xCore: #1 (HAL)

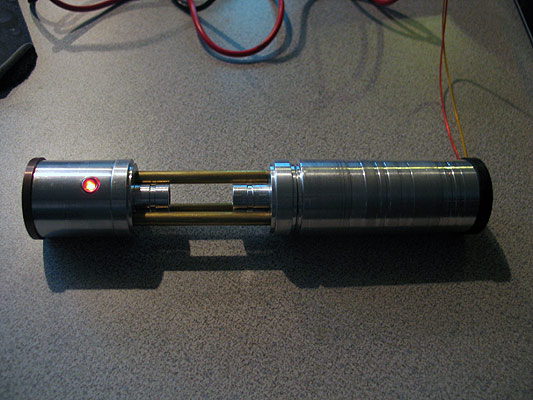

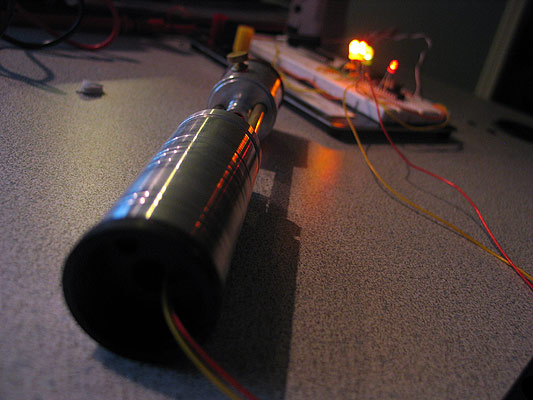

I dont think I ever posted these (I didnt see them at least in this thread)

I expanded on my 'xCore' (cough cough)..lol..

to make in more like others (Goodman, Big Ez commented on..etc..etc) about making the 'core' a stand alone unit..

I tried to make it generic enough to work as many build as possible.. (chokes etc..probably wont work without custom install & wiring..)

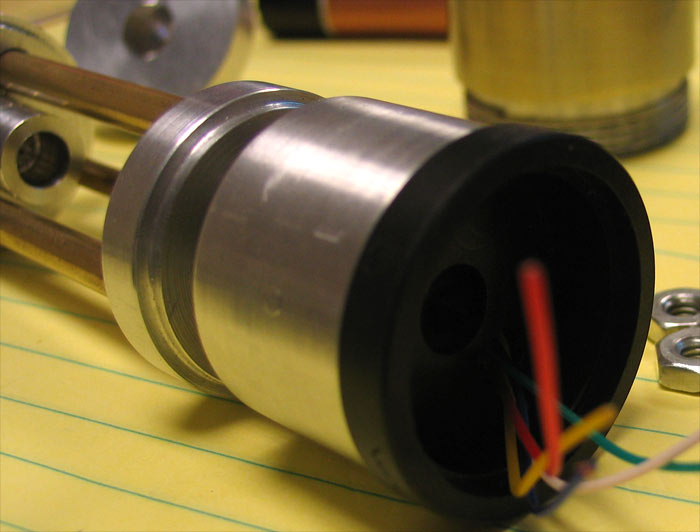

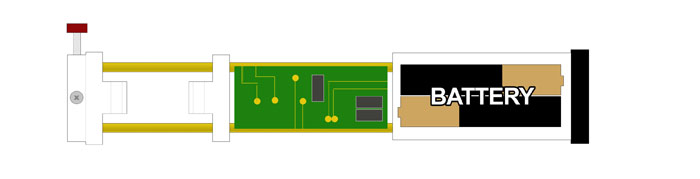

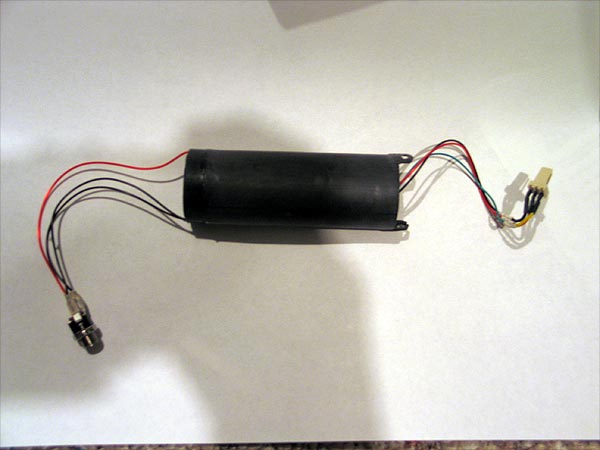

I made a couple like this where the battery pack, crystal chamber, LED & switch housing is all on unit.

I can fit 2AA & a USB board in the battery compartment, behind the speaker....so speaker, battery & US board.. think of TCSS all-in-one sound system with a 'sleeve' over it..

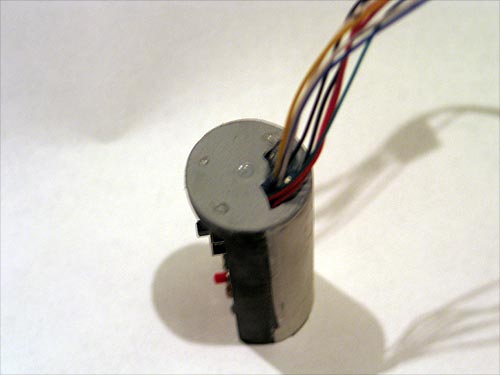

I went for mounting the switch as HIGH as possible tot he LED as I could.. about 1" down from TOP of led heatsink )a lot less from bottom of heatsink)

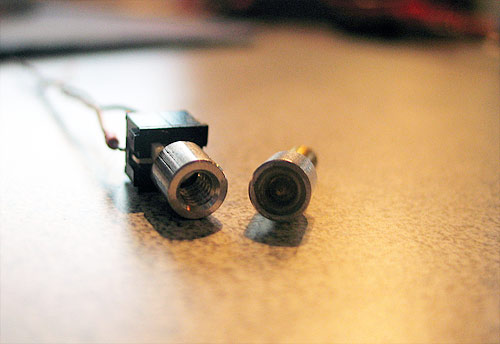

the 'crystal' stems/holders both were made to hold 3mm chrome bezels from RadioShack.. the backs are count ersunk to hold nut and screw in place to lock.

so each one 'can' have an led in it same color, different colors.. RGB accent leds..etc..

I dont have any crystals yet to play with..

but the led holder stems will be cut down (faced) to make them a little smaller....as well as the brass rods/threaded rods.. to match whatever crystal I end up using.

right now I think its about little over 1" long crystal room..

after final cuts, it will be around 6.5" I'd say..

these were all rough cuts, eyeing things up for the most part.... using junk/crappy jigs..

once I get some measurements, prototype results..I can make some nicer ones sanded and polished..etc..

switch is illuminated switch of course..

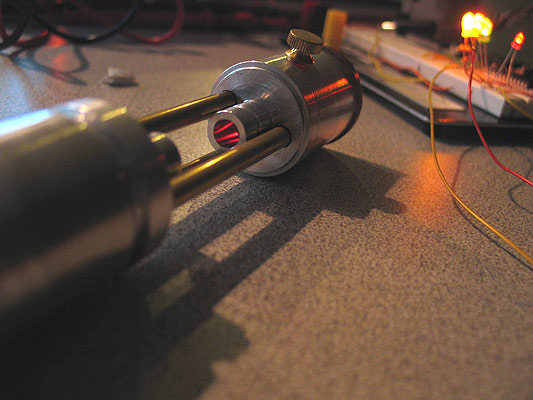

you can see light here..

checking out different 'stems' and switch caps/heads... most have hole drilled in shaft to let light through..

most of the sections are 'modular'.. and can be broken off from the 'main' core (if you will).. to work with specific saber designs..

all of these of course take advantage of the MHS 'locking' feature for the speaker and/or the heatsink..

