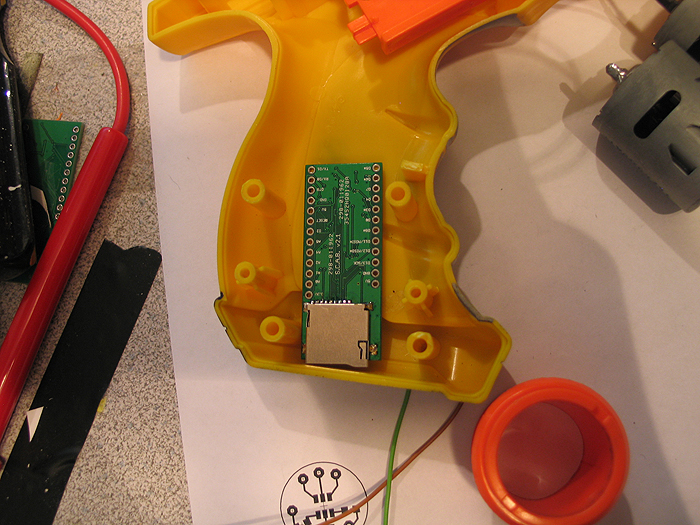

here was my first mock up for testing space and how I was gonna attempt things: (pre dynamic default loading)

(s.c.a.b. in grip/butt)

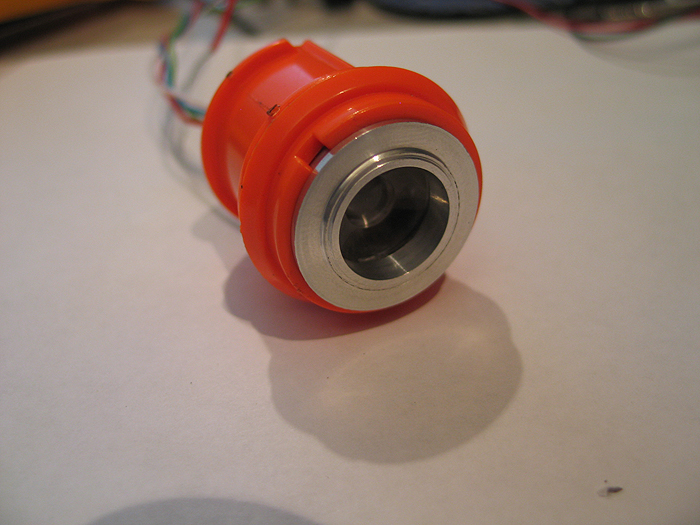

motor:

after taking apart the Maverick gun (many tutorials all over on it if needed).. I saw how the barrel was turned internally by trigger pull.. and figured Id hack/modify it to suit my needs.

I cut/sanded the hexed shaped top off the post/part that connected to the barrel and turned a little inner sleeve and press fit hole so it would attach to the cut down motor shaft.

before/after motors:

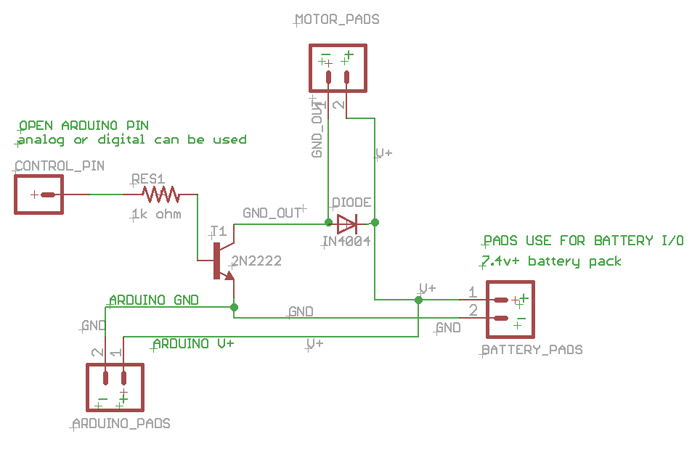

** what you dont see pictured is any pics of the custom PCB I etched for the components to drive the motor (SCAB/Arduino do not have enough power itself to drive high power devices.. so you need a driver/transistor...etc.. something to help out)

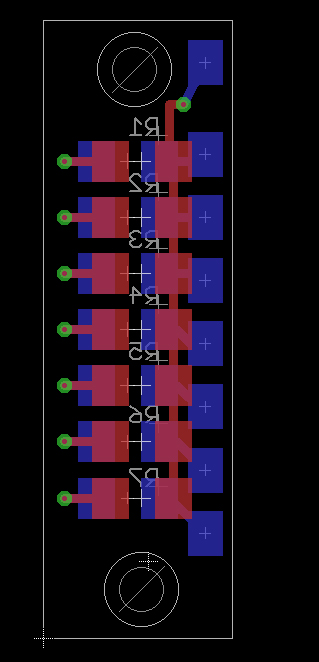

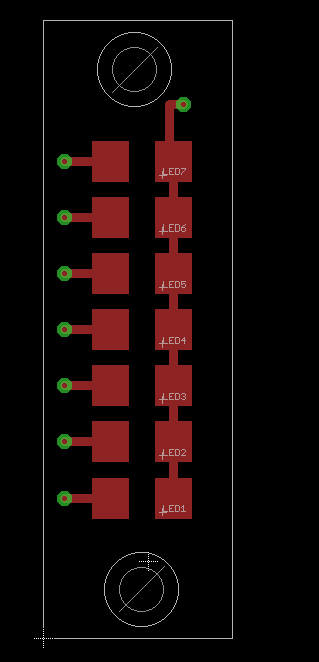

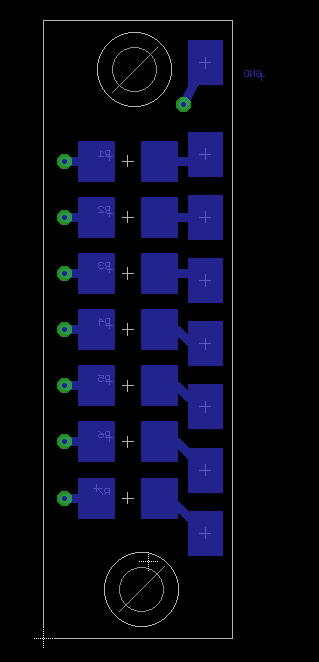

but here are the shcematic and pcb files I made in eagle for it:

[img width=568 height=768]http://dmstudios.net/misc/motor_pcb/motor_pcb_2.jpg" />

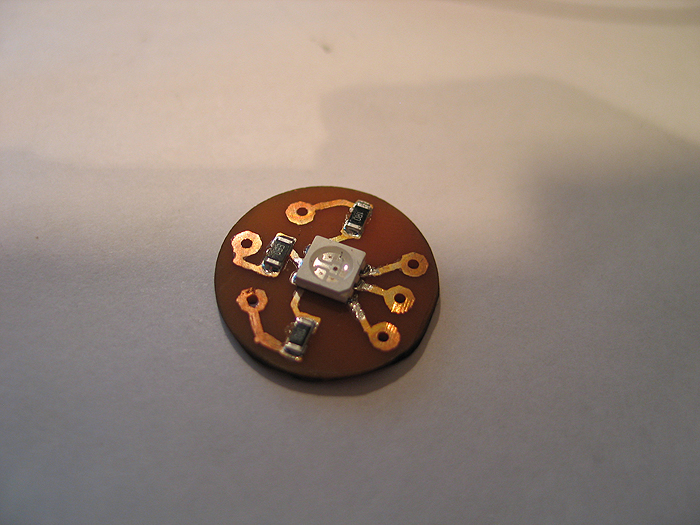

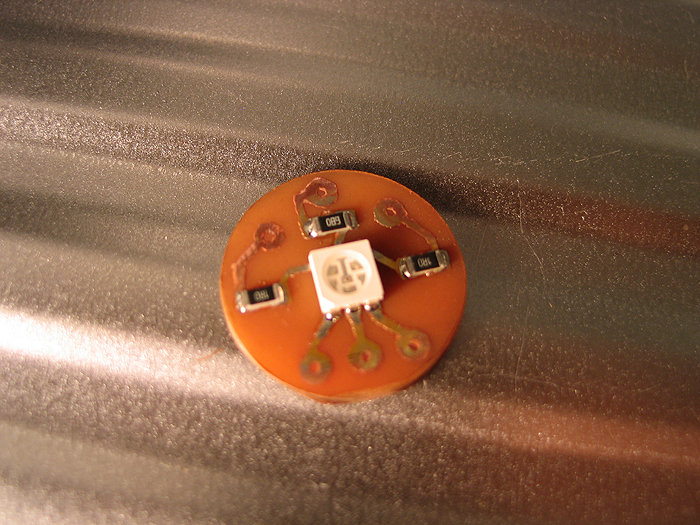

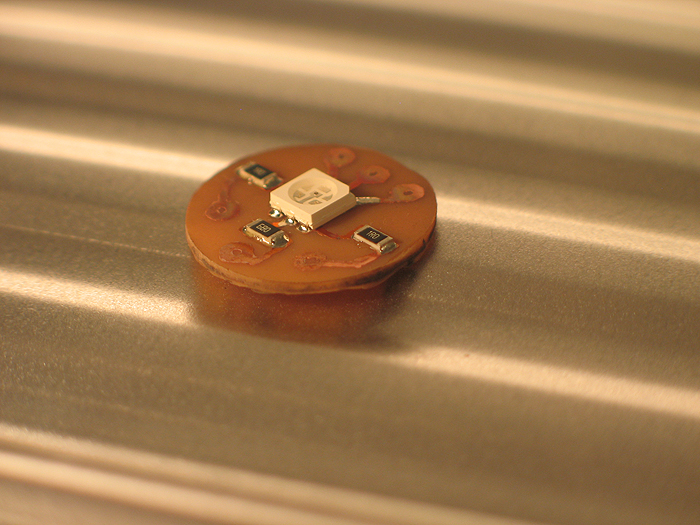

RGB barrel LED:

I was going to use a DX RGB led star I had laying around.. but then decided it was over kill for a blaster (not like I need to light up a poly tube/blade or anything)..

so I opted for a 505 RGB led,.

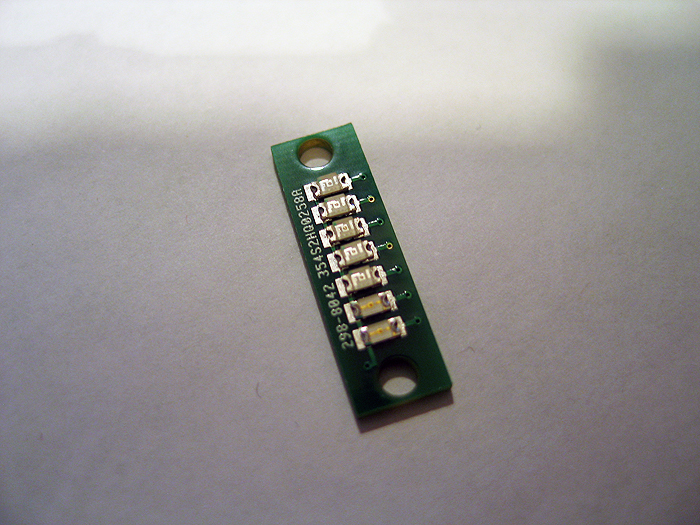

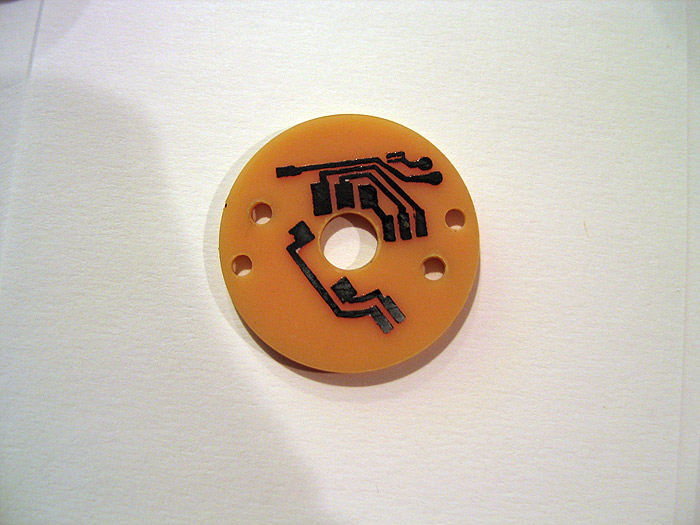

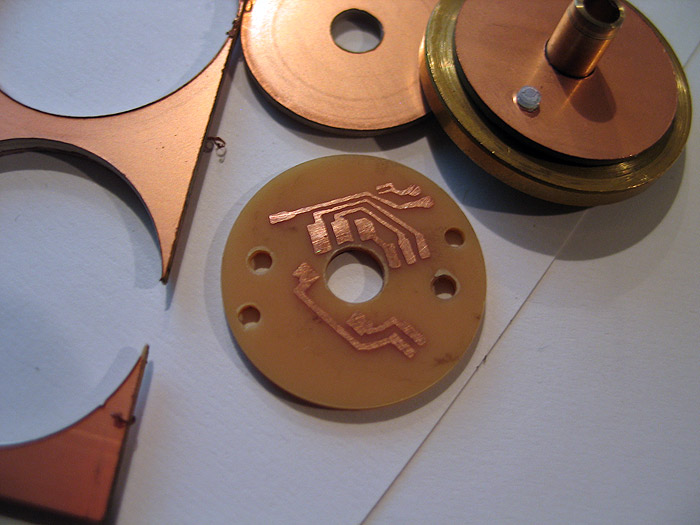

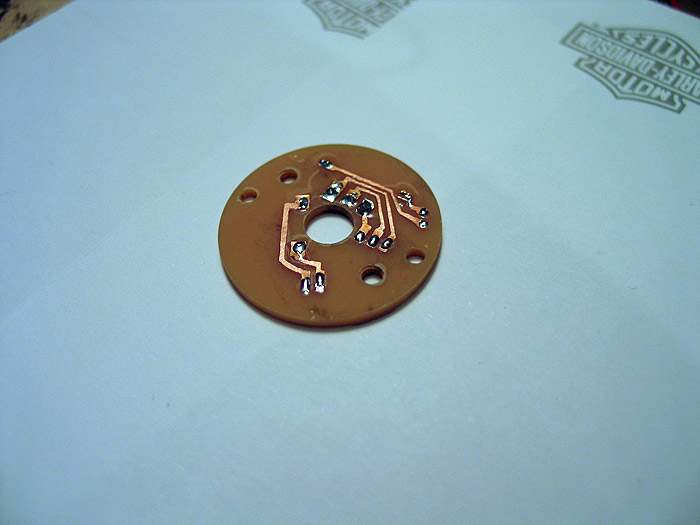

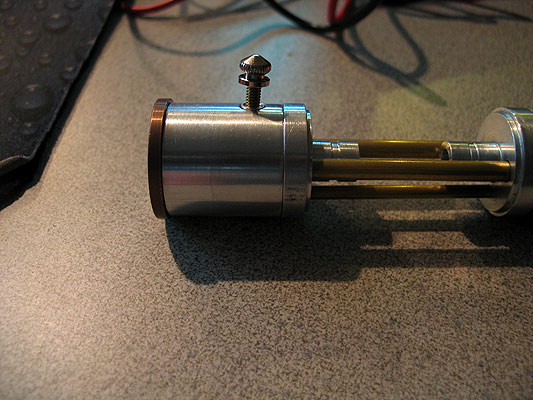

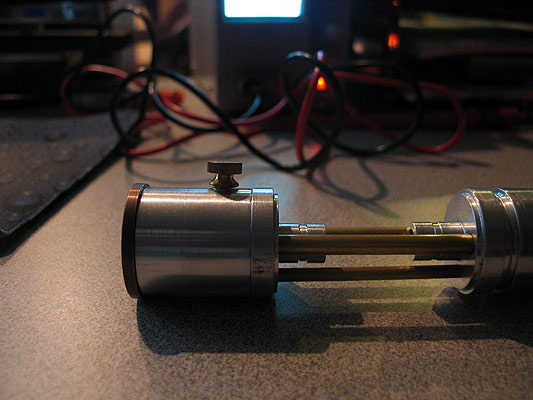

*created a custom home etched pcb for it

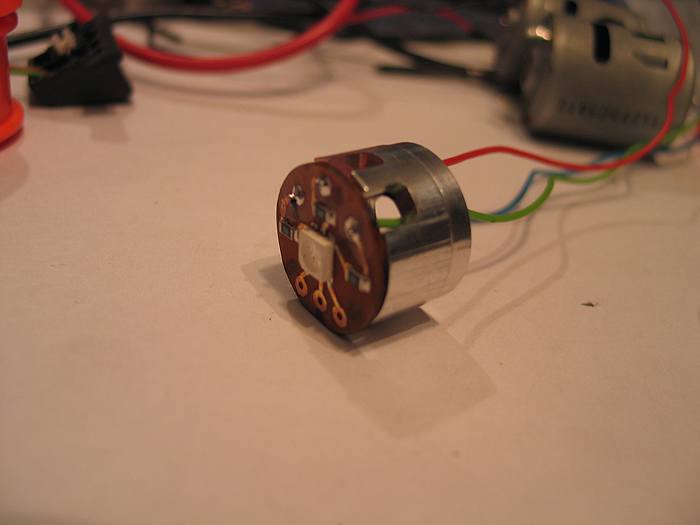

*turned down a two piece optics holder and pcb 'presser up againster' unit to hold everything.. (similar to Ace's small OD optics/holders... but mine are much more shitty and crude..and no threading....well you get the point).. haha..

I wont go into detail on how I etched.. I have posted a few tutorials stp-by-step on how to make these at home in 10 minutes enough..

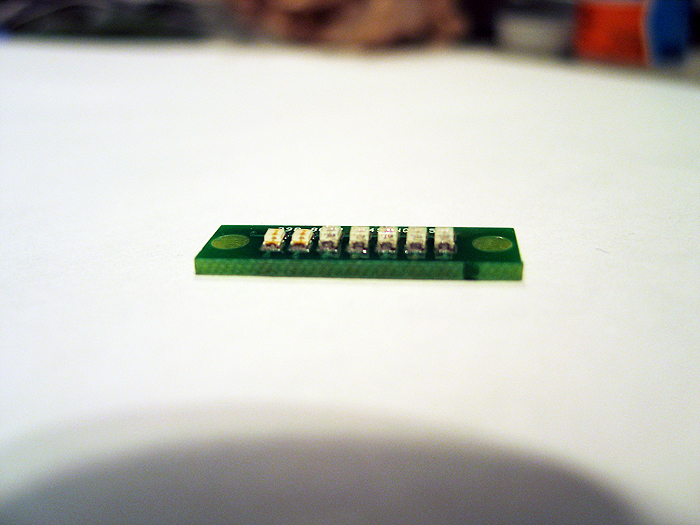

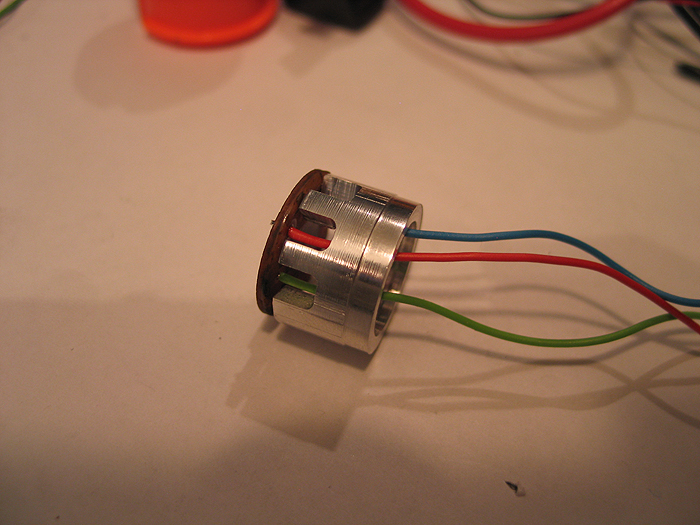

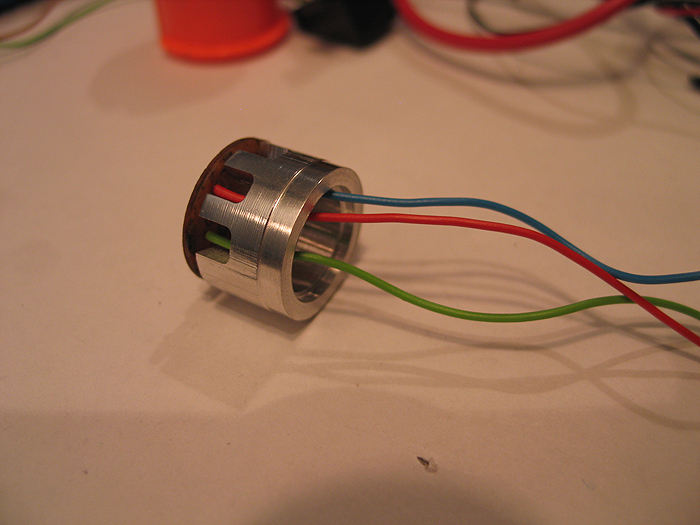

after etching.. smear some solder paste.. and populate board with resistors & 505 RGB:

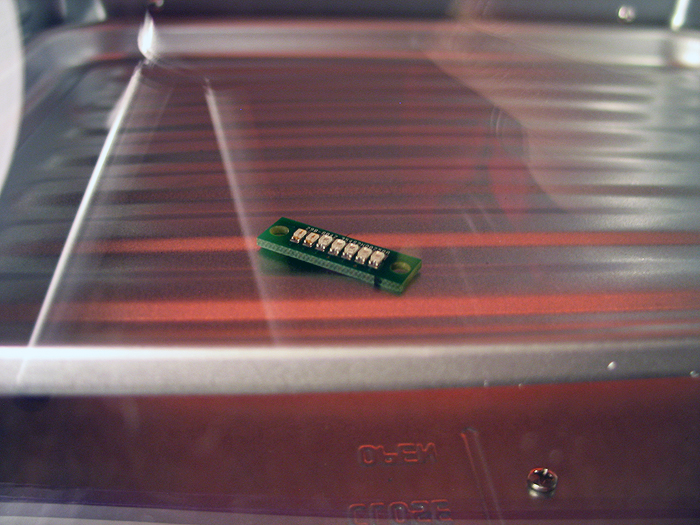

bake it in toaster oven:

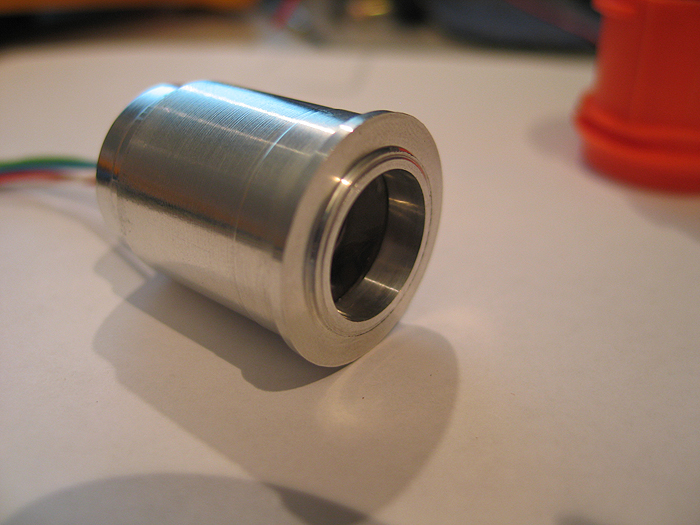

make inner sleeve/bottom portion to hold/push the pcb with (incuding some milled out section for wire passing)

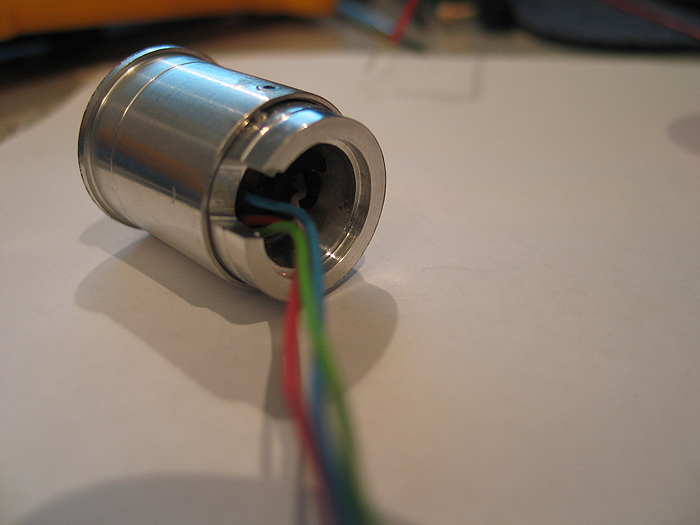

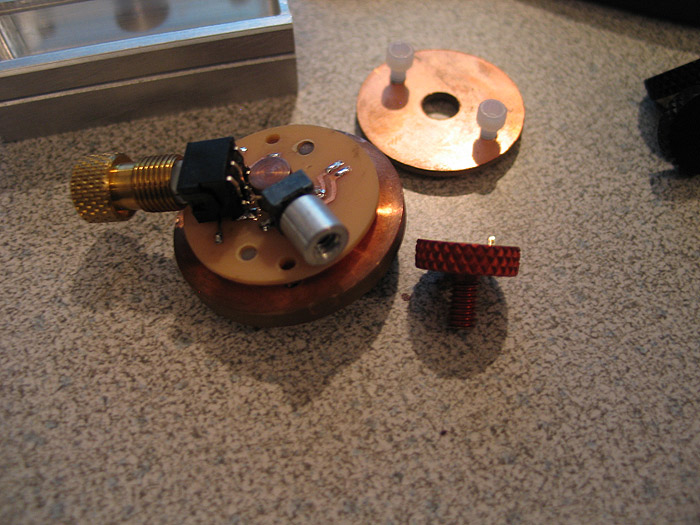

make outter sleeve to hold optics in it.. and also has the bottom portion slide in and sandwhich the pcb up against the optics......and fits in the Maverick gun plastic barrel part:

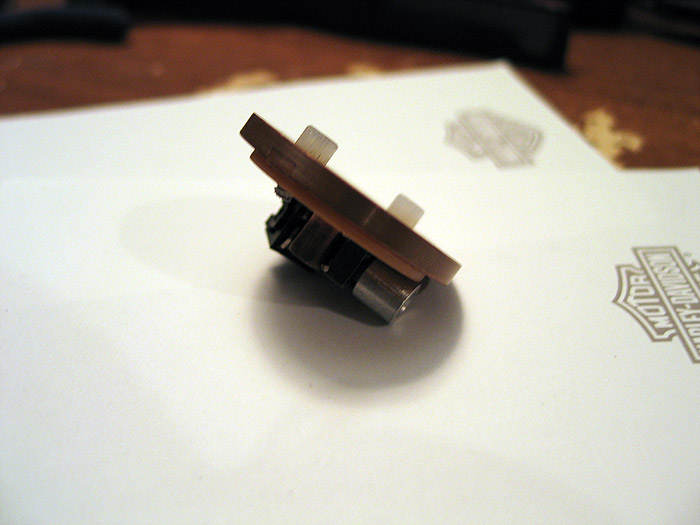

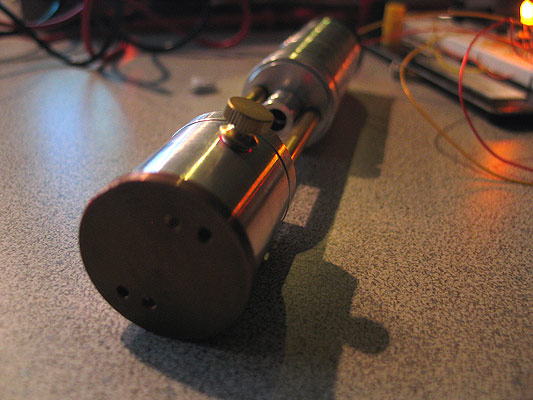

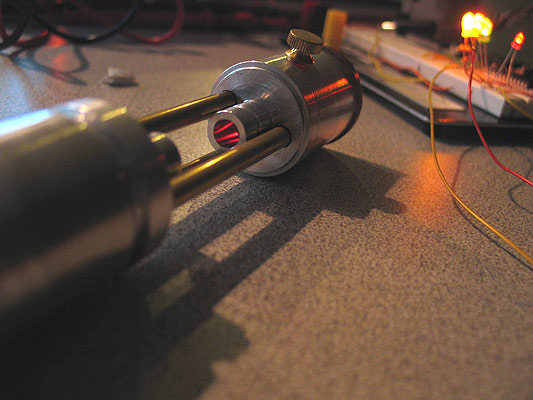

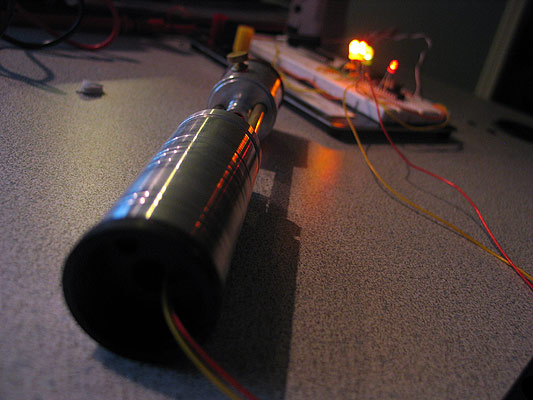

Unit all put together:

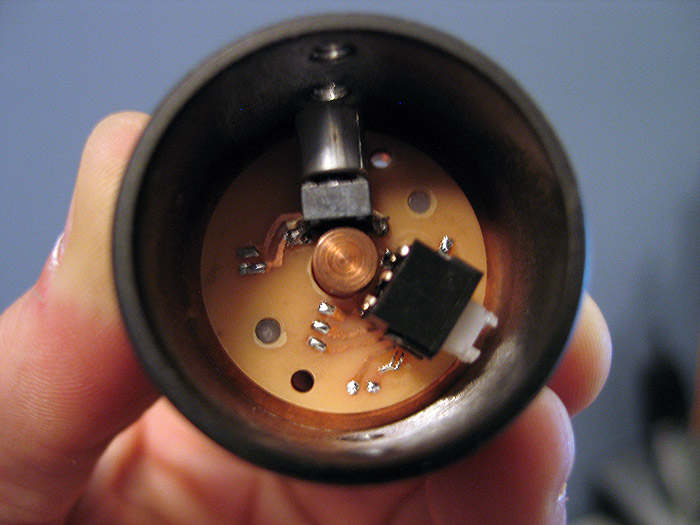

Inside the Maverick barrel:

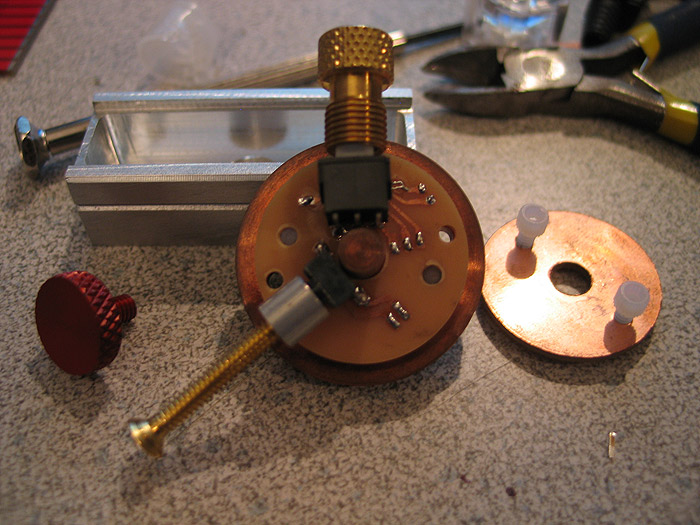

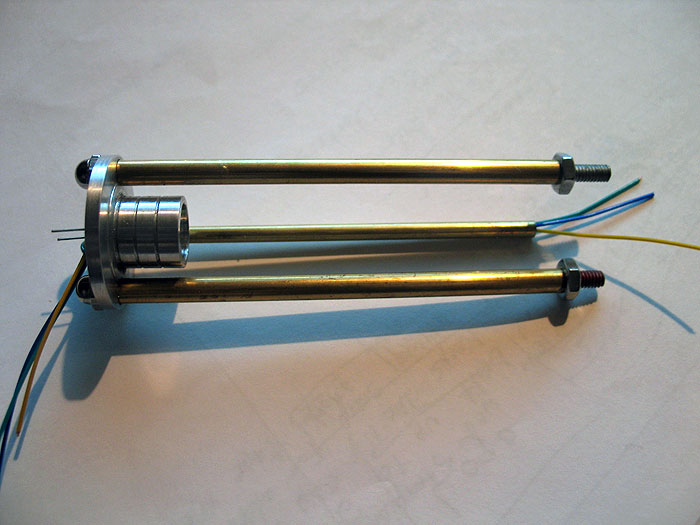

Exploded view of all parts/optics/pcb..etc:

Switches:

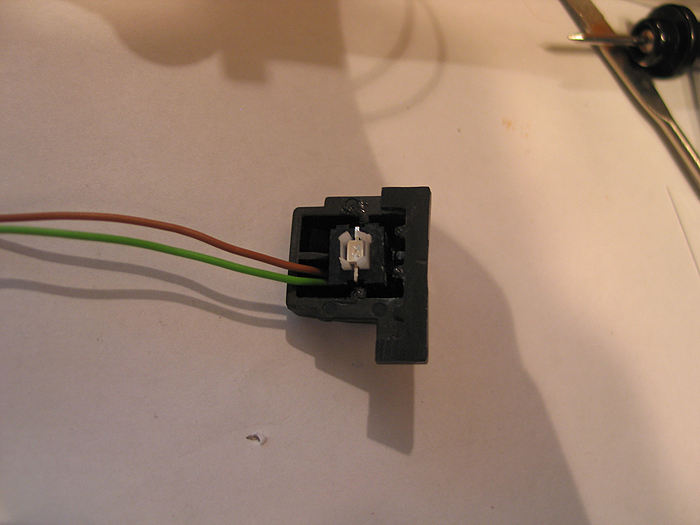

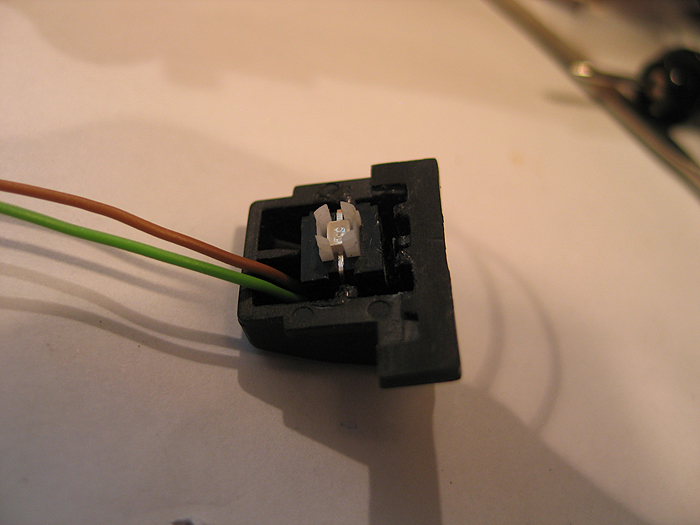

Mode select switch.. had to think about where I was gonna put this.. without some huge, ugly slider switch somewhere.. that looked like an after-thought...

I eventually decided to re-purpose the same button/area that used to allow the barrel to swing out and reload the darts..

*(this switch has an led in it.. I am nto currently using it.. but could be used to have the switch backlit.. I have a 3.3v pad on the board)

using a simple lever switch.. for both both main trigger and reload..

reload switch:

this one is secured to some perfboard cut to snug fit for inside the gun area.. it positions it in the correct place so the top slide hits it when pulled back, w/o mod to the top slide area/parts

main trigger:

you can see where I placed it int he above overview shot of the gun layout..

I mod'd/filed down the trigger a bit to hold the lever from the switch it in easier...(works great!)

after getting all this work and aligning things up.. I did a quick mock-up and cram-fu test with it mostly assembled.. (some parts have to wait for final paint and/or assembly)..

I took this video of its current state.. which Im calling 'done'.. and ready for break down and final paint & weathering (attempts) lol

thanks for the poll/feedback..

Im still not sure about trying a chrome/silver/nickle base and some dark washes.. or going with a black base..and trying to silver/grey dry brushing..etc.

(better decide soon eh?) lol

:005:

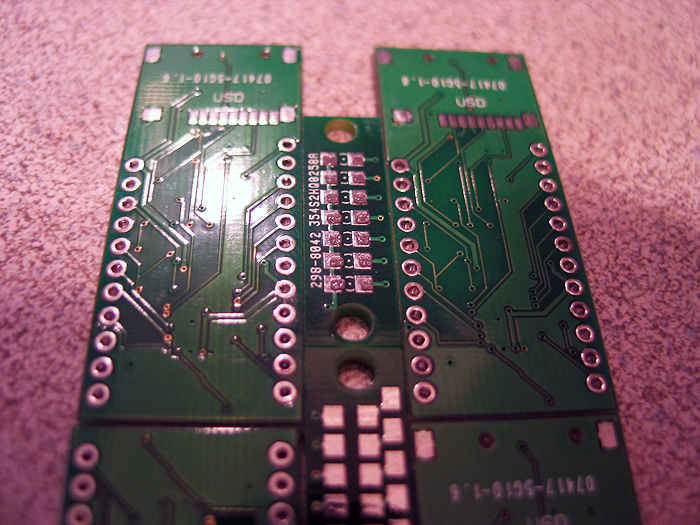

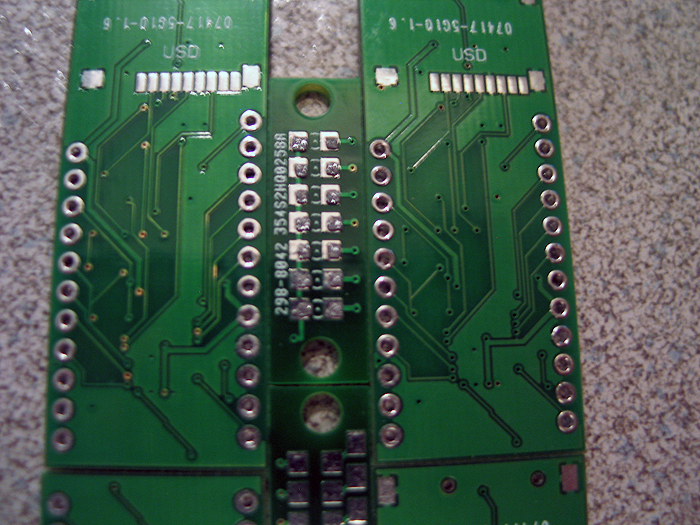

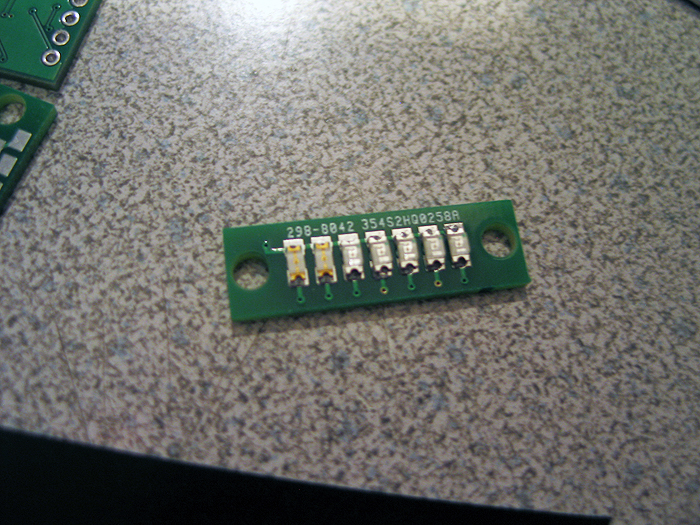

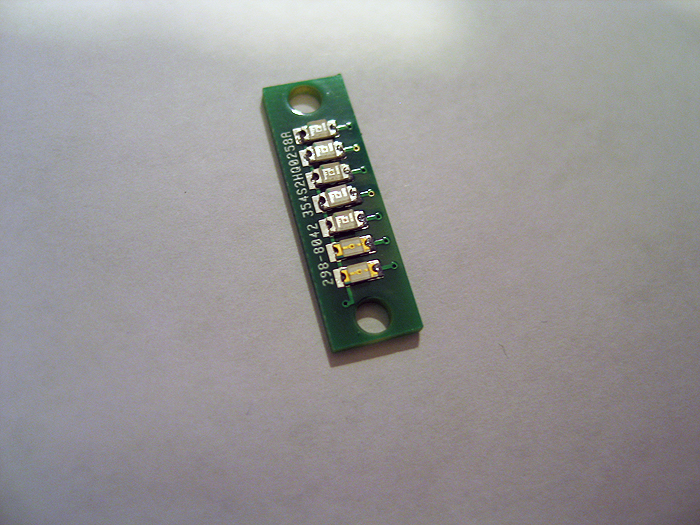

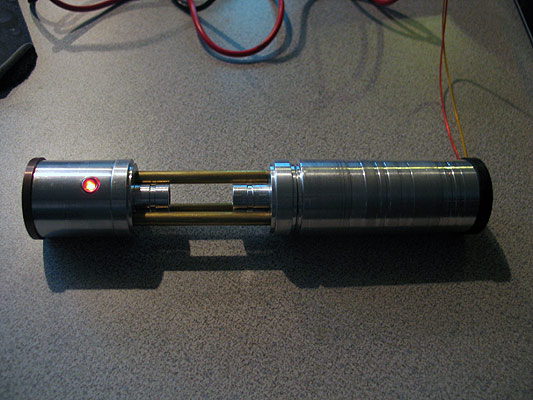

PoC: Custom MHS heatsink pcb (for my Obi TPM)

was going to post this in the 'idea thread'.. but figured just make its own thread for it..

another step in my OBI TPM saga.. lol

trying to keep the size as accurate as 'I' can, and still having it be somewhat MHS based at the core...

I was stuck on finding out a way to use the stock switches as real, functioning switches for my hilt.

(Ive always been keen on the all-in-one core ideas... but have the switches on/in the core and some sort of cap/plunger on the outside has always been a PITA for me... here and there a few ideas have came out/been used)

for the OBI.. when everything was done,.. the switch holes would go (more or less) at the same exact level of the MHS heatsink.. so I need to adjust that a bit.. and also find a way to mount some switches in that area..

I had mulled over Madcows switch approach. but just wasnt a good fit..

so I came up with a custom, round PCB, that mounts to the underside of the heatsink..and is secured using the same nylon screws that hold our luxeon star pcbs. (MHS hack!)