I 'piggy' back off one of those (depending on the saber design and the core design).. and use that part to lock & secure my whole core down.

in these pics.. they are actually in-accurate.. that is a stock width speaker holder I am using..

however (unless I measure perfectly).. because I am using the heatsink to lock my core down..I need to turn down the the OD of the speaker holder...so it can fit inside of the hilt body...

the holder needs to be turned down 'slightly' t be used with the sleeve/bucket.. but the OD needs to be turned down more for it to fit into a MHS hilt..

wiring is tricky..you can only get some many wires up the small 'false tube'.. I think I got 7 or 8 up there..small gauge.

and getting 2AA and a US board in there..take some serious Eastern cram-fu. but it works.

I think I can make that small OD false brass rod a bigger (normal sized) one to allow for more wire room.

anyways.. its pretty clean wire wise. all hidden.

some decorative lathe & mill work on the parts/sleeve and they could be pretty slick looking.

feedback appreciated..

thanks

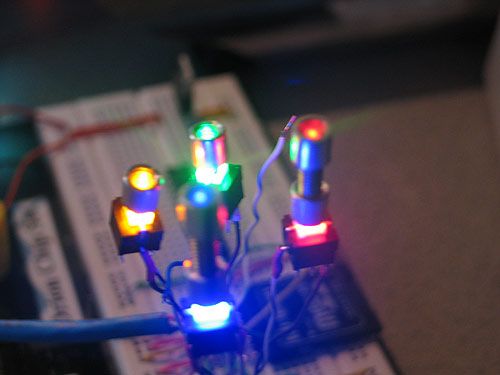

Prototype chassis: #1

So the wife and kids were gone for a few hours today! WOOT!..and I had some time to get in the garage..

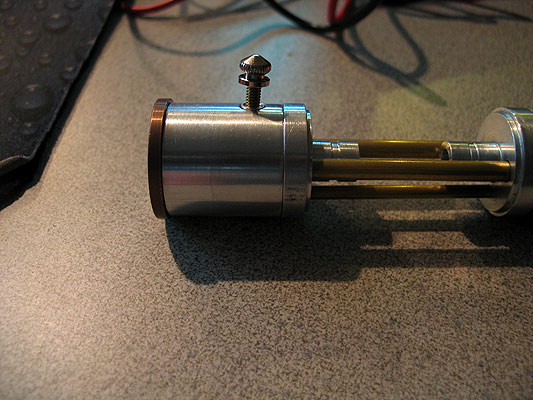

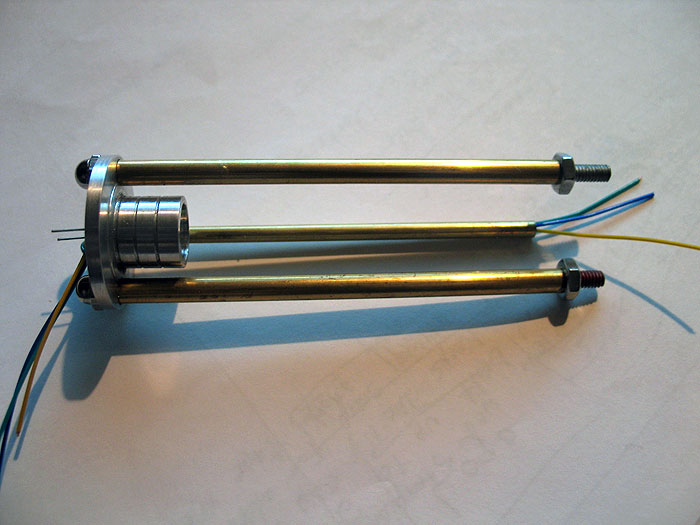

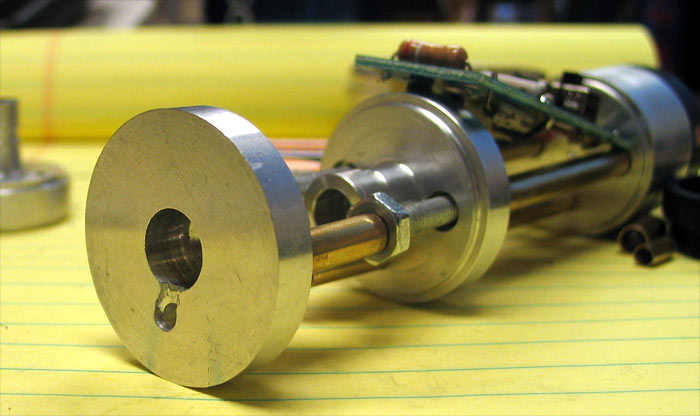

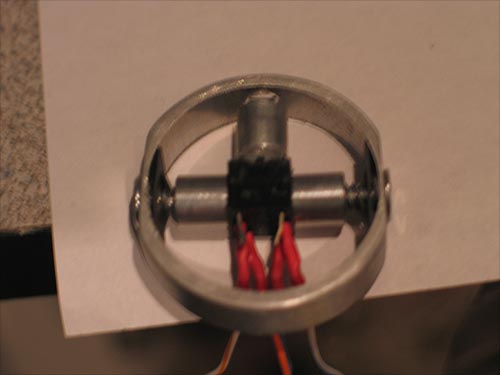

I worked on a prototype of a crystal chamber Ive had in mind.. not too much different that all the other versions I have seen..

I basically got the idea from using to inverted heatsink type pieces and others may have done..

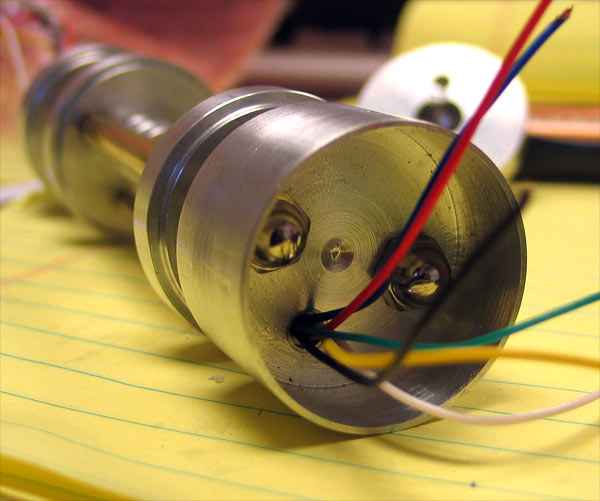

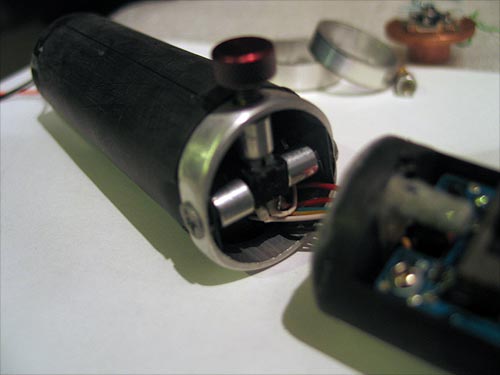

the smaller end is bored out to hold the actual crystal.. but I have also drilled and counter sunk the inside to hole a LED w/holder..

same can be done with the top end (to hold an led) to do two different colors..same color..or left empty..

all holes to hold the brass rod is counter sunk so they hold..with threaded rod internally..

the 3rd smaller rod is counter sunk as well....and has no threaded rod.. it will be sandwhiched between the two 'plates'/holders...and be empty so you can run wire through it (like in the pic).

I have been working on several different versions of the 'holders'... which you could mix-n-match I suppose

1.) is a 1.25 OD...so it can fit inside the normal MHS parts.. (its not pictured in the images however)

2.) the one that is pictured..used the same type of approach the heat sink does..smaller that the internal threads ID..but bigger then the inside of the MHS ID.. so it gets caught on the 'lip'...and can be wedged down by screwing a male part.. keeping it tight..

3.) same as #2 but its THICKER..so it can be used in the pommel areas...

(I have been trying to think or or work out a way to secure a speaker to the end nicely..I was thinking just a little extended part to secure things too..and use the hollow rod to run wires through... the flip side of this is..trying to get a version that gives a knock-off LDM crystal pommel... and NOT block the speaker/sound... but that will need some redesign.

what ya guys think?