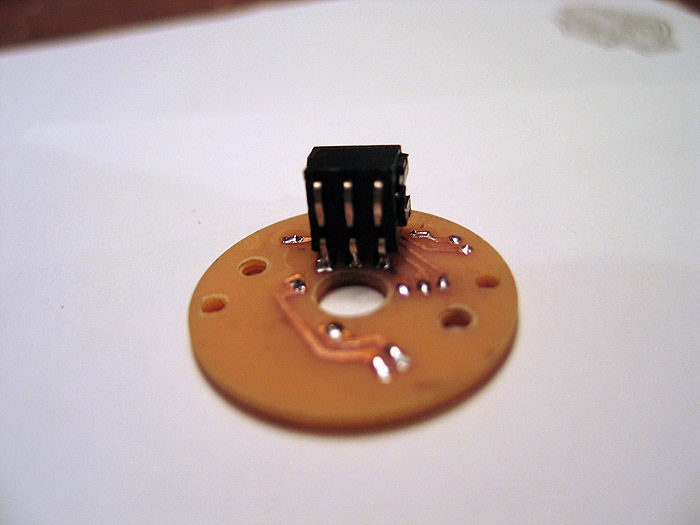

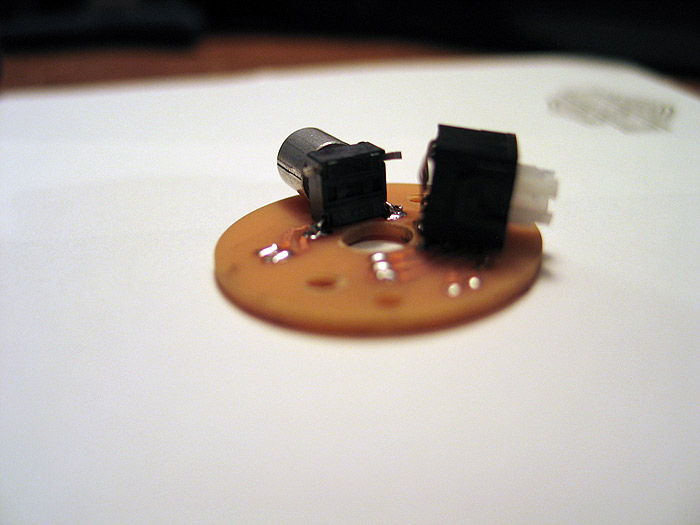

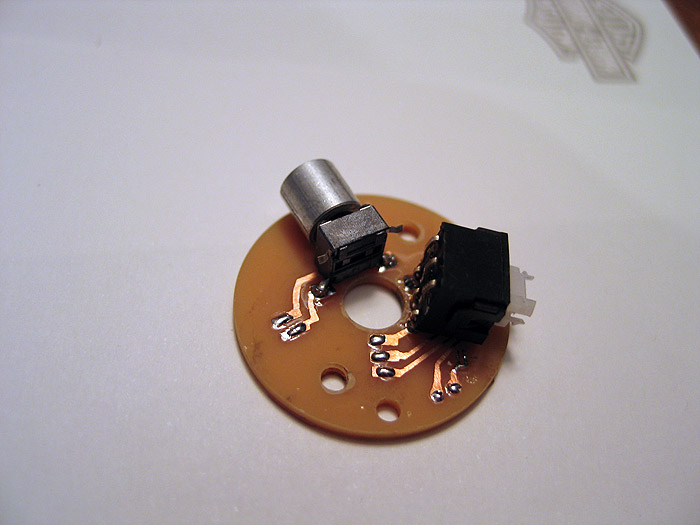

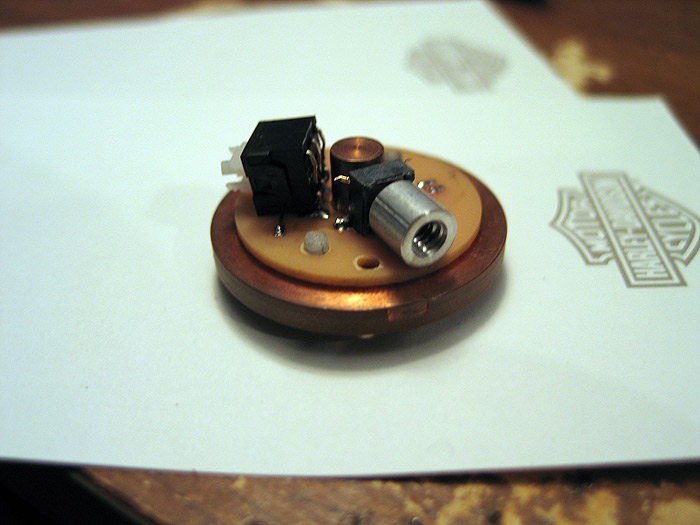

here is my prototype..

the bike valve switch will have an SMD led in it.. (like they normally do).. to light up the purple gem in the valve end. I just didnt put it back in yet..from doing the momentary mod to the switch (latching by default)

I also didnt clip the extra leads from the switches yet.. but I believe the idea is sound.. and can open up the doors for others to use the same idea/approach.. (nned to mount a unique switch?.. make a pcb for it!)

I posted a tut on how to etch your own pcbs..etc.. using your home laser printer and photopaper..

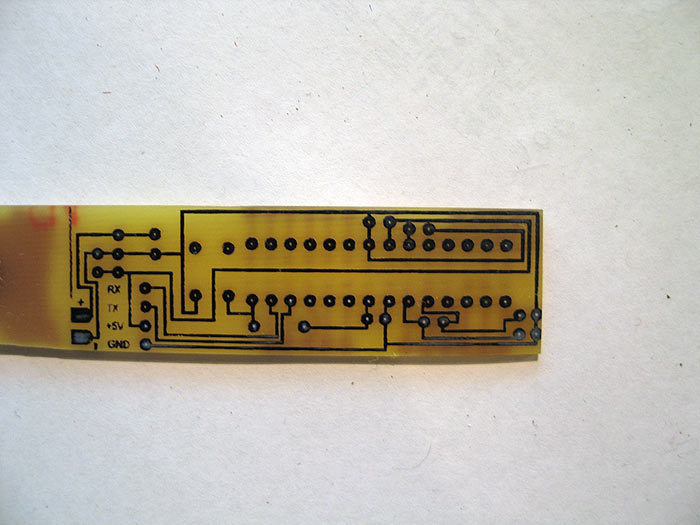

1.) make pcb deisgn in photoshop..

2.) print to photo paper

3.) iron to your copper clad board.

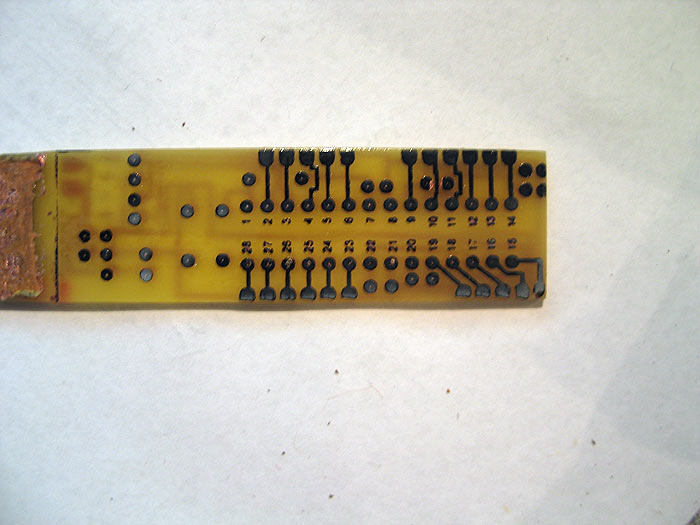

you get this:

etch and you are left with your laser printer traces (covering the copper underneath)

remove toner: (pcb is left)

Like Erv taught us.. pre-tin folks!

bend my switch leads underneath..and the other row down:

other switch:

on heatsink:

I dont have a red thumbscrew with the correct threads yet.. but you can see it mocked up there.. (screws right in from outside of hilt)

when heatsink is in MHS part.. it lines up with the holes perfectly.. (cant see it so good in pic_ =(

feedback always welcome..

hope this helps others get past road blocks in their projects!

thanks

The Jeruino (Arduino compatible clone circuit)

Introducing the Jeruino! (not really.. but everyone else names their Arduino knock-off clone circuit.. figured I might as well be trendy too!) LOL =)

Everyone knows how much of a whore I am for the RFX platform...

I have also been playing with the Arduino for a while too... (any member here or JSSDC can easily jump in..with both feet and be up speed (at least my speed) in a day or so...so I dont wanna hear any pissin' & moanin' about things being too hard.. lazy I'll accept)

a HUGE problem for everyone who posts this junk is 'footprint' going from the non-practical BREADBOARD set-up that is great for YouTube vids.. but not so great for any practical project.. nor is stuffing a 'real/true' Arduino board into a project (they are more development/prototyping and have alot of bells and whistles you dont need in the end) very practical and wastes money.

you can get all the components for a barebones Arduino for around $7 bucks or so.... which is much better than $30+ each time to shove in a stunt or costume or other prop..

I saw Alec post his jedi training remote.. and pm'd him saying that is great project for an RFX or Arduino 'brain'.... since it doesnt need a CF or PC..etc.. this little brains fill a nice niche.

So I opened up photoshop and got to work on making [u]my[/u] first 'real' pcb schematic (IMHO).. since this was a real working board..and not just some traces to hold sensors or switches as I have etched out before..

(I etched another 'real' board...but it was based on TroyO's schematics for a multi-channel LED driver board.. which I've posted before...PWM chopper type)

this one I created myself from scratch.. and google/instructables... (basically ported my breadboard Arduino circuit to a PCB) with the intent being fore Alec's jedi training remote.. (anyways.. not sure if that currently being worked anymore) =(

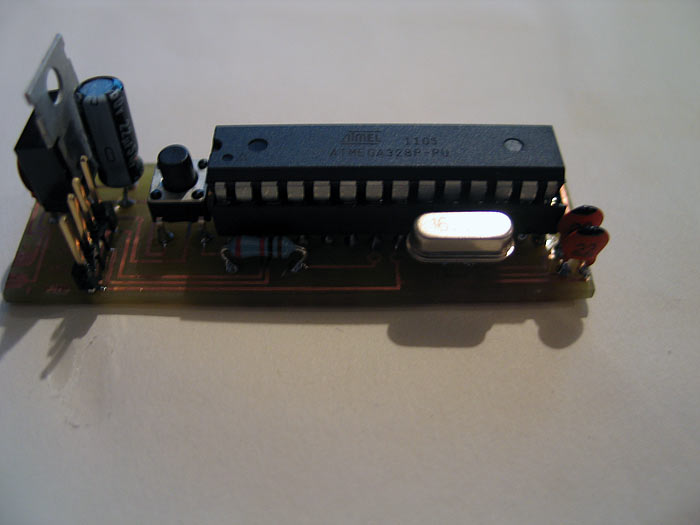

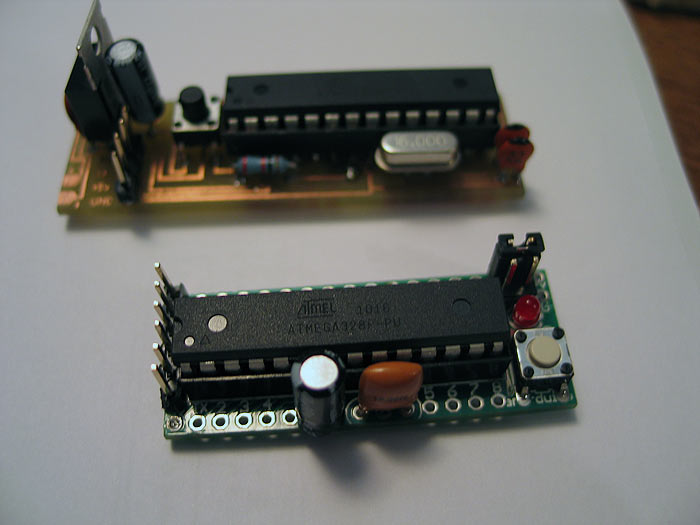

but I produced my first functioning Jeruino board.. ![]() (Arduino clone)

(Arduino clone)

Its no PlecterLabs, professionally design PCB.. etched by a PCB house...etc.. this is DIY at home... (so if your looking for that.. Alt+F4 is for you! =) )

anyways.. on with the story/post.. =)

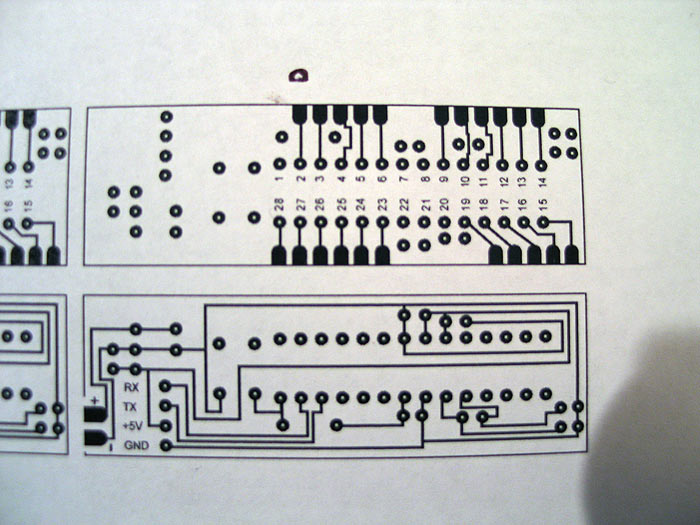

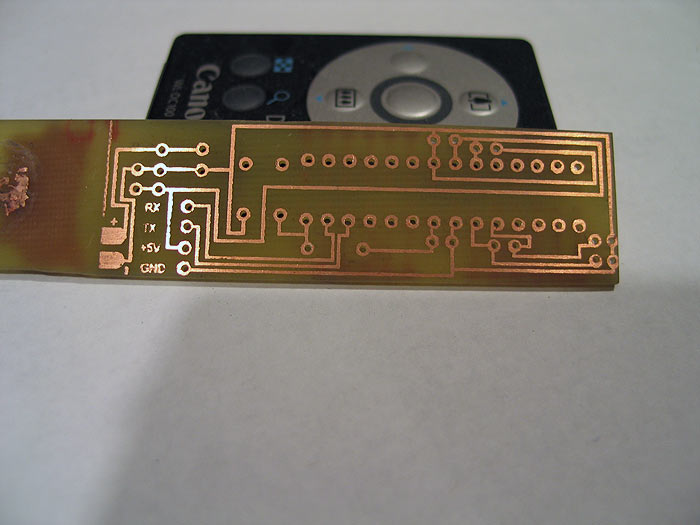

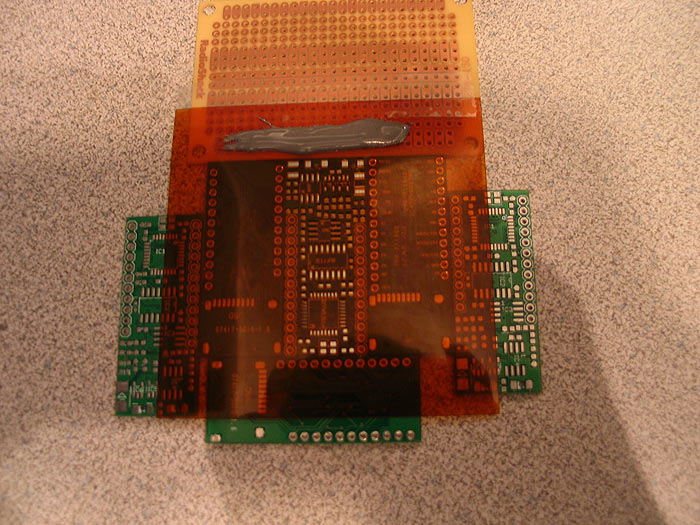

SO I made a design in Photoshop to illustrate my traces and vias/pads..etc

you print this out on GLOSSY PHOTOPAPER.. done with a LASER PRINTER (not ink jet)

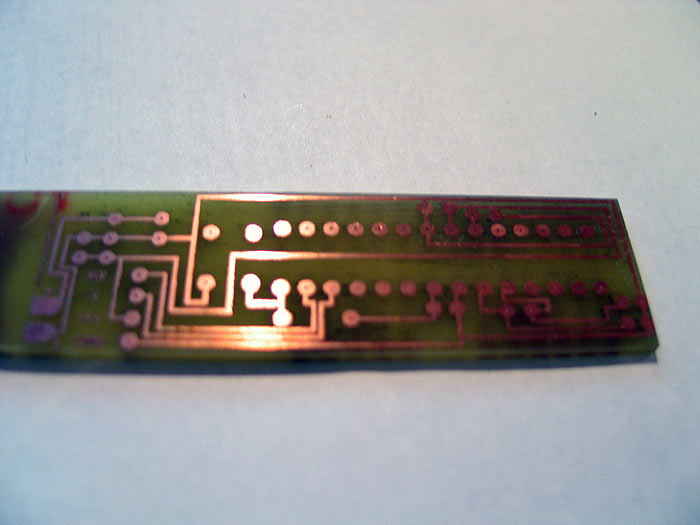

**this happens to be DUAL sided (avoid at all costs if you can..true PITA for DIY)

you cut out your traces/design... lay it over your copper clad board (RadioShack..or anywhere)

and you IRON it.. heating up the toner so it adheres and transfers to the copper board.

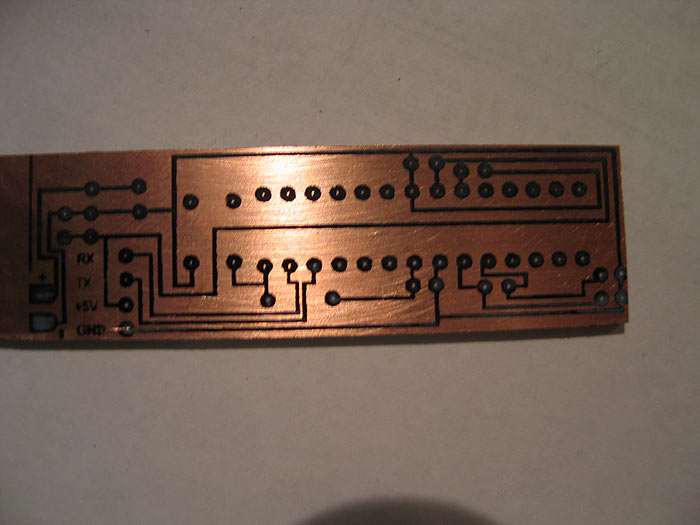

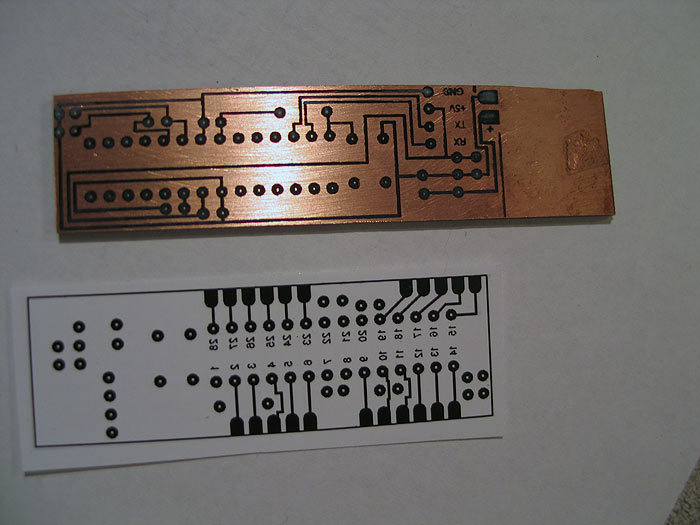

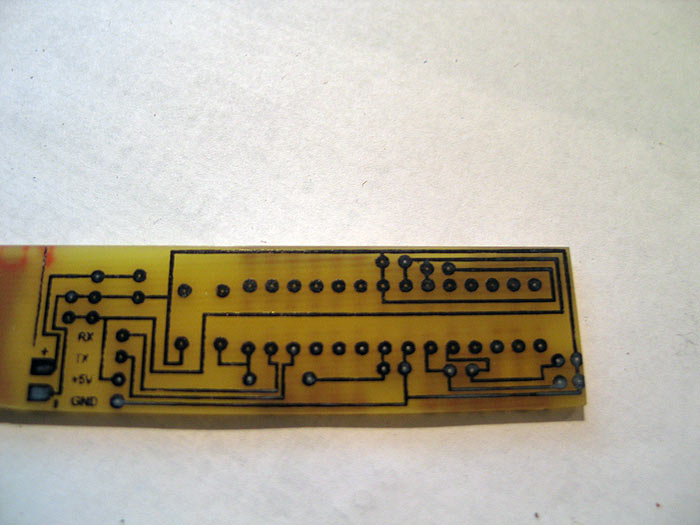

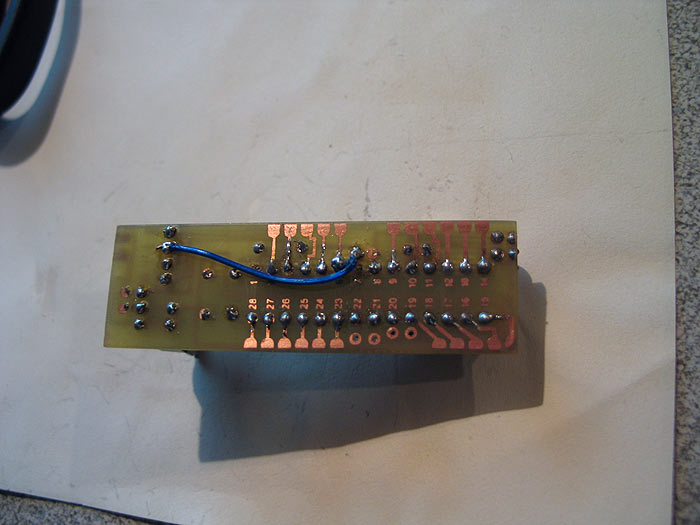

let sit for a few minutes.. run it under water.. and rub/peel the paper away under only traces are left on your copper board: (looks like you printed on the board... sometimes traces by the edges do NOT transfer good.. so be careful.)

cut out other side.. and get ready to repeat process:

once you have your traces transferred to the board.. it is time you etch away the visible copper.

All copper is gone.. leaving only the traces you transferred to the board left.

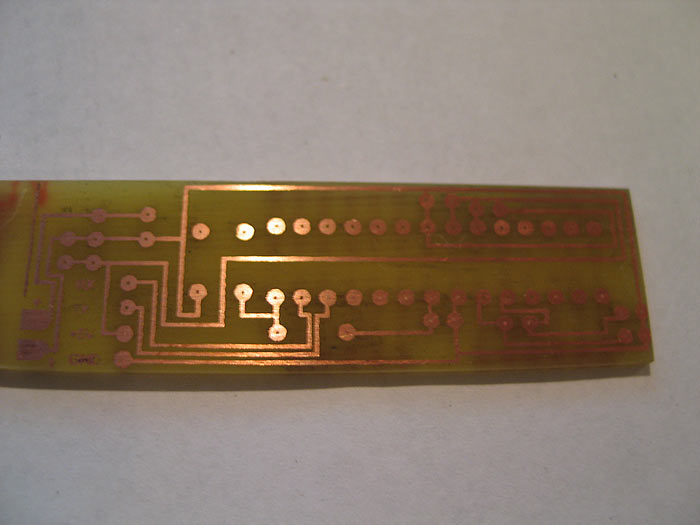

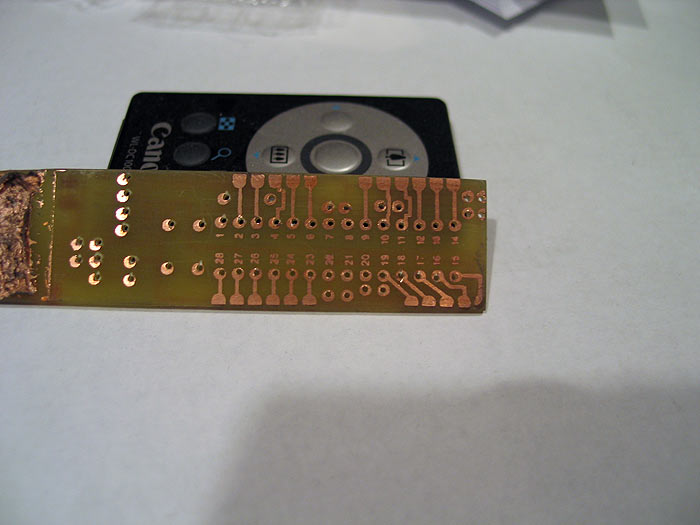

the flip side: (**warning..UGLY.. you can see the lift of the paper and traces that are crummy on this side) (you can see the holes mis-aligned a bit.. but no worries..all good)

this side came out pretty damn good though:

from here.. I removed the toner on the board with some ACETONE..

Next we drill the holes (damn there was a lot)

Doesnt look too bad (from the top)..LOL

clearer view of the bottom side with some mis-aligned holes:

what stinks about the DIY approach with dual sided.. is THERE ARE NO THROUGH HOLES PLATED.. so its a real BITCH to solder through the holes to bridge continuity..

Anyways.. once you are at this point..

you can start to solder on your components:

and....viola`

and finished product..

threw in a Atmel chip from my Arduino.. (already had a sketch/program on it..so I knew it was working)..

powered it up.. BAM.. it worked! (STOKED!)..

however.. before I posted.. I needed to check the FTDI headers.. (these 4 pin headers are how you talk and upload new sketches/programs to the chip to be 'run')...

[b][size=150]FAIL![/size][/b]

it runs...works.. but only a pre-programmed sketch that was/is on the chip.. (BOOOO!)..

who wants to buy a REAL Arduino (besides people like me).. just to swap out the chip for your final project every time your done? (I guess many people do it this way though..as FTDI takes up a little space?)

be nice to just write directly to your final Jeruino.. ![]()

so after some BS and a few swear words.. I fixed everything..(ala Ultra Sound approach) LMAO...

found a few continuity problems from top-side of board to bottom side of board..

and an FTDI problem...

the Ultra Sound fix was a missing trace to a certain pin (pin7...VCC..yikes)..

so I had to use a fix wire..like the old US boards.. hahaha.. (throw-back)

(it looks worse in the pic)

and of course.. because no good deed go un-punished and hard work is always laughed at in life..

I got punished by NOT doing my due diligence.. doing all this hard work for NOTHING!..

as I found a KIT.. that does exactly what I just created from scratch, myself.. that is MUCH more easier, and much more professional (however you dont get the satisfaction of failing over and over, swearing alot....and its missing any kind of Voltage regulator.. but making a quick PCB for that would be no problem!!!! haha)..

so I got a kit to compare mine..to 'his'... (fucker.. I really like his kits!!)

so without further ado..

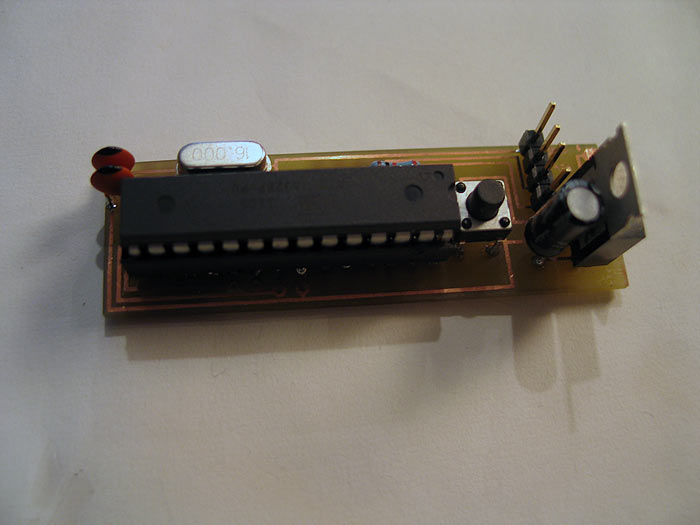

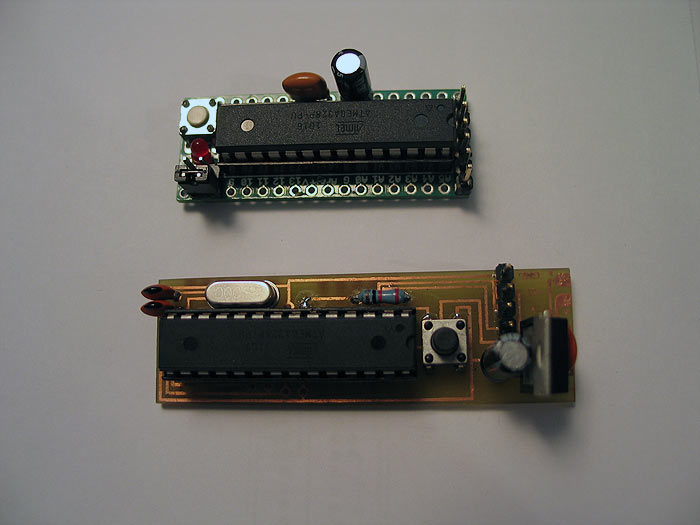

some compare pics:

my DIY vs purchased (mine has a vRegulator though..so its a bit longer)

**disclaimer-

I make no implications that I know what Im doing..

that this is the BEST approach

that this is absolutely how things much be done.

I am simply sharing what "I've" done...

but for extra $10.. it can really kick up a stunt or costume..

you have a BRAIN with MANY I/O ports to hook stuff up to..

LED's... servos/motors.. accelerometers... and the list goes on and on..

all the same brain.. just change the code. =)

hope this helps someone finish that special prop/project.

feedback or questions are appreciated.

Thanks gang..

S.C.A.B development…

Over the 'years'.. (since I was first turned on to the RFX project/platform).. I fell in love with the idea of a generic platform for the user use as they saw fit.

motors, leds, rfid...whatever the project was.. a nice, simple, generic platform for users to 'tweak' and customize seems like a great idea to me.

with RFX basically defunct/dead... I turned toward the Arduino platform. Had a huge following, lots of examples.. and quite easy to get up to speed on basics..etc.. (even without an electronics background)

The problem with the Arduino platform (as is).. is that its purpose (to me) is for developing/prototyping your projects.. but not to be used in the end application.

why? due to size.. and price mainly for me.. (although other Arduino variants can come in smaller sizes.. the price is includes extra development stuff you may not use in your final projects...etc... and not to mention a minimal Arduino circuit can be made for under $7.00 bucks!)

And getting an Arduino to play audio isnt done easily (by default)..

****(although now I just tested a super easy PWM based audio output library.. doesnt use any DAC or AMP.. and the quality is pretty decent for what it is!)

SO I began to teach myself Eagle.. (not easy for me unfortunately..but after some time I got more comfortable with it)..

and laid out some stuff.. and finally felt confident enough to start making my own PCB's and having the shipped to me.. (instead of the old DIY home brew etch approach)

So here I am documenting my process.. (and failures) along the way.. ![]()

a qcuik summary of the things I had to learn.do/involved..

*need to make a the schematic/circuit layout in Eagle

*hope its correct or have others look it over (check against design rules too)

*order the pcb's (sending the exported GERBER files form Eagle to your pcb fab house of choice)

*order a stencil (which is used to layover the pcb and smear solder paste over it to get it applied to the exposed pads through stencil)

*place parts on pcb (tweezers!!!!)