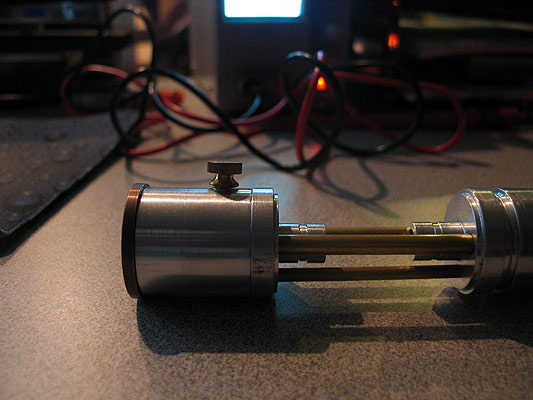

side/profile pic.. image same thing on top (not pictured)..but with either a disk OD that is 1.25 or 1.31 using to 1.31 sized OD disks..means you could make one that fits nicely and secure in one of the crystal chamber MHS parts.. or just fit inside the ID of an MHS part

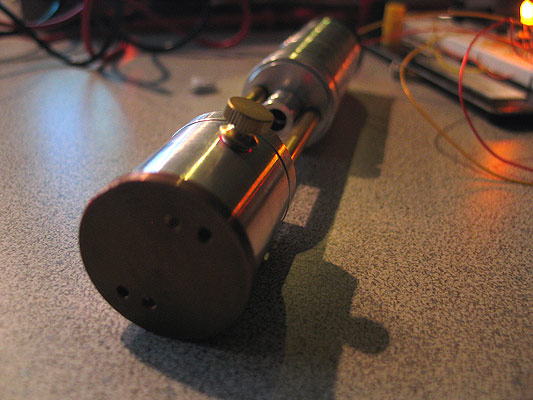

bottom: (there is an led and I bored out big enough so you can use tweezers or clips to secure the nut on the led holder)

top/led shot:

no SaberForge jokes.. the grease/grit is still there... LOL it can all be wiped off...and polished up.. none its chatter or scratches....LOL

I didnt have alot of spare brass rod and threaded rod.. od I would have made some more mocks of it with a sound board...batteries.. but you get the idea..use your imagination. ![]()

This might be a god idea for "Tim" to looking into...

with professional craftsmanship... these would be NICE!.. all holes counter sunk to correct depth.... all rods cut to perfect exact length.. (not on a bandsaw by hand and eyed up!) LOL

-------------------------------------------------------------------------------

I was thinking it can be expanded to be something like this.. want more room..add another disk..and any size/length brass/threaed rod..

problems/changes

1.) rods need to be a little closer to the 'center' so if you use nuts to lock in a 'middle' disk (so to speak).. it has room..I think my clearance now is slim to none..LOL

2.) using acorn nuts at the bottoms is a wash..if you plan on locking down/sandwiching the disk with a male part.. however we might be able to just partially 'thread' a hold so you can thread the threaded rod into it..no acorn/flat nut needed on the BASE (of one end at least).. if you wanted to lock 'two' bases by male threads..one might need to be left hand threaded?? if one internal and one a sandwiched one.. acron/flat washers could be used no problems..

thoughts?

-----------------------------------------------------------------------------

heres an update.. I had a few hours in the garage yesterday..and revised some rough cut pieces.... its pretty versatile.. (IMHO)

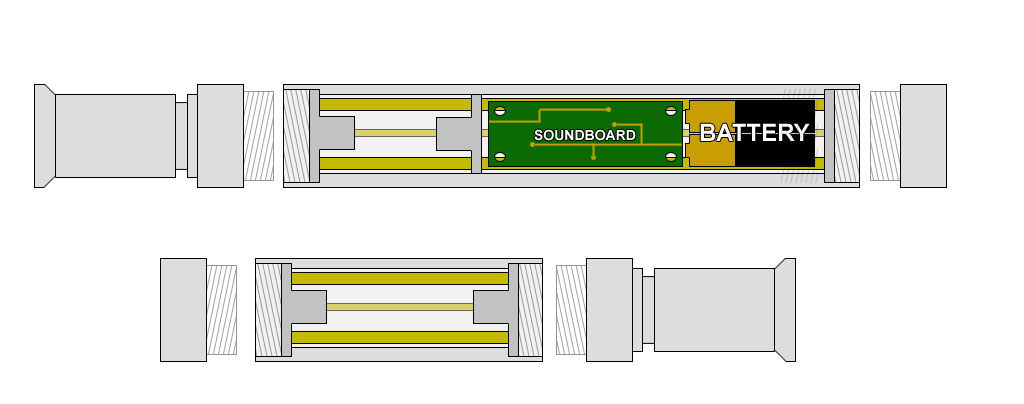

as stated above.. I planned to take use of the already built in 'locking/securing/sandwiching' systems that all MHS parts utilize.. an that it by default all threaded parts leave a gap.. and this is for the thickness of either a heatsink.. or a speaker holder (if its a pommel)..

so that is what I based how to secure this 'core/chamber..etc)

these are ALL PROTOTYPES.. ROUGHT CUTS.. no fine cuts.. no filing,sanding/polishing..etc.. and only 1 jig used.. that was eyed up.. ![]()

all disks/sections.. come in 2 thicknesses..

1.) regular heatsink thinkness

2.) speaker holder thickness

all disks/option are either:

1.) heatsink OD

2.) 1.25 ID (to inside of MHS parts)

3.) smallest size that fits in the RIBBED sections

What size disk you use depends on your set-up and where, how you want to mount/use it.

this set-up is using the SPEAKER holder as the MOUNTING area.. where as the pommel secures locks down the speaker holder..(and hence the 'core section' is secure to that with a center drilled/tapped middle (not pictured)

So its (going up)

speaker bucket / crystal chamber / extra space for sound board and/or battery pack..

same pic on its side:

same as the ABOVE pictures in the previous post.. the 'stems' are drilled out and counter sunk to hold the LED and holders in place.. and secure with another counter sunk hole for the nut.

Also all brass rod holes are counter sunk.

[img width=589 height=768]http://dmstudios.net/misc/prototype-1a/core_prototype-1b/ledHolder.jpg">

I made a little speaker bucket.. that holds a slightly turned down speaker holder.. (only the portion behind the lip was turned down)

(I put a little space between the speaker bucket and the bottom of the crystal stem..sing tiny brass rod sections.. gives a little gap to run a wire to the led in the bottom holder

it is deep enough to have room for the acorn nuts..and hide wires..or even snake more through for a bottom re-charge port..

speaker holder is stock OD at widest point..so I can slide it in a a threaded opening on most MHS parts.. and lock it down with either a pommel

I even made another speaker holder that has OD of 1.25 so the whole speaker/holder & bucket can sit flush inside (ID) of a regular MHS part..

if you go this route... you obviously will not be using the speaker holder/pommel to lock/secure the core...

so you would need to use a disk/section that can be locked down by a choke or blade holder..erc

I made some with and without the crystal stem/holder end..

so its really however you want to design it... crystal chamber & speaker.. or add another section to hold a sound board..or battery pack (just another disk and some brass rod w/threaded rod) cut to whatever length you need/want

you could use this secure/trap a crystal chamber in a ribbed section that has a section cut out..

just use a disk that can be secured by another male threaded part...and a disk that has the OD of the ribbed section ID..to keep things nice and tight..

as a final part to this.. Im working on a variation that uses (is) the heatsink for the LED..

this would make this all one unit/core/chamber piece... ![]()

here us JUST a speaker and chamber combo:

[img width=258 height=768]http://dmstudios.net/misc/prototype-1a/core_prototype-1b/speaker-chamber.jpg">

There is a 'falsey' brass tube that is hollow just to run wires cleanly..

another pic of the base that secures/locks down like heatsink

free floating speaker to give more res. chamber for sound..

all bases with stems can have an LED... 1 color, 2 colors, RGB LED in there..

all bases withOUT stems are half threaded holes.. no through holes..except for the falsey brass/wire hole..

thoughts/ discuss? love/hate? ideas? suggestions?