*re-flow pcb in oven

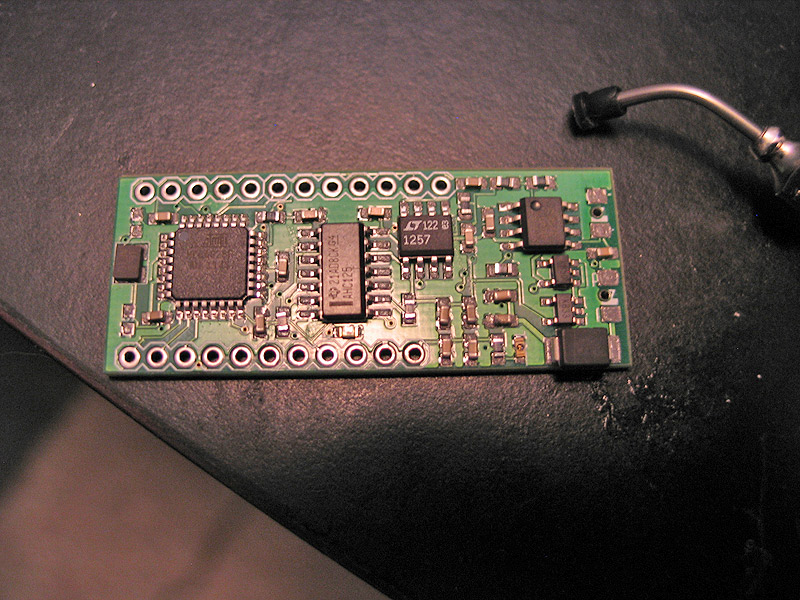

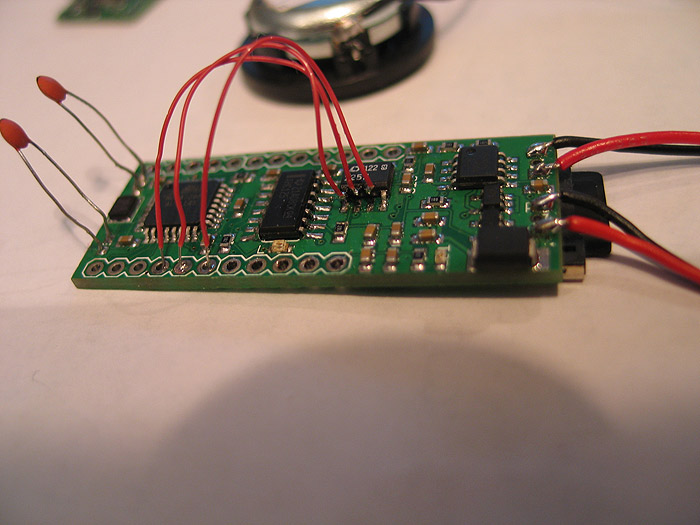

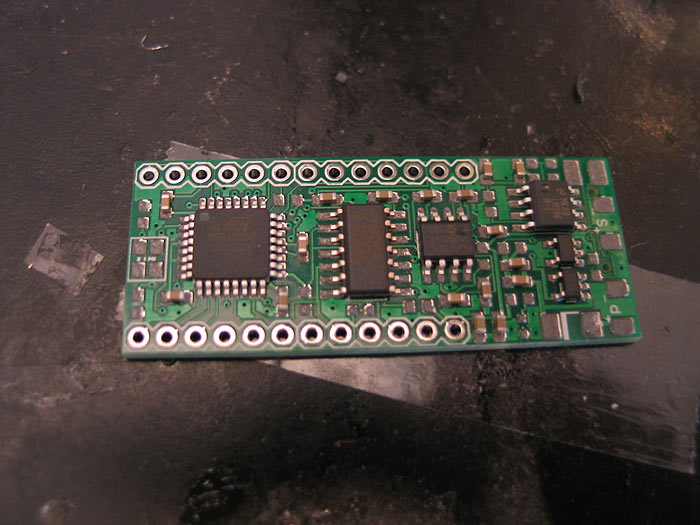

This was my first iteration.. using a different DAC than the schematic I was using as my guide:

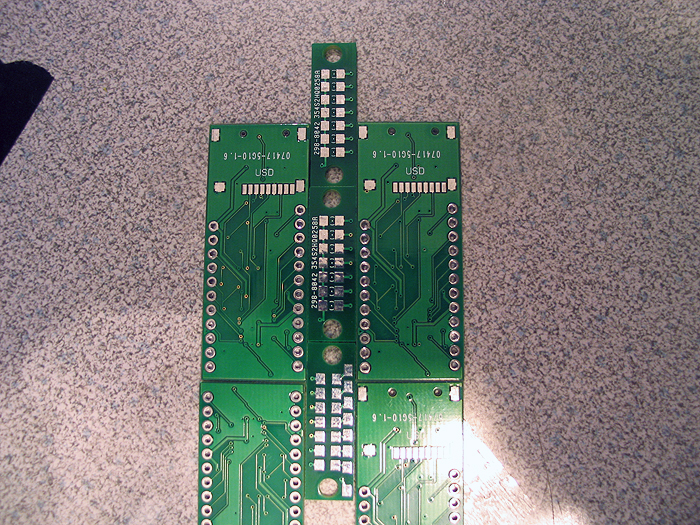

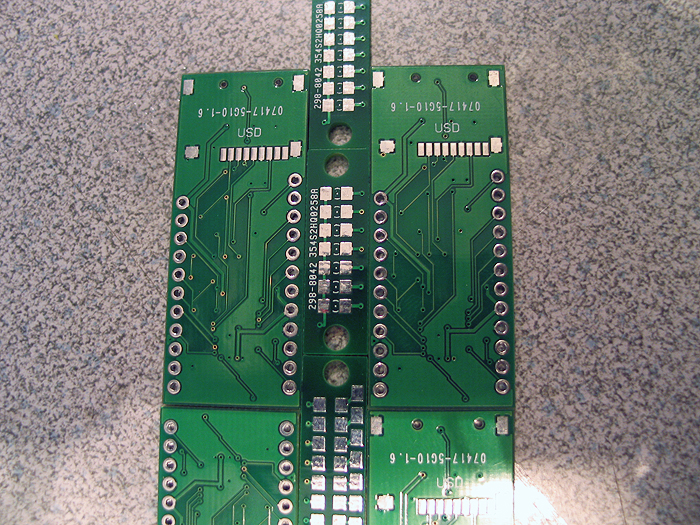

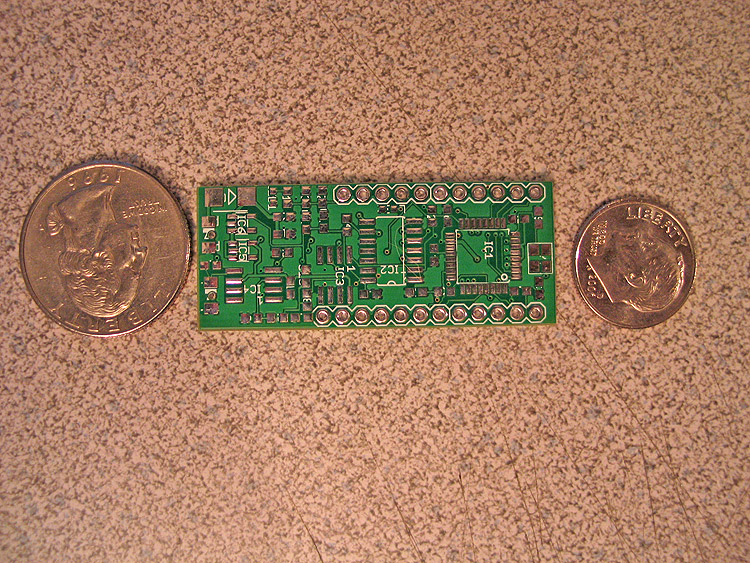

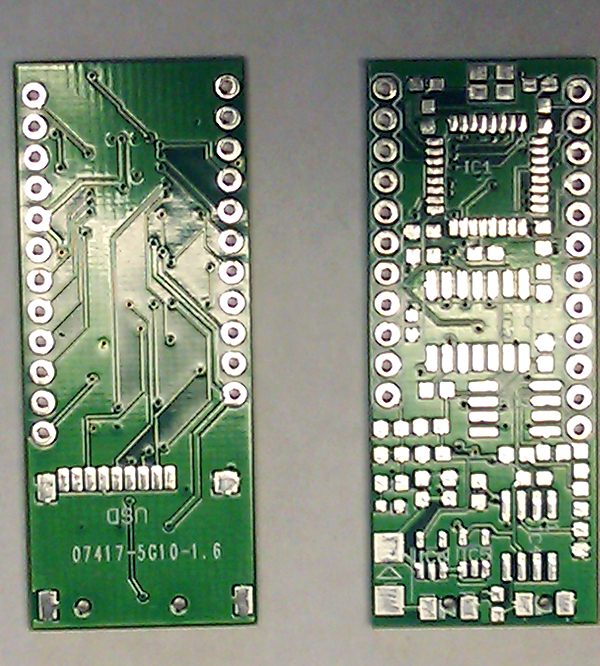

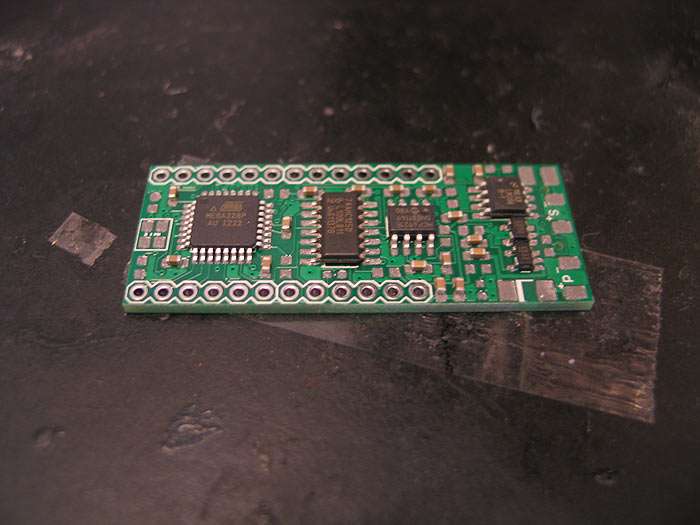

Here was my FIRST generation of pcb's I got made:

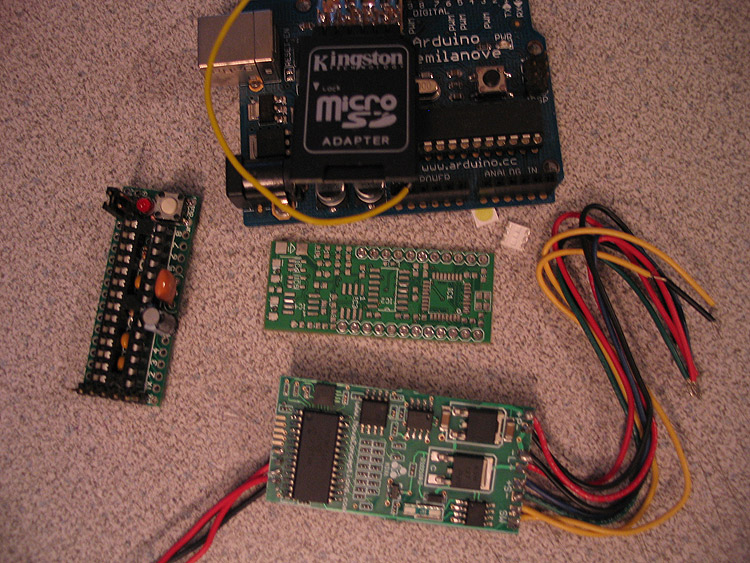

Here is the pcb compared to other stuff.. an Arduino, a smaller minimal Arduino kit..and I think an US 2.5 board:

here I applied my solder paste.. and populated the board with its components..etc. and re-flowed in my wal-mart toaster oven!!

re-flowed:(done)

I had even tried to fix it by testing jumper wires to the default I/O pins..etc.. (no go)..

Well long story short.. after posting and asking....I just couldnt get it working with the DAC I had chosen..maybe someone else could have?? no clue.. (DOH.. should have just followed along..lesson learned)..which I guess is good.. as I had a few other mistakes as well.. =( SO I started over.

In the end, all I had was a tiny Arduino circuit..with on-board uSD socket.. nice.. but no audio output. ![]()

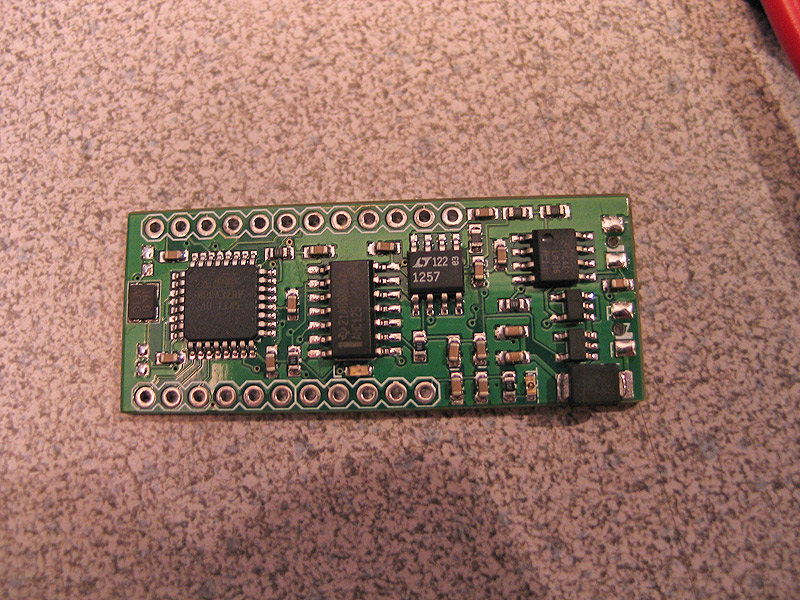

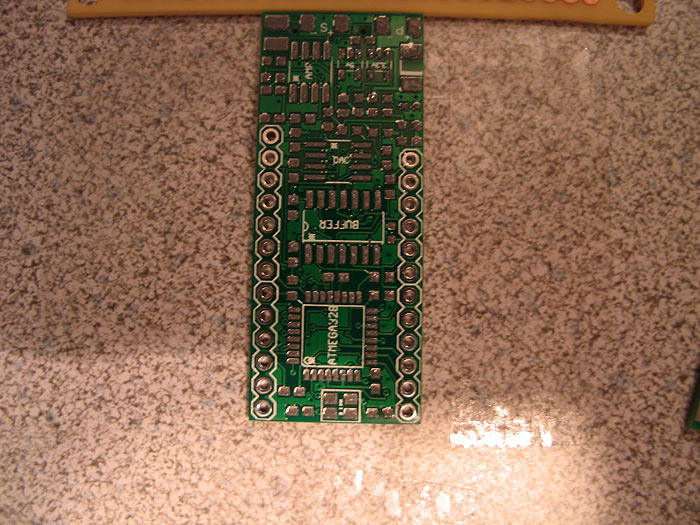

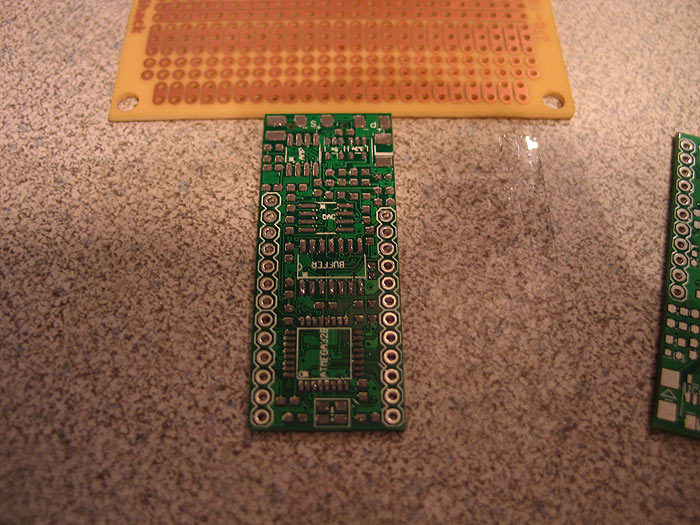

So lets go version 2!!

I got mew pcb's made... got a new stencil made..etc.. and started again.

Here is the process "I" did:

apply the solder paste, using stencil:

remove stencil.. examine paste placement on pads: doesnt need to be PERFECT as the heat from pads will pull solder towards it..etc:

Then populate board: (those TQFP chips are a PITA sometimes!!)

Stick it in the toaster for a bit.. (you can see the solder melt and get shiny)

and when you are done you get a finished board..

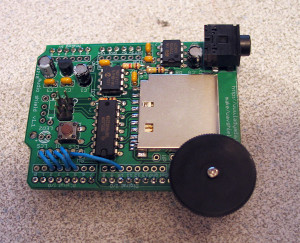

Here are some size shots and comparison shots against a full size Arduino & WaveShield (which is what my custom board is together..those two boards in one)

in the last pic you can see some pots wired inplace of some resistors.. I did this so I could dial in not only the volume.. but play with the filter/range, so things didnt sound so muddy/muted..

when done flash the board with whatever code you wrote to control/do whatever it is you need done.

thanks for looking.. was a fun project..

Arduino: WaveShiled build process

Hey gang-

while I was working on my own custom Arduino based project.. I found myself without a real way to compare the audio output (volume/quality) against the Adafruit WaveShield which I based my project off of)

So I was about to order one.. when I found a guy at my local makerspace that actually had one of these kits. The catch was he had never put it together.

So the barter was on.. I can borrow and test it.. as long as I put it together for him.. (pfft.. no problem!)

Here is my documentation of building an Adafruit WaveShield..

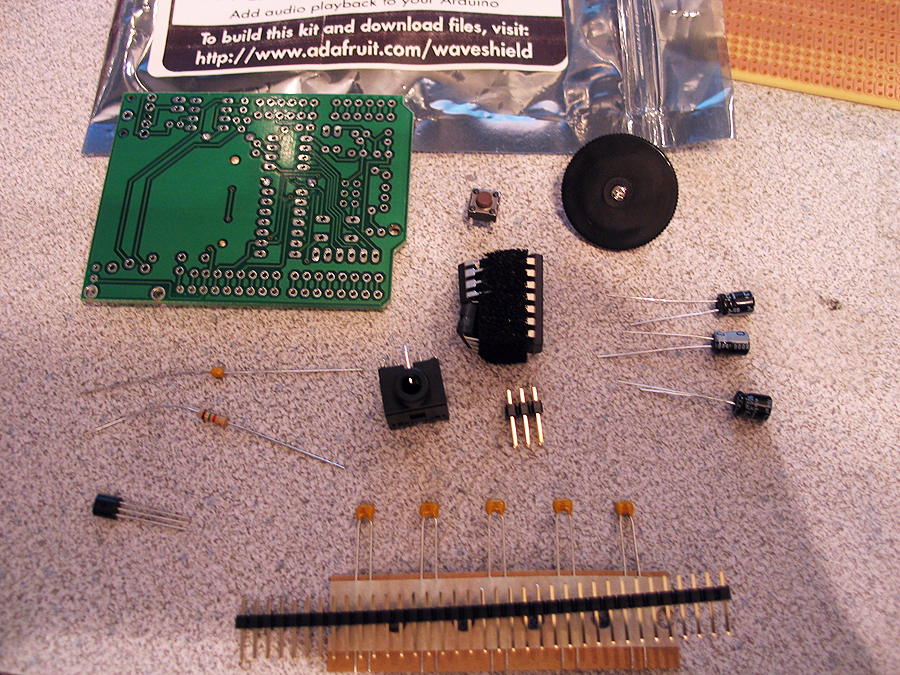

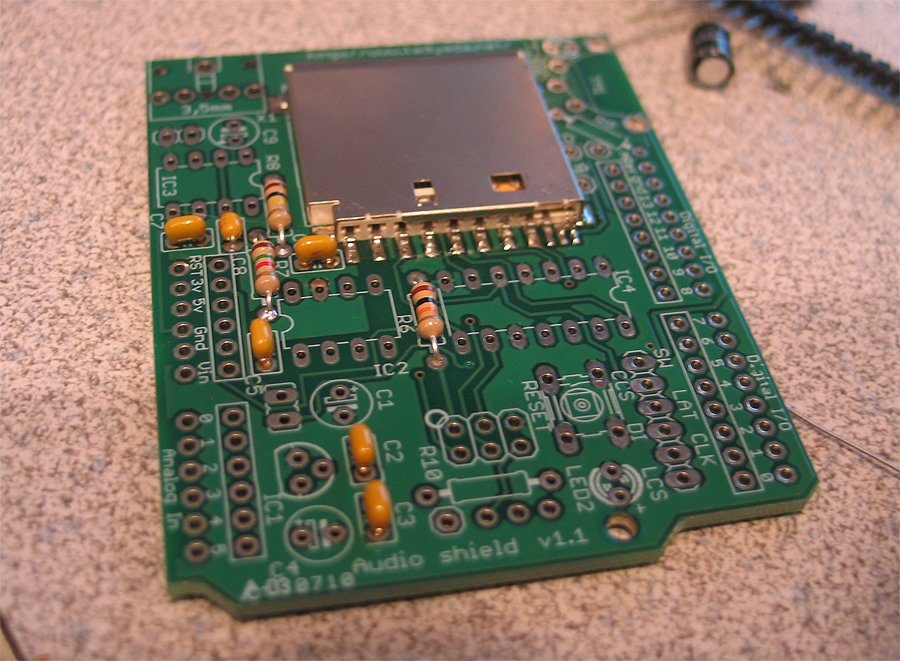

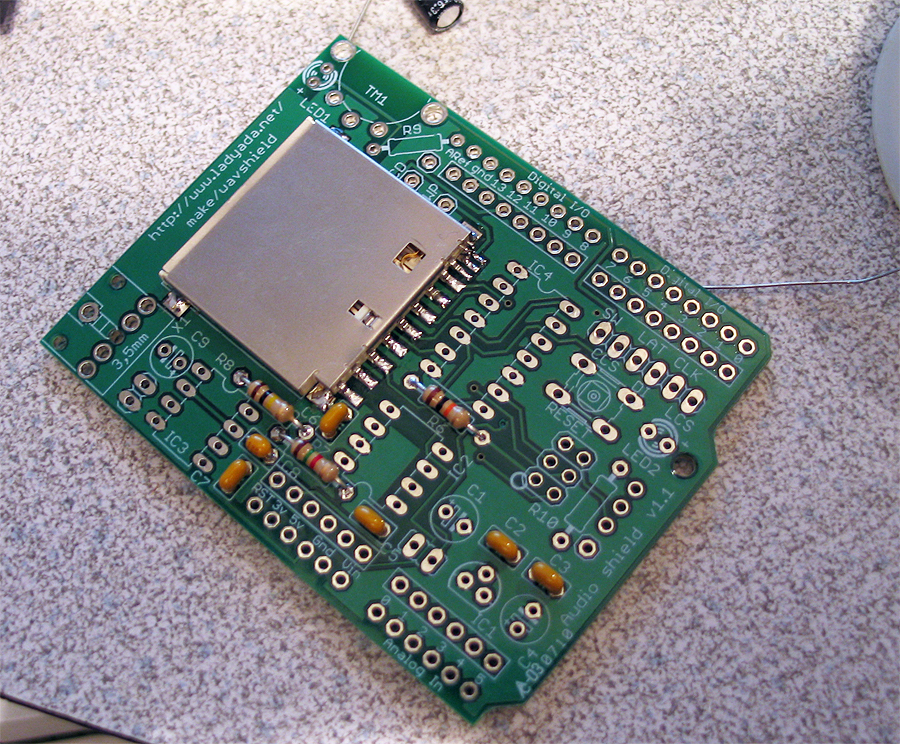

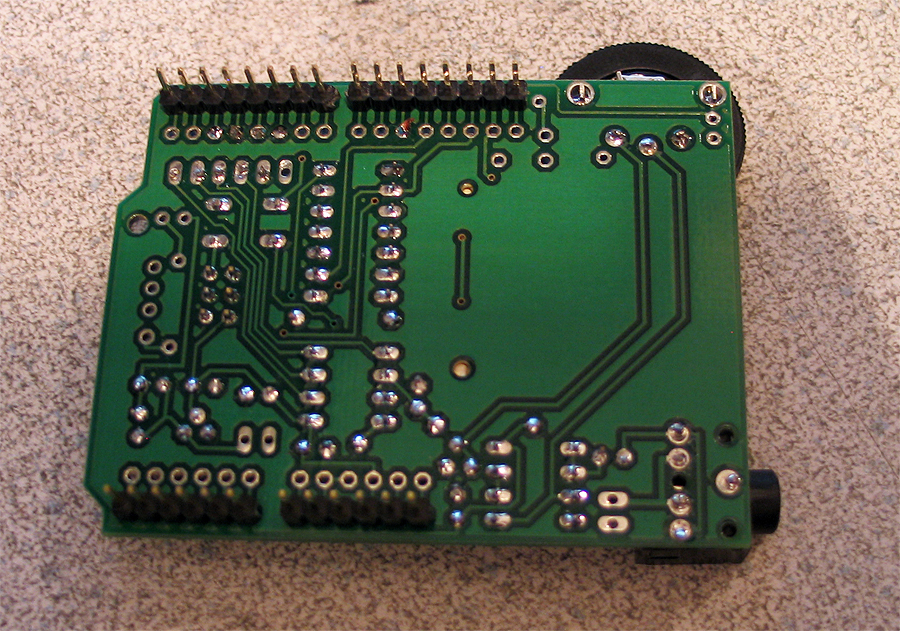

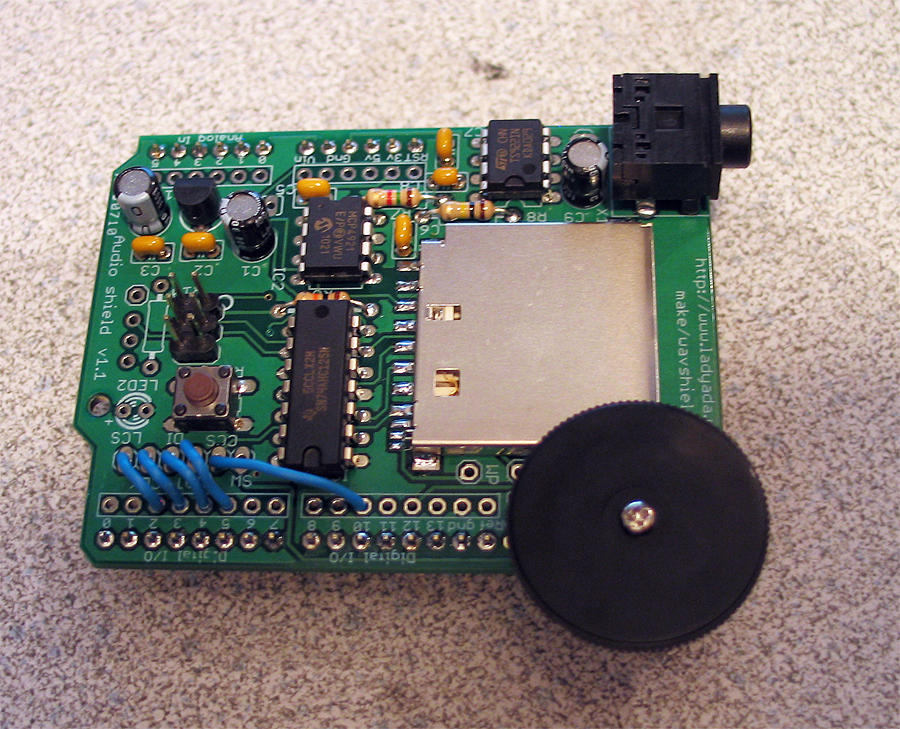

the kit parts:

compare shots against my custom board, for size:

thanks for looking!

summary: nice and easy kit

does what it says in minimal time and effort

volume quality is 'not' that great.. (but they know about it.. and they provide a resistor hack for adjusting the volume)

the filter/range is a bit muffled too..

over-all its better than straight, un-filterd, un-amplified PWM audio! and its only around $20.00

PS.

special thanks to Pete P. @ the local Milwaukee Maker Space! (you guys rock!)

DIY: Homebrew PCB etching

Not sure how many (if any) of you may ever need to do this...

but if you want to mount those sensors we got or accent leds..(or anything) to a little custom PCB for your projects..

you can make a PCB all by yourself with nothing more than a black-n-white laser printer, the copper pcb board, and some etchant solution

Etchant Solution:

http://www.radioshack.com/product/index ... Id=2102868

I think they stopped making them..but some stores still have old inventory.. (I got my last 2 kits for $3+ each)

# 276-1576 is the KIT# (read the description, and you'll see reference to the kit)

comes with:

etchant solution

tray(s)

etchant/ink remover solution

copper PCB board (2 thicknesses)

drill bit

scotch brite pad

permanent ink marker

you really only need the etchant and the copper pcb board.

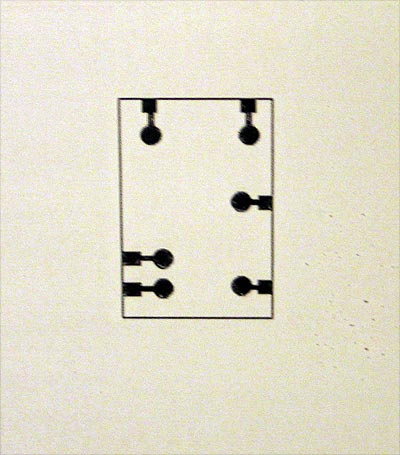

I made a little layout/schematic (nothing special)

in photoshop.. @ 300 DPI

** make sure you print on glossy PHOTOPAPER.. this works best in my tests..

print out your schematic..

cut out schematic

iron schematic to the copper pcb board... let it sit a bit.. make sure transfer is nice.

under cold water.. 'wash away' the photo paper on the PCB board.. it will leave behind the INK/TONER from the paper on the PCB..

(I didnt take a pic of this....sorry)

but it would be like you printed ON the PCB (more or less) after you wash away the photo paper with water.

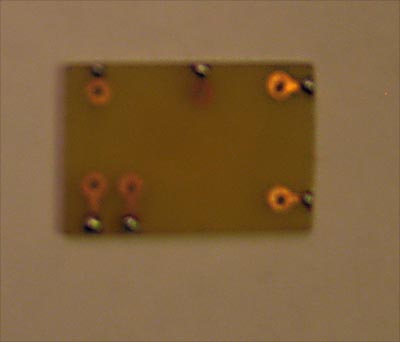

fill tray up with etchant solution..

throw section of pcb board with print out ironed on it..into tray..

(etchant will eat away/remove ALL copper 'except' where the ink/toner was left at)

once all copper is gone..and only black ink/toner is left on board...

you can take high grit sand paper or the scotch brite pad..and clean off the toner that was left on the board.. revealing the copper (now traces) on the board..

It can be used to get some fairly decent lines and things are very crisp for what it is..