Thanks

----------------------------------------------------------------------------

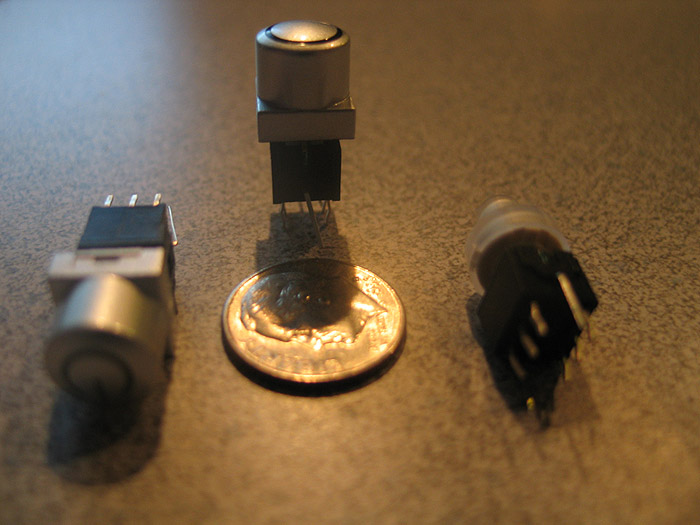

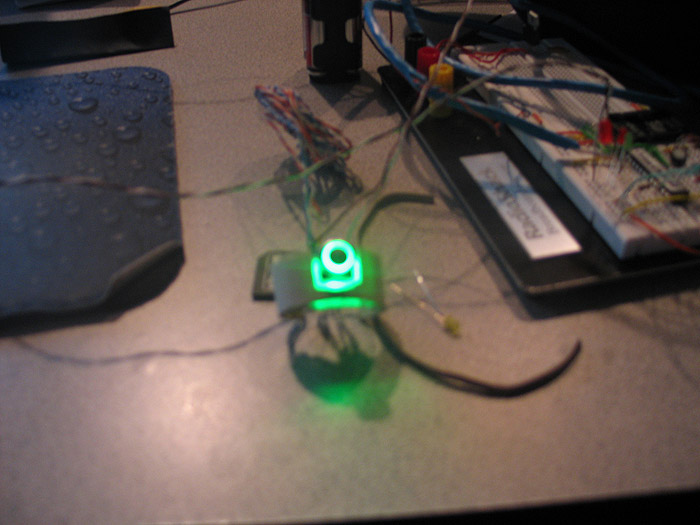

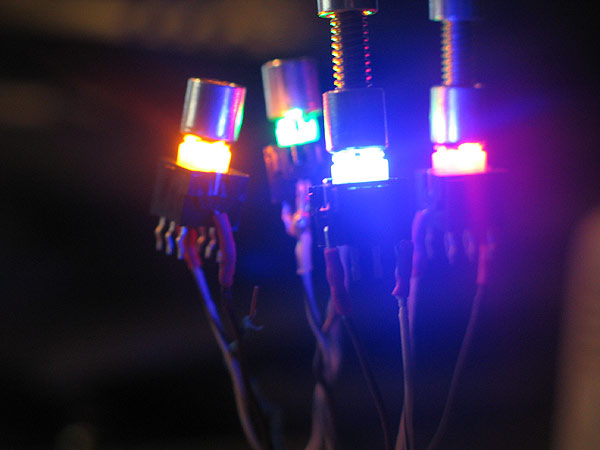

Illuminated Switches: (tiny)

OK.. I talked to the vendor off & on a few times.. and basically for a higher price (and if they are in stock).. he will mix-n-match some switches (led colors) and caps for me:

to re-cap:

pics of the sample switches they sent me..

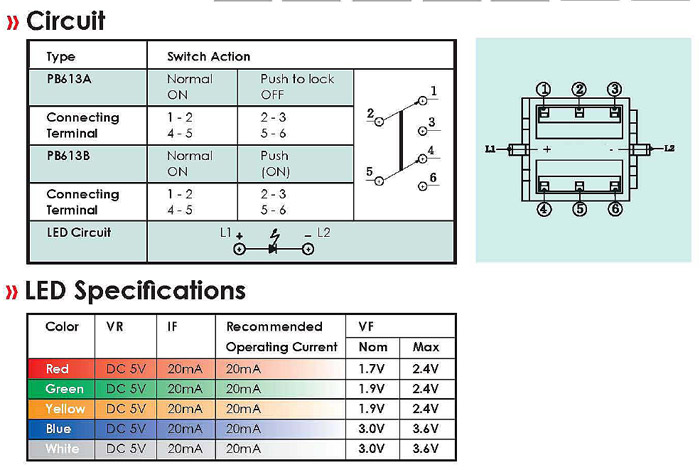

according to the spec sheet:

http://www.rjselectronics.com/PDF/PB613x.pdf

page 2 of 5

it says Switch Action/terminals

Normal ON:

1-2

4-5

Push to Lock/Off

2-3

5-6

the pics are little 'distorted' because of either my shaky hands.. or taking a pic of the LED lit up..

1.) I took all the silver paint off the cap..so the whole thing lights up.. (pretty sick).. tip: to NOT leave the soft plastic/rubber base in while doing it

2.) the second is the default cap with the ring in it.

using the same mounted base.. Im not sure what other colors I got in the 'samples'..

RING:

SOLID:

what we have available to us is:

COLORS:

RED

GREEN

YELLOW

BLUE

CAPS:

BLACK

SILVER

I only asked about getting the RING style (as pictured) but in black and silver (silver is pictured)

If there is enough interest.. I will try to scrounge up the rest of the loot to get an order..

Im thinking they will go for about $5 each shipped..

let me know.

Thanks

------------------------------------ [part II]--------------------------------------------

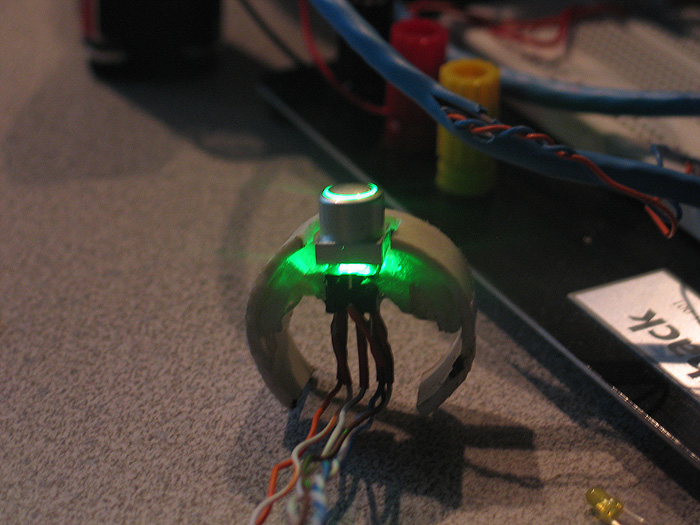

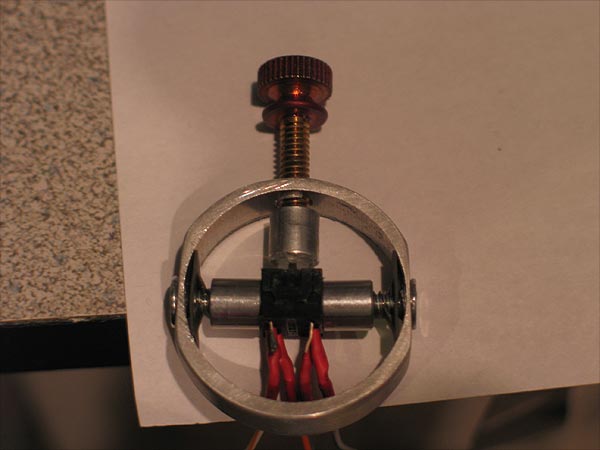

I had made comment about it previously..and am just now getting around to posting the pics I took of these..

My first attempt at using (mounting) these was much along an early Jay-Gon approach using a PVC 'ring' or semi-ring that could 'flex'.. but that solution left things very close to being a 'one way' switch install without potential damage...

so I began to think about alternate ways to mount these (or other difficult mounting switches)..

when I saw Erv's post about modifying the CAPS.. it reminded me to post what i came up with.

Ervs way of modifying the caps is awesome.. (I'll be doing a few like that for sure).. but not everyone has access to a lathe like we do....

it also leaves you stuck with the having a cap style of choice with the bottom ready to 'snap' to the switches stem..

my approach sorta gives you more room to be able to utilize different (metal, ala Madcow) style switch caps for example.

my first prototype was made from not wanting to waste such a small DPDT latching type switch..(just because I had blown the LEDS in 2-3 of them..)..ssshhhh

Something that could fit and be easily mounted inside (1.25 ID) a hilt of a normal MHS section..

and also allow for easy cap fitting from the outside.. (like Erv showed on modifying the cap OD)

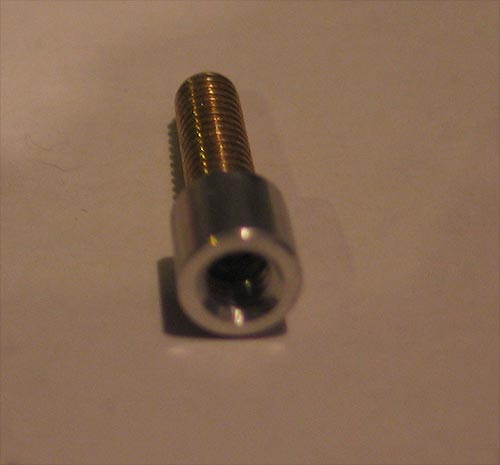

I also took it one step further...and drilled out the stem on one of the thumbscrews so I can mount any type of head I want on it.. (even one with epoxy in it, similar to the screws that let light show through)

its basically a section/ring of 1.25 OD aluminum tubing...with some screws and speed nuts..etc.. with some thread aluminum spaces.. everything can be purchased at Ace Hardware or the like..for a couple bucks..tops.

might throw a dab of hot glue over it just to make sure it doesnt loosen up..but its been very stable so far..thrown all over the place..for weeks now..

I'll get the rest of the pics up, of the threaded stem being illuminated..

(I just need to put he dab of epoxy or something in the tube to diffuse the light more..)

the last pic is where the dab of epoxy will go..

Im hoping it will look like an illuminated, metal 'Madcom' style switch.

the cool thing is..with this 'ring' type set-up.... (much like my approach to chassis' and crystal chambers...etc) it utilizes the pre-built MHS 'feature' of the space in the threads... and to lock down the ring..

this one in the picture fits (tightly) in a 2" section.. in the space left over by the HEATSINK drop down...and having one of my chassis 'disks' locked in by male threads on the other end..

so whats that? a little over 1/4 inch or so?

not 'precision' made, (Im sure others could made a better looking one)...but its not too bad..and you dont need anything fancy... drill/drill press and maybe a sander to grind the sides flat.

feedback? thoughts? improvements?

I'll get some of the illuminated ones posted...

anyone have a suggestion on what to fill the top with first? (epoxy/hot glue)?

---------------------------------------------------------------------------------------------------------

Yeah..looks a little more 'technical'.. and isnt an eye sore in a build..

I have even integrated this 'ring' section into one of my chassis disks (so its all one piece of aluminum)..

so the chassis disk 'portion' gets sandwiched between the male threads and the internal threading 'lip'..and this switch mounting 'section' is after that (still all one piece of aluminum..just turned down a bit for the OD to fit the ID.). ![]()

this diagram might help..

Heavy dueling? I guess I couldnt say.. "I"personally dont duel..

but they are fairly sturdy.. I mean Ive thrown what you seen in the picks around..at walls.. dropped it.. nothing ever moved or popped out of place..

but as I said.. I'll probably just throw a dab of hot glue in the corners to secure it more so nothing gets un-threaded or anything..

but how much 'pressure' you think it'll have on it? and from where? (what point?)

depending on how you implement this type of approach in your project..

(unless the rest of your 'guts' are free floating and sliding all around).. Id say this 'option' whether it be part of another 'disk/section' locked down, or its own ring not secured by anything expect the 'threaded post' of the switch will function & hold up well.

thanks for the looks and comments.. hope someone finds it useful..

---------------------------------------------------------------------------------------------------------

I dont think I ever really posted these images (in public at least) haha..

these are sorta old.. (about the time when I first found these switches and got some samples..and was left with mounting quandaries) ..at the time I was altering a JGJ approach I had seen in some build thread or something..

BEFORE I started working on the 'modular chassis disk' business.....(which is a much nicer looking and more versatile system) haha ![]()

I used what I had available and much of it was hardware stuff..pvc/plastic.

I still find these regular golf club protectors/tubes to be GREAT for chassis building.... and I have used them a few times in the past for stuff..

I have my 4.8v Nihm battery pack (the one that TCSS used to sell a while back).. and a speaker mount..

the project this was for has a pommel mount recharge port:

filed 'channels' into the speaker mount so I could run wires past it to the pommel for the RCP..

other end had a 3 wire connector (GND, V++ and speaker) to connect to other sections..

(these innards are very modular themselves)..

battery/speaker section

switch section

sound/driver board section

**legs/ladders on the ends with holes in them..as that is where the switch ring mounts/connects to that piece (very rigid)

soundboard/driver board:

using part of PCV and old 616 mount..

I have, the 616, Plecter dimmer, 2 clash sensors.. (before we did bulk order..thanks AK)..

I think I studied with Eastern to get some cram-fu lessons in this thing (**bonus pic at end)

use the top/lid of film canister to make a 'cap' so to speak so nothiner metal would short out on the switch mount ring/chassis

all 3 section together get me this:

all of it fit inside MHS ID.. the the speaker sanded to press fit and it 'tight' and secure..

its nice little core... nothing fancy since its plastic and a little hot glue in places..

here is a pic of the ring mounted in the battery/speaker section..

wires are tight & clean... (I could have probably shortend some of these in hind site to make fit easier).. every is of course heatshrinked and everything is in male/female connectors..

switch has connector (so it can be serviced)

speaker/battery section has connector

led is of course quick connect as well...

for bonus points..

I solders a clash sensor to plecter dimmer for the flicker effect on clash (needs fairly fresh batteries to see it well)

I also soldered a momentary switch to the plecter dimmer board so you can access the menu and change the flicker effect, ramp up/down times..etc..

and mounted it in the 616 board.. looks nice..

no wires seen on top.. so if you want to switch the sound font to be jedi or sith..you can also use the momentary button to access/set the dimmer options as well

these switches.. are 'very cool' IMHO.. and being illuminated shows even more possibles.. (watch for 'custom' illuminated switch heads post soon)

I think these way of mounting is VERY practical..

why?

it can be done by any/everyone with or without a lathe.. 1.25 OD tube.. a tube cutter.. a drill/drill press.. and a sander

it can be incorporated into other 'sections' of a chassis fairly easy..

when you see the version that is incorporated into the modular chassis disk it makes it 'all' look so nice and professional.. instead of a nice chassis.. (made out of whatever).. and then some button/switch hot glued or wires running long was down the chassis..

anyways..hope you all like..and it helps others mount these switches (or anything for that matter.. tiny recharge port of Easterns for example..) (hint hint)

--------------------------------------------------------------------------------------------------------------------

wrap this thread up..