I made a 'pcb' board to hold my X & Y axis swing sensors....and my clash sensor.. and soldered solid core wires that fit into my bread board to test with the RFX project..

Ive also used this method to make a few LED driver boards to drive a LUXIII/P4 w/PWM support... as well as a 3 & 4 driver board for RGB or RGBA diode LEDS..

I made these printing on WAX paper though..and the transfer isnt as good after ironing as using glossy photo paper and washing it away under water after ironing.

and these are just HOME BODY, DIY needs..and they work a treat..

image how small things could be if they were professional designed and manufactured!! PHOOK!>.lol

hope this helps any of the DIY builders out there..:)

-----------------------------------------------------------------------------------------

For these tests...

I have used a very affordable HP LaserJet 1022n (n = networked)/

basic stock black-n-white laser printer.

as for photo paper.. I have success with several brands, sizes & type.. glossy or semi-gloss all types were..

all transfer CLEAN, SOLID lines..vs. using a wax paper or a mailing label backing or similar..

I was very impressed with the quality of transfer using photo paper vs. anything else.

re: etchant.. a few other things to note..

myself. (wrong or right).. I keep my solution in a plastic tub/container.. (with lid)..and just leave it.).. I re-use it.. sometimes adding more or etchant at times..

also adding air/bubbles to the solution helps speed up the process and works well...

my point/goal was to provide a method that doesnt require any special ordering of materials or supplies.. everything should be able to be purchased locally...for cheap!

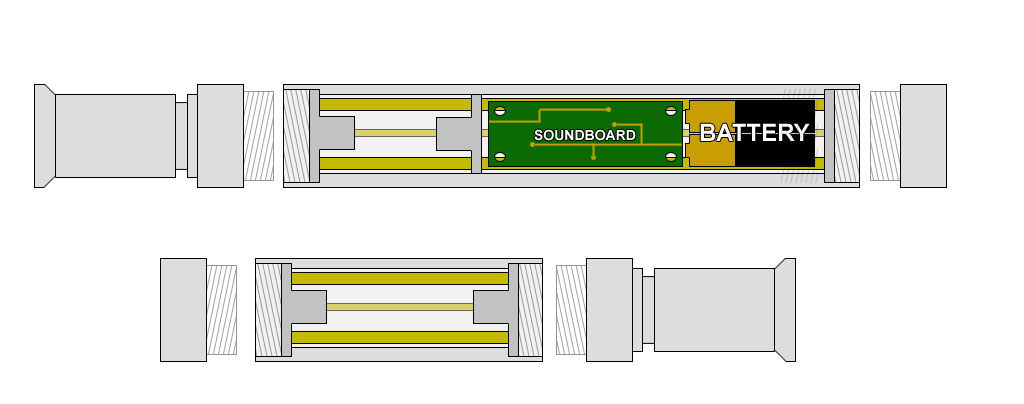

xCore: #1 (HAL)

I dont think I ever posted these (I didnt see them at least in this thread)

I expanded on my 'xCore' (cough cough)..lol..

to make in more like others (Goodman, Big Ez commented on..etc..etc) about making the 'core' a stand alone unit..

I tried to make it generic enough to work as many build as possible.. (chokes etc..probably wont work without custom install & wiring..)

I made a couple like this where the battery pack, crystal chamber, LED & switch housing is all on unit.

I can fit 2AA & a USB board in the battery compartment, behind the speaker....so speaker, battery & US board.. think of TCSS all-in-one sound system with a 'sleeve' over it..

I went for mounting the switch as HIGH as possible tot he LED as I could.. about 1" down from TOP of led heatsink )a lot less from bottom of heatsink)

the 'crystal' stems/holders both were made to hold 3mm chrome bezels from RadioShack.. the backs are count ersunk to hold nut and screw in place to lock.

so each one 'can' have an led in it same color, different colors.. RGB accent leds..etc..

I dont have any crystals yet to play with..

but the led holder stems will be cut down (faced) to make them a little smaller....as well as the brass rods/threaded rods.. to match whatever crystal I end up using.

right now I think its about little over 1" long crystal room..

after final cuts, it will be around 6.5" I'd say..

these were all rough cuts, eyeing things up for the most part.... using junk/crappy jigs..

once I get some measurements, prototype results..I can make some nicer ones sanded and polished..etc..

switch is illuminated switch of course..

you can see light here..

checking out different 'stems' and switch caps/heads... most have hole drilled in shaft to let light through..

most of the sections are 'modular'.. and can be broken off from the 'main' core (if you will).. to work with specific saber designs..

all of these of course take advantage of the MHS 'locking' feature for the speaker and/or the heatsink..

I 'piggy' back off one of those (depending on the saber design and the core design).. and use that part to lock & secure my whole core down.

in these pics.. they are actually in-accurate.. that is a stock width speaker holder I am using..

however (unless I measure perfectly).. because I am using the heatsink to lock my core down..I need to turn down the the OD of the speaker holder...so it can fit inside of the hilt body...

the holder needs to be turned down 'slightly' t be used with the sleeve/bucket.. but the OD needs to be turned down more for it to fit into a MHS hilt..

wiring is tricky..you can only get some many wires up the small 'false tube'.. I think I got 7 or 8 up there..small gauge.

and getting 2AA and a US board in there..take some serious Eastern cram-fu. but it works.

I think I can make that small OD false brass rod a bigger (normal sized) one to allow for more wire room.

anyways.. its pretty clean wire wise. all hidden.

some decorative lathe & mill work on the parts/sleeve and they could be pretty slick looking.

feedback appreciated..

thanks

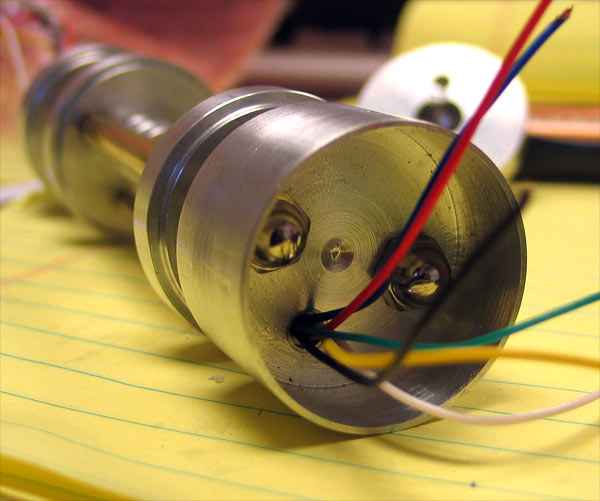

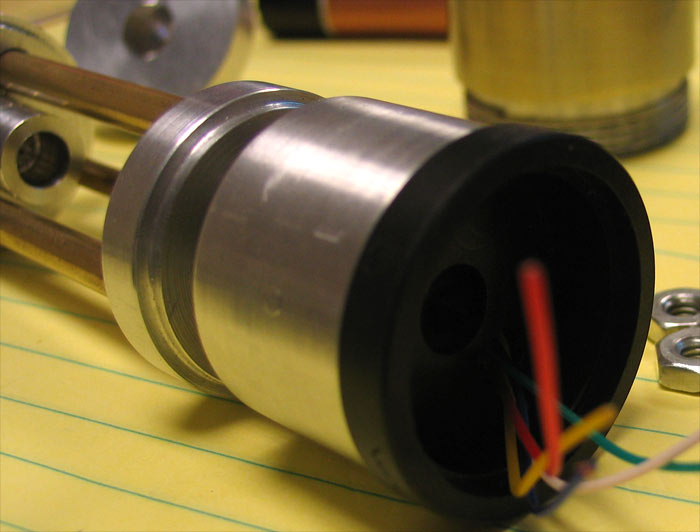

Prototype chassis: #1

So the wife and kids were gone for a few hours today! WOOT!..and I had some time to get in the garage..

I worked on a prototype of a crystal chamber Ive had in mind.. not too much different that all the other versions I have seen..

I basically got the idea from using to inverted heatsink type pieces and others may have done..

the smaller end is bored out to hold the actual crystal.. but I have also drilled and counter sunk the inside to hole a LED w/holder..

same can be done with the top end (to hold an led) to do two different colors..same color..or left empty..

all holes to hold the brass rod is counter sunk so they hold..with threaded rod internally..

the 3rd smaller rod is counter sunk as well....and has no threaded rod.. it will be sandwhiched between the two 'plates'/holders...and be empty so you can run wire through it (like in the pic).

I have been working on several different versions of the 'holders'... which you could mix-n-match I suppose

1.) is a 1.25 OD...so it can fit inside the normal MHS parts.. (its not pictured in the images however)

2.) the one that is pictured..used the same type of approach the heat sink does..smaller that the internal threads ID..but bigger then the inside of the MHS ID.. so it gets caught on the 'lip'...and can be wedged down by screwing a male part.. keeping it tight..

3.) same as #2 but its THICKER..so it can be used in the pommel areas...

(I have been trying to think or or work out a way to secure a speaker to the end nicely..I was thinking just a little extended part to secure things too..and use the hollow rod to run wires through... the flip side of this is..trying to get a version that gives a knock-off LDM crystal pommel... and NOT block the speaker/sound... but that will need some redesign.

what ya guys think?

side/profile pic.. image same thing on top (not pictured)..but with either a disk OD that is 1.25 or 1.31 using to 1.31 sized OD disks..means you could make one that fits nicely and secure in one of the crystal chamber MHS parts.. or just fit inside the ID of an MHS part

bottom: (there is an led and I bored out big enough so you can use tweezers or clips to secure the nut on the led holder)

top/led shot:

no SaberForge jokes.. the grease/grit is still there... LOL it can all be wiped off...and polished up.. none its chatter or scratches....LOL

I didnt have alot of spare brass rod and threaded rod.. od I would have made some more mocks of it with a sound board...batteries.. but you get the idea..use your imagination. ![]()

This might be a god idea for "Tim" to looking into...

with professional craftsmanship... these would be NICE!.. all holes counter sunk to correct depth.... all rods cut to perfect exact length.. (not on a bandsaw by hand and eyed up!) LOL

-------------------------------------------------------------------------------

I was thinking it can be expanded to be something like this.. want more room..add another disk..and any size/length brass/threaed rod..

problems/changes

1.) rods need to be a little closer to the 'center' so if you use nuts to lock in a 'middle' disk (so to speak).. it has room..I think my clearance now is slim to none..LOL

2.) using acorn nuts at the bottoms is a wash..if you plan on locking down/sandwiching the disk with a male part.. however we might be able to just partially 'thread' a hold so you can thread the threaded rod into it..no acorn/flat nut needed on the BASE (of one end at least).. if you wanted to lock 'two' bases by male threads..one might need to be left hand threaded?? if one internal and one a sandwiched one.. acron/flat washers could be used no problems..

thoughts?

-----------------------------------------------------------------------------

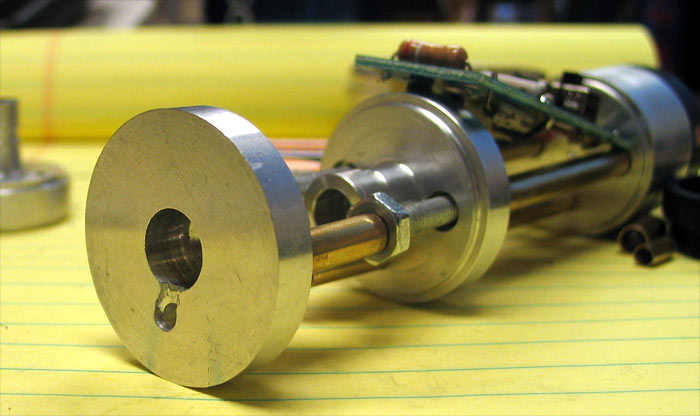

heres an update.. I had a few hours in the garage yesterday..and revised some rough cut pieces.... its pretty versatile.. (IMHO)

as stated above.. I planned to take use of the already built in 'locking/securing/sandwiching' systems that all MHS parts utilize.. an that it by default all threaded parts leave a gap.. and this is for the thickness of either a heatsink.. or a speaker holder (if its a pommel)..

so that is what I based how to secure this 'core/chamber..etc)

these are ALL PROTOTYPES.. ROUGHT CUTS.. no fine cuts.. no filing,sanding/polishing..etc.. and only 1 jig used.. that was eyed up.. ![]()

all disks/sections.. come in 2 thicknesses..

1.) regular heatsink thinkness

2.) speaker holder thickness

all disks/option are either:

1.) heatsink OD

2.) 1.25 ID (to inside of MHS parts)

3.) smallest size that fits in the RIBBED sections

What size disk you use depends on your set-up and where, how you want to mount/use it.

this set-up is using the SPEAKER holder as the MOUNTING area.. where as the pommel secures locks down the speaker holder..(and hence the 'core section' is secure to that with a center drilled/tapped middle (not pictured)

So its (going up)

speaker bucket / crystal chamber / extra space for sound board and/or battery pack..

same pic on its side:

same as the ABOVE pictures in the previous post.. the 'stems' are drilled out and counter sunk to hold the LED and holders in place.. and secure with another counter sunk hole for the nut.

Also all brass rod holes are counter sunk.

[img width=589 height=768]http://dmstudios.net/misc/prototype-1a/core_prototype-1b/ledHolder.jpg">

I made a little speaker bucket.. that holds a slightly turned down speaker holder.. (only the portion behind the lip was turned down)

(I put a little space between the speaker bucket and the bottom of the crystal stem..sing tiny brass rod sections.. gives a little gap to run a wire to the led in the bottom holder

it is deep enough to have room for the acorn nuts..and hide wires..or even snake more through for a bottom re-charge port..

speaker holder is stock OD at widest point..so I can slide it in a a threaded opening on most MHS parts.. and lock it down with either a pommel

I even made another speaker holder that has OD of 1.25 so the whole speaker/holder & bucket can sit flush inside (ID) of a regular MHS part..

if you go this route... you obviously will not be using the speaker holder/pommel to lock/secure the core...

so you would need to use a disk/section that can be locked down by a choke or blade holder..erc

I made some with and without the crystal stem/holder end..

so its really however you want to design it... crystal chamber & speaker.. or add another section to hold a sound board..or battery pack (just another disk and some brass rod w/threaded rod) cut to whatever length you need/want

you could use this secure/trap a crystal chamber in a ribbed section that has a section cut out..

just use a disk that can be secured by another male threaded part...and a disk that has the OD of the ribbed section ID..to keep things nice and tight..

as a final part to this.. Im working on a variation that uses (is) the heatsink for the LED..

this would make this all one unit/core/chamber piece... ![]()

here us JUST a speaker and chamber combo:

[img width=258 height=768]http://dmstudios.net/misc/prototype-1a/core_prototype-1b/speaker-chamber.jpg">

There is a 'falsey' brass tube that is hollow just to run wires cleanly..

another pic of the base that secures/locks down like heatsink

free floating speaker to give more res. chamber for sound..

all bases with stems can have an LED... 1 color, 2 colors, RGB LED in there..

all bases withOUT stems are half threaded holes.. no through holes..except for the falsey brass/wire hole..

thoughts/ discuss? love/hate? ideas? suggestions?

Thanks

----------------------------------------------------------------------------