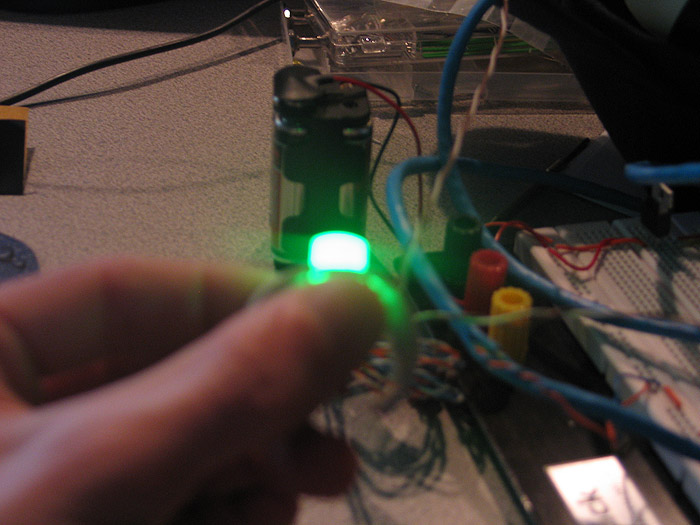

here are some of the pics of the switches and the colors of the LEDs (while on)..

you can see the style of caps Ive been using/making to:

1.) deal with easier mounting

2.) still utilize the illuminated/led option of the switches.

these have hot glue in the caps to diffuse the light.. (its too 'clear', something more 'foggy' is needed to diffuse better)

(I also think the small 'hole' in the threaded stem limits maximum illumination as well..)

I have another pic (cant find where I saved it!?) haha.. showing how 'low profile' you can get with alternate cap/heads (like a metal thumb screw)

I think either turn down the stock caps OD/base on a lathe..or making a custom stem/cap combo is he best way to go for these...

with the aluminum 'heads/caps' picture above.. you can actually almost 'flush mount' them depending on the 'ring width' on where internally it is mounted in your part.

later...

------------------------------------------------------------------------------------

update: thanks to tip provided by 'erv', these switches can be both (default) latching.. and after a mod can also be a momentary switch! great tip! and makes these even MORE useful.

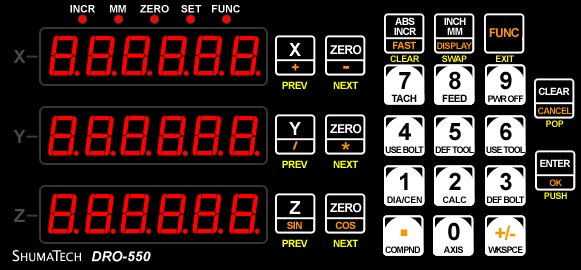

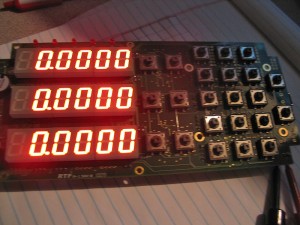

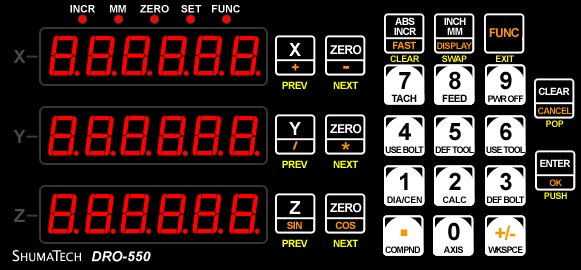

Shumatech DRO-550 Build-Log

Shumatech DRO 500 DIY:

Link: http://www.shumatech.com/web/products/dro-550/power-buy

http://shumatech.com

SHUMATECH DRO-550 PROJECT: [PARTS LIST]

$75.00 (may go down... this is w/o taxes & paypal)

Shumatec DRO-550

http://www.shumatech.com/web/products/dro-550/power-buy

DRO-550 Board (itself)

*all surface mount components pre-soldered

* extra's (below) are what needs to be soldered, (through hole/easy components)

$16.19 (extras)

http://www.shumatech.com/web/products/dro-550/power-buy

9 RED 7-segment LEDs $7.47

5 RED 3mm indicator LEDs $0.77

23 Keypad tact switches $4.14

23 Black tact switch caps $1.84

1 Program tact switch $0.17

2 2-pin MTA headers $0.13

5 3-pin MTA headers $0.44

5 4-pin MTA headers $0.58

5 2x2 Header $0.35

5 Shunt jumper $0.30

Parts needed to complete DRO-550 kit/build: (outside from above parts)

DRO-550 Specific:

$11.25

Hammond 1599HBK Unmachined Case:

http://www.wildhorse-innovations.com/in ... oductId=90

$17.99

DRO-550 Internal Cable Kit:

http://www.wildhorse-innovations.com/in ... oductId=89

$19.99 x 1

DRO-550 (speciic) Case - Machined:

http://www.wildhorse-innovations.com/in ... oductId=88

$14.99 x 1

DRO-350 Faceplate

http://www.wildhorse-innovations.com/in ... roductId=6

$1.75 x ??

Mini-Din Plug

http://www.wildhorse-innovations.com/in ... oductId=24

$12.99 x 1

AC Adapter - 9vdc @ 1.2a

http://www.wildhorse-innovations.com/in ... roductId=7

If you want to be 'ahead' of the game.. maybe contact

www.wildhorse-innovations.com

(I did) and they told me they were going to stock DRO-550 specific stuff this week..

just checked for ya..

cases, internal cables..DRO-550 specific..

for you.. you may want the un-machined cases..and do them yourself to fit whatever specs you want/like?

unmachined:

http://www.wildhorse-innovations.com/in ... oductId=90

DRO-550 internal cables:

http://www.wildhorse-innovations.com/in ... oductId=89

DRO-550 specific machined case:

http://www.wildhorse-innovations.com/in ... oductId=88

update on FINAL costs:

Fixed Costs

Item Estimated Cost

NRE (Stencils, SMT programming, PCB tooling) $1,785.00

Setup (Manufacturing setup) $342.00

Prototypes (2 development prototypes) $525.96

Subtotal

$2,652.96

Recurring Costs

Item Estimated Cost

Material (Raw parts costs) $47.42

Labor (Human labor costs) $30.08

Subtotal

$77.50

Extra Component Costs

Quantity Component

Estimated Cost

9 RED 7-segment LEDs $7.56

5 RED 3mm indicator LEDs $0.25

1 Piezo Buzzer $1.28

23 Black tact switch caps $1.61

1 Program tact switch $0.33

2 2-pin MTA headers $0.08

5 3-pin MTA headers $0.30

5 4-pin MTA headers $0.40

5 2x2 Header $0.85

5 Shunt jumper $0.25

Distributor Shipping + Kitting Supplies (TBD) $2.00

Total

$14.91

Per-Board Costs (With Extra Components)

Item Estimated Cost

Fixed $4.82

Recurring $77.50

Extra Components $14.91

PayPal (3.9% + 2 x $0.30) $4.58

Total

$101.82

Per-Board Costs (Without Extra Components)

Item Estimated Cost

Fixed $4.82

Recurring $77.50

PayPal (3.9% + 2 x $0.30) $3.97

Total

$86.29

----------------------------------------------------------------

Adding some links and what not that we can use to refer back on when we get these things..

I want to be able to use this to its FULL potential..

I think once I get my mill..the bolt hole pattern feature will be a featured used quite often by me.

some of links will be to DRO-350 stuff.. user guides..etc.. because I feel useful info will still be there..

also some of these are un-official guides NOT form the developer (but were highly recommended)

I think the Users Guide of the DPU-550 will be the closest for what is in the DRO-550...Users Guide (which is coming any day now)

Rick Sparber: (unofficial docs)

http://rick.sparber.org/sh.htm

Shumatec: DRO-550 Hardware Manual

http://groups.yahoo.com/group/ShumaTech ... Manual.pdf

DRO-350 Users Guide: The official DRO-350 User's Guide for software release 4

http://www.shumatech.com/products/dro-3 ... /guide.pdf

DPU-550 User's Guide: Daughter board to DRO-350

http://www.shumatech.com/products/dpu-5 ... RO-550.pdf

Chinese Scales:

A technical descrition of the Chinese scale protocol and their operation.

http://www.shumatech.com/support/chinese_scales.htm

The Chinese Scale Experience

Bill Havins, a user of the ShumaTech DRO-350, wrote a great article on his experiences using Chinese scales. The artice covers where to purchase Chinese scales, their installation on equipment, and general troubleshooting.

http://www.shumatech.com/support/Chines ... rience.pdf

OPEN DRO Project:

http://opendro.sourceforge.net/

a nice feature/add-on was posted about using the two extra axis for a min LCD screen..

looks trick..

http://www.shumatech.com/web/products/lcd-200

----------------------------------------------

ok boys...

I know Alan, Erv & Goodman all got these DRO's (or are coming soon)..

they overlays on the shumatech sites are available now..as wella sthe LCD add-on kit (and overlay for that as well)

that being said.. I gave it a shot at making my own overlay..

and Im releasing it here for anyone lse that may want to use it.. or in fact edit it..as I am including the source .psd file as well.

Also included in the .psd is the BASE TEMPLATE for the enclosure milling specs (where the cut outs are)

alternately.. if anyone wants something custom done.. just let me know.. (ie: diamond plate background...... or you companies name in the corner.. different color scheme.......whatever)

this first version was me trying to be minimal and clean..

it is based off of my first 'mock-idea' (and is almost identical)

hope you guys like it.. (working a backlit idea/version currently)

http://dmstudios.net/misc/DRO-550/DRO-5 ... inimal.zip

-------------------------------------------------------------------------------------------------

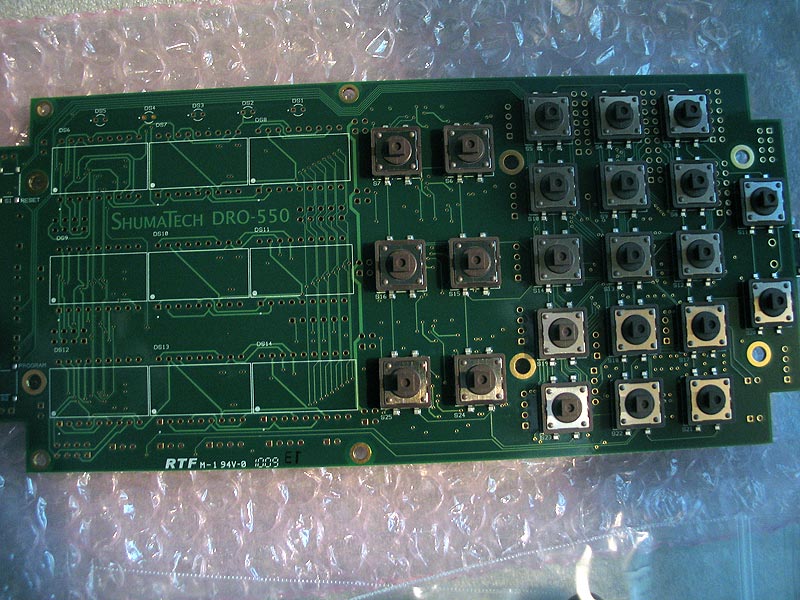

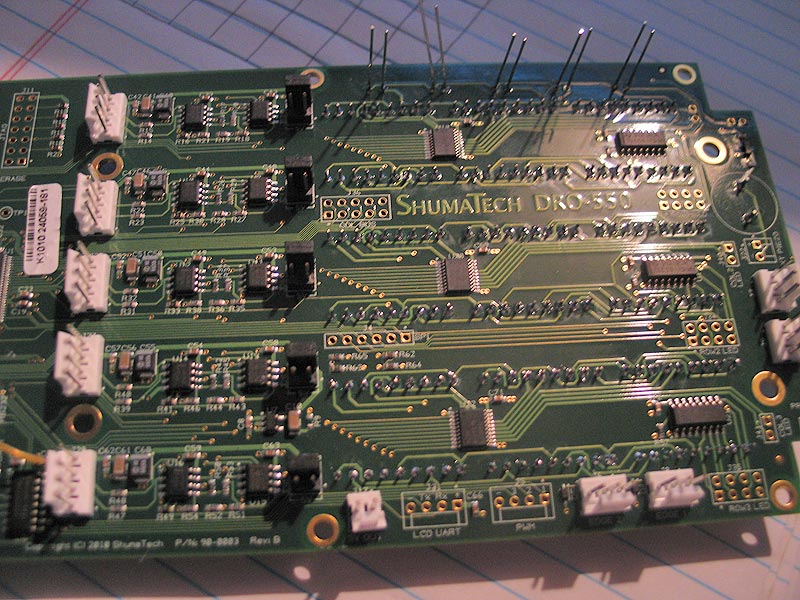

my DRO-550 arrived..packed nice..and no problems so far..

still need to order my case/enclosure..internal cables..etc..

but the MAIN portion is here (I got two of them)

the 'kit' pic: (sorry its blurry)

top:

bottom:

man..getting those SMD components installed for us..and the buttons too for an extra $4 was WELL worth it..LOL

there are some polls up for some of the overlays..and some other questions (if you guys are interested)

I think by default..they come with RED numeric displays... anyone changing to green? (they look sharp).. or another color? I have been able to find a BLUE in the same package/footprint as the one for the DRO-550 uses.

figured Id post with the first update..Im curious to watch and discuss others builds too..

-------------------------------------------------------------------------------------------------------------------------

took some time last night.. to finally look into things more..

Im excited..and this 'project' looks very fun.

I have gathered the files needed for everyone else..

here are the links as well (which I recommend..they step by step walk you trough set-up)..

Construction:

http://www.shumatech.com/web/products/d ... nstruction

PDF:

http://groups.yahoo.com/group/ShumaTech ... 0Guide.pdf

Software:

http://www.shumatech.com/web/products/dro-550/software

PDF:

http://groups.yahoo.com/group/ShumaTech ... 0Guide.pdf

Hardware:

http://www.shumatech.com/web/products/dro-550/hardware

PDF:

http://groups.yahoo.com/group/ShumaTech ... Manual.pdf

OpenDRO Software:

http://sourceforge.net/projects/opendro/files/

SAM-BA:

http://www.atmel.com/dyn/resources/prod ... 0v1.13.exe

(Im also really diggin' this LCD add on for the other extra functions/axis..etc)

http://www.shumatech.com/web/products/lcd-200

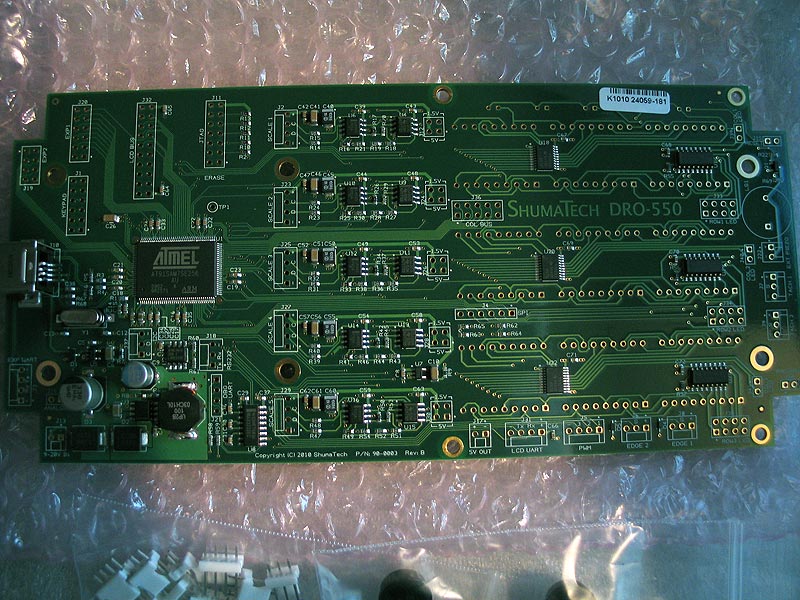

I took out 1 of my boards last night.. grabbed the "Construction Manual" (linked to above)

had done all prelim tests

(measured resistance at certain spots)

soldered in ALL headers & tact switch

hooked it up to my PSU using 9V @ 1.5A

metered certain points to check 5v, 3.3v, 1.5v, 1.8v, etc (all was perfect)

hooked up to USB port.. installed drivers to recognize chip/board

installed SAM-BA (linked to above)

flash Atmel chip

verified write

(everything was perfect)

I did all of this in about 30 minutes or.. I glanced over the documentation while cleaning up after dinner. knew what I needed.. (already had files downloaded & documentation printed out in binder as well)..

and that was that.

Im 'very' happy with not only the quality, but documentation as well.

This is EASY!!!!

I have NOT installed my display LED's for two reasons:

1.) I do not have an enclosure yet.. and I want to make sure I mount them to be flush and display/light well behind the overlay.

2.) Im not 100% sure I sticking with the ALL RED display LEDS..

(I have been looking for some BLUE one....anybody?)

but may get all green.. or even multi-color.

(ie: 1 color for each axis, X-red, Y-green, Z-amber)

also we can make our own custom overlays as well..the group has been having polls on tons of different versions..

I'll try and post some more pics..

-----------------------------------------------------------------------------------------------------------

I still have NOT ordered my case and internal cable kits..etc (nor scale plugs or power adapter)

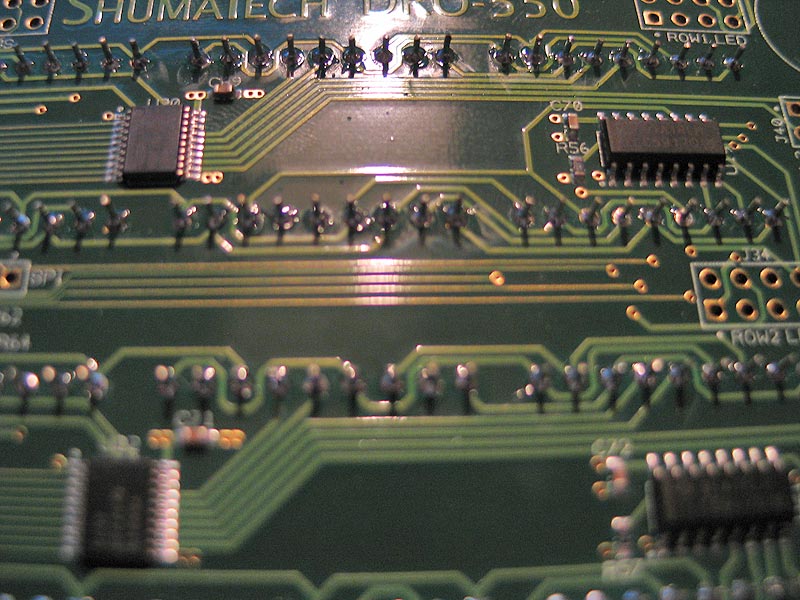

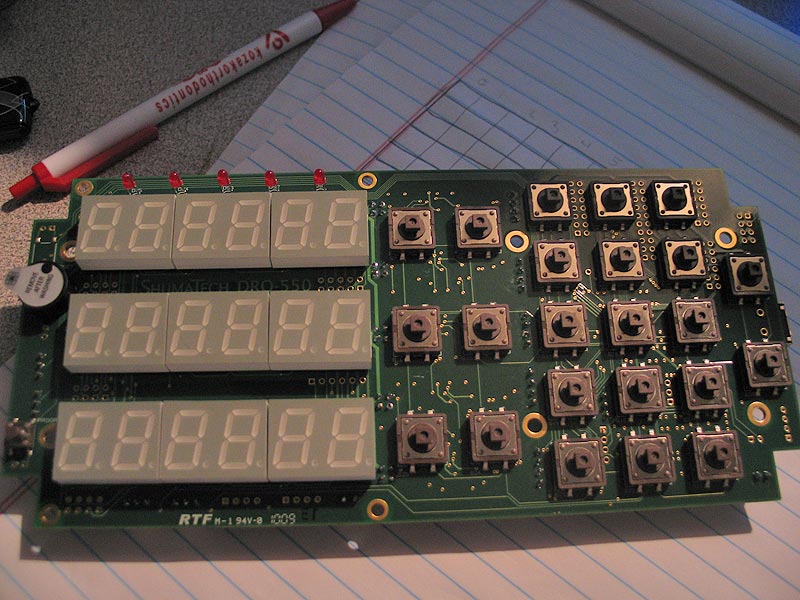

anyways here are some pics.. the basic construction will take less than 1 hour.. (less on second units) people who posted it 'only' taking them 3 hours... I was thinking thats not too bad... but now Im like..what the fuck were they doing?

nothing but a ton of headers with through holes to solder to.

check out my soldering.. (not too bad) ![]()

all the headers (overview)

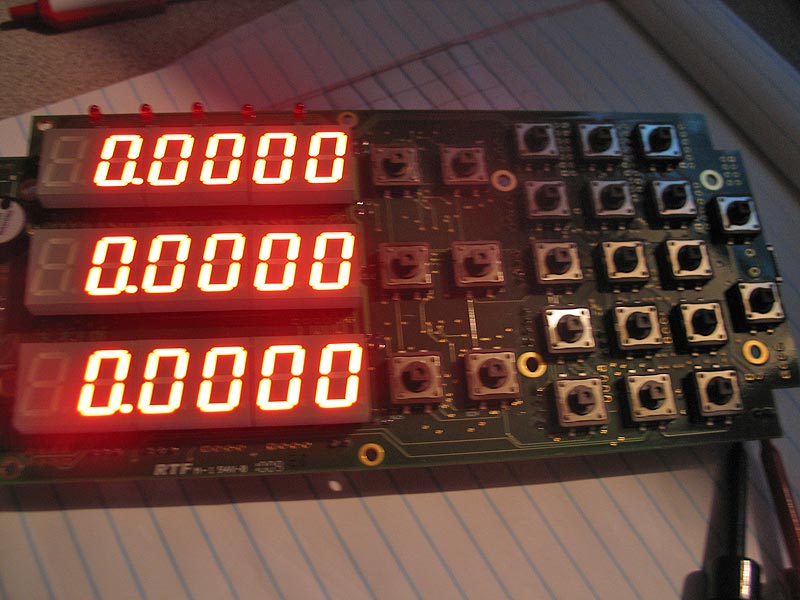

there she is:

and lit-up:

man there is 162 solder 'joints' to do on the 9 x 7-segment led displays!! plus all the headers! hahaha

here was my submission to the overlay poll/post

can buy order one of the new ones... or make your own at a kinkos or whatever if you want custom color scheme or whatever.. there was some nice ones posted too

-----------------------------------------------------

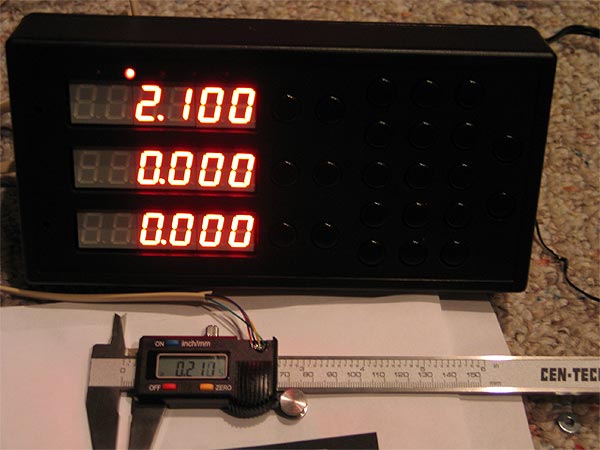

All completed.. (the first one at least)..

the second is all soldered up..just need to assemble case and attach internal cables!

Im digging it so far!

Im making my own overlays..so if anyone wants to file(s)..let me know.

test scale I made..using $9.99 HF caliper...

the first overlay Im finishing up.. (all 300 DPI .jpg's..with included source .psd file